|

Note: You must be registered in order to post a reply.

To register, click here. Registration is FREE!

|

| T O P I C R E V I E W |

| pg265 |

Posted - 10/24/2020 : 05:53:50

Hi ,

It’s been a long time since my last post...

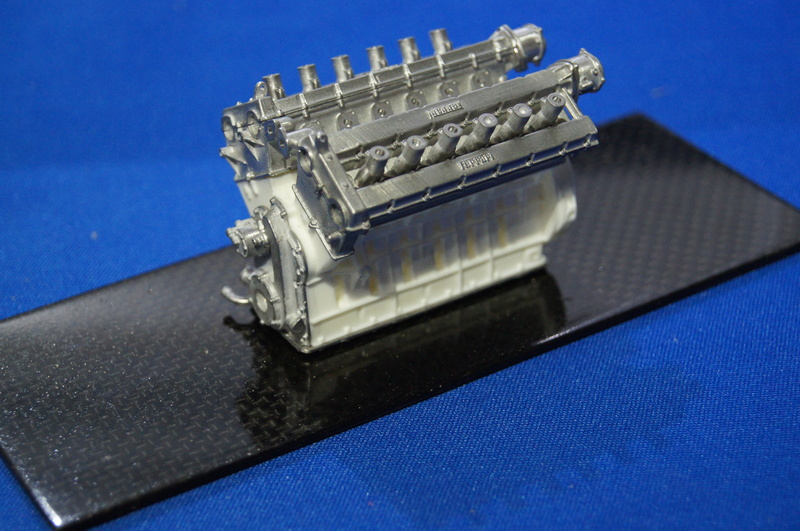

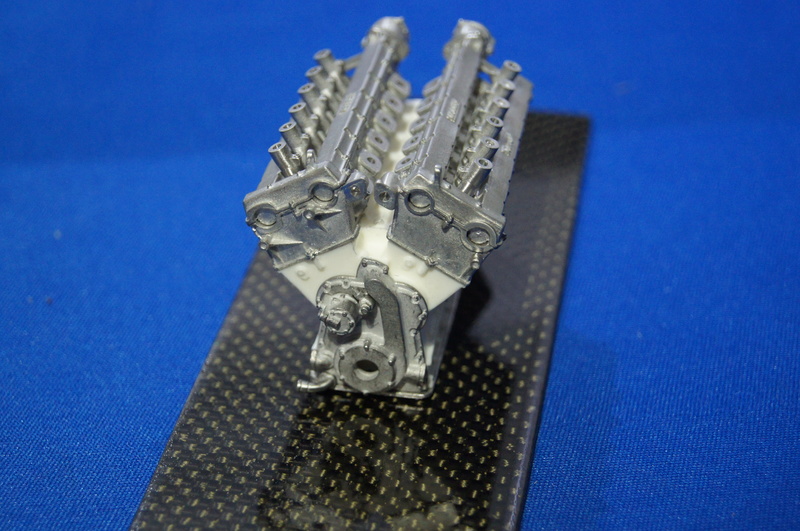

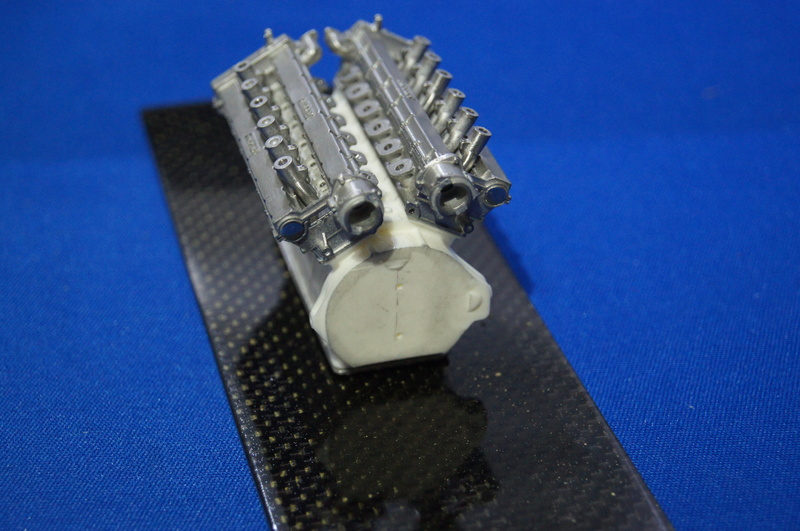

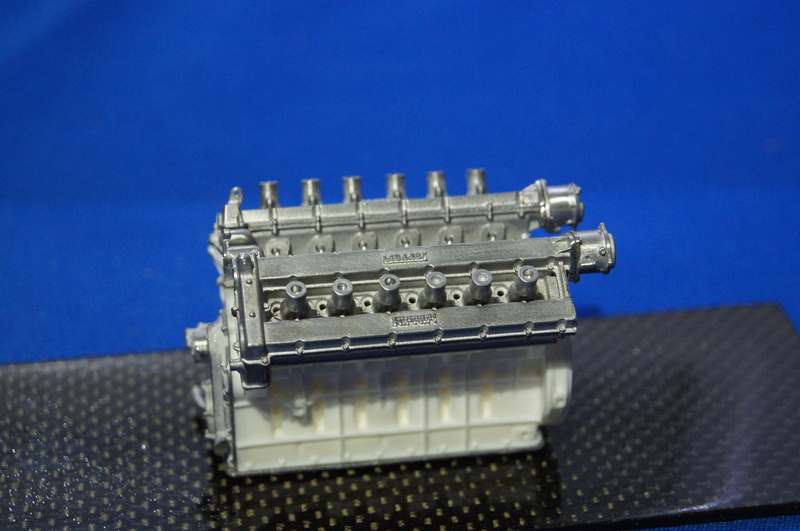

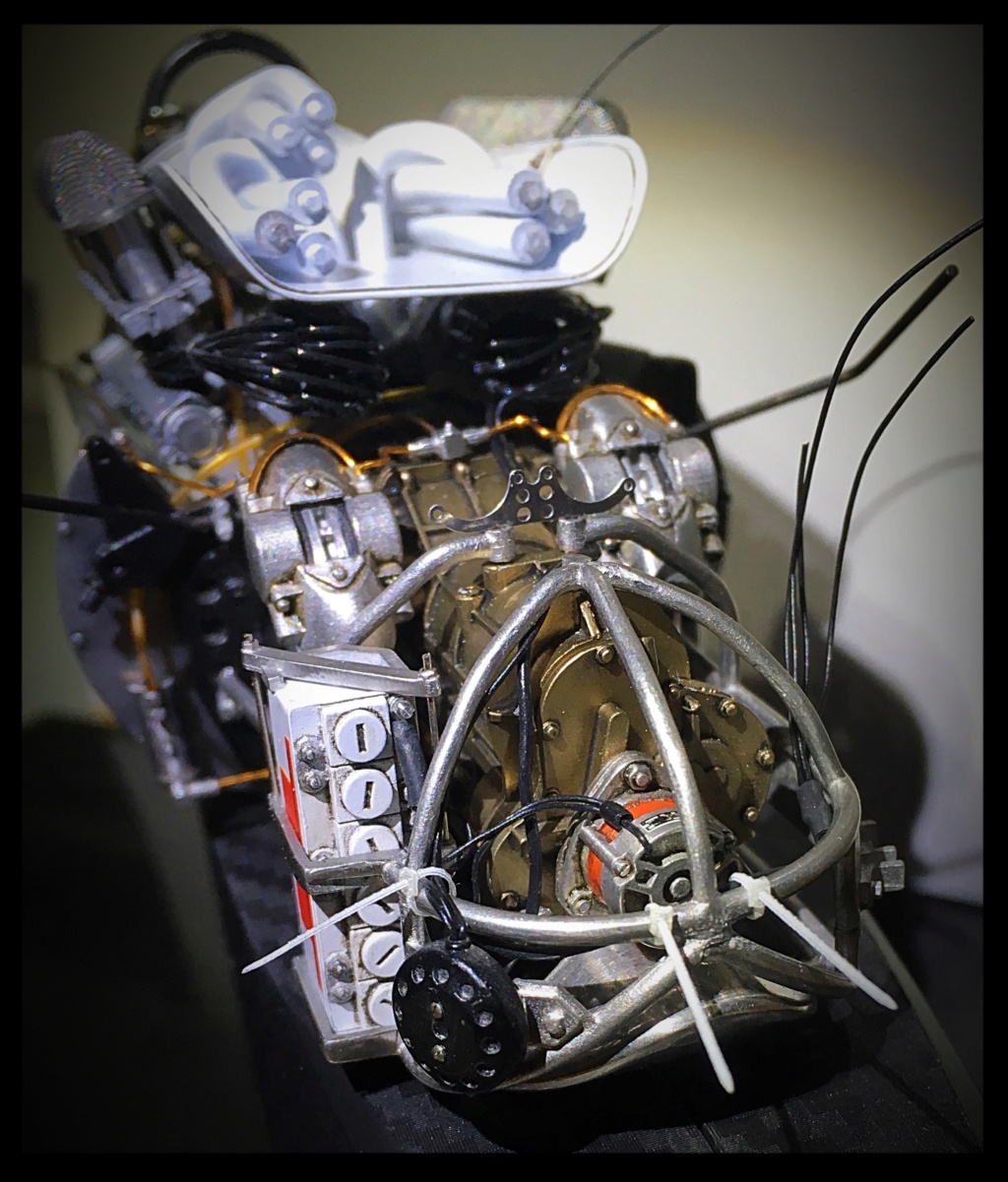

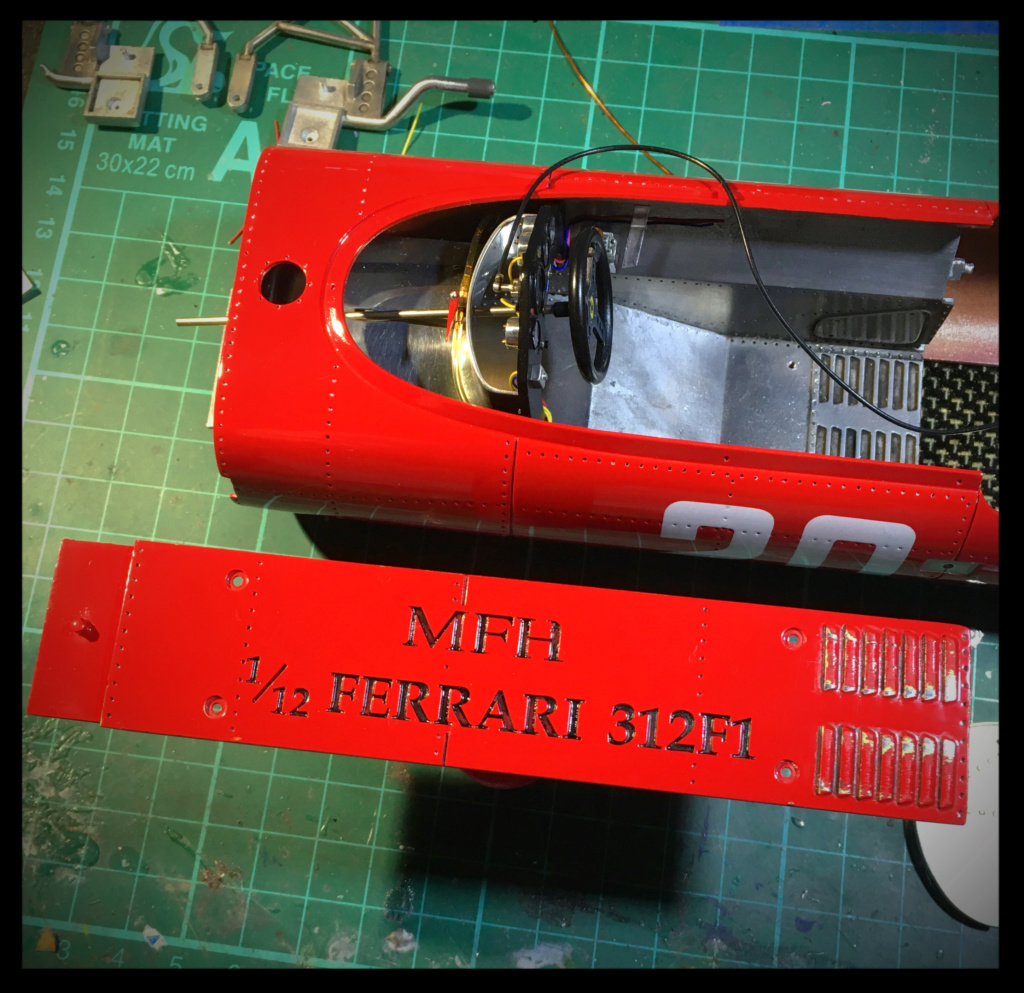

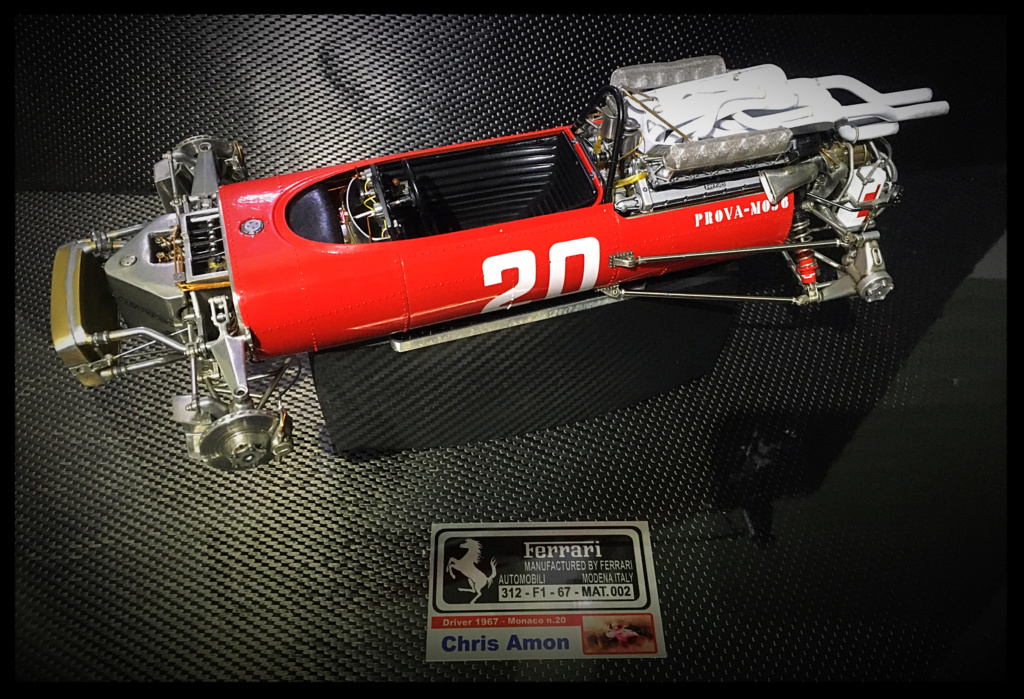

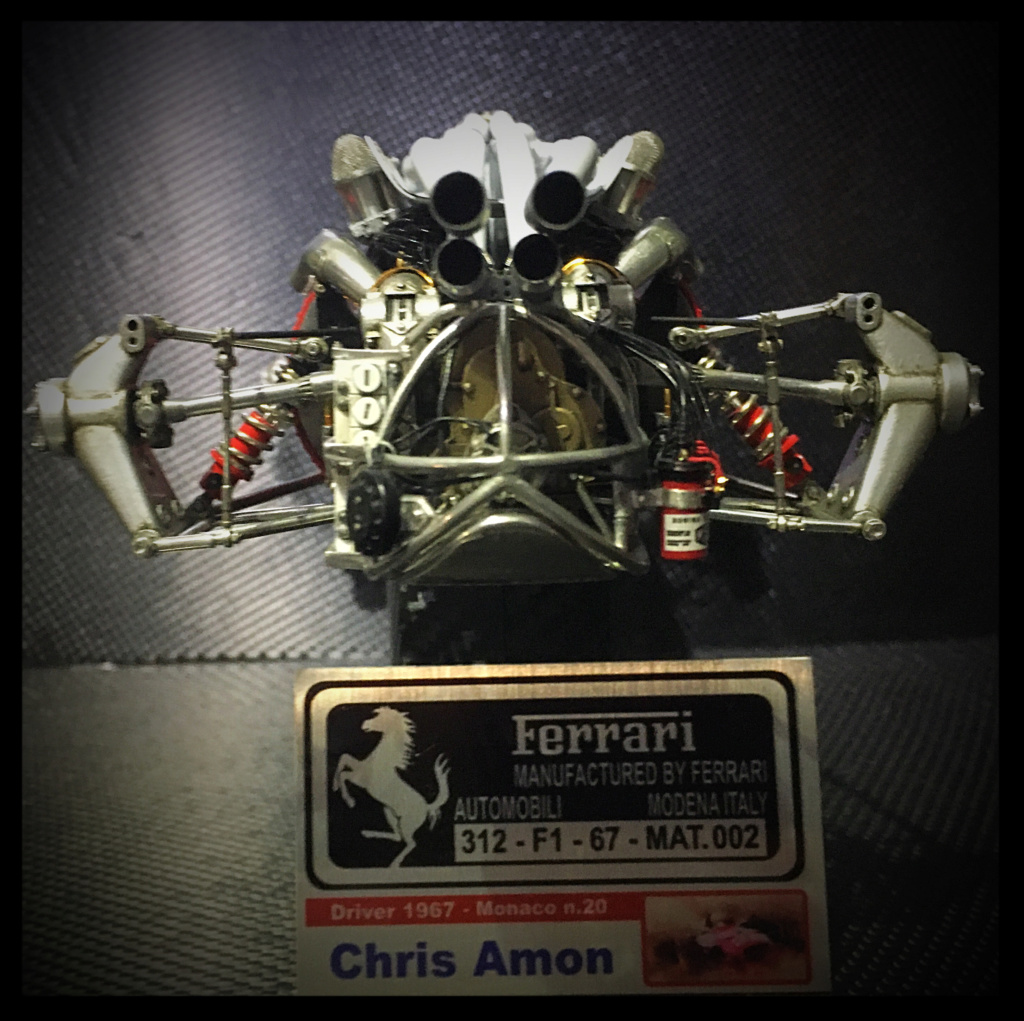

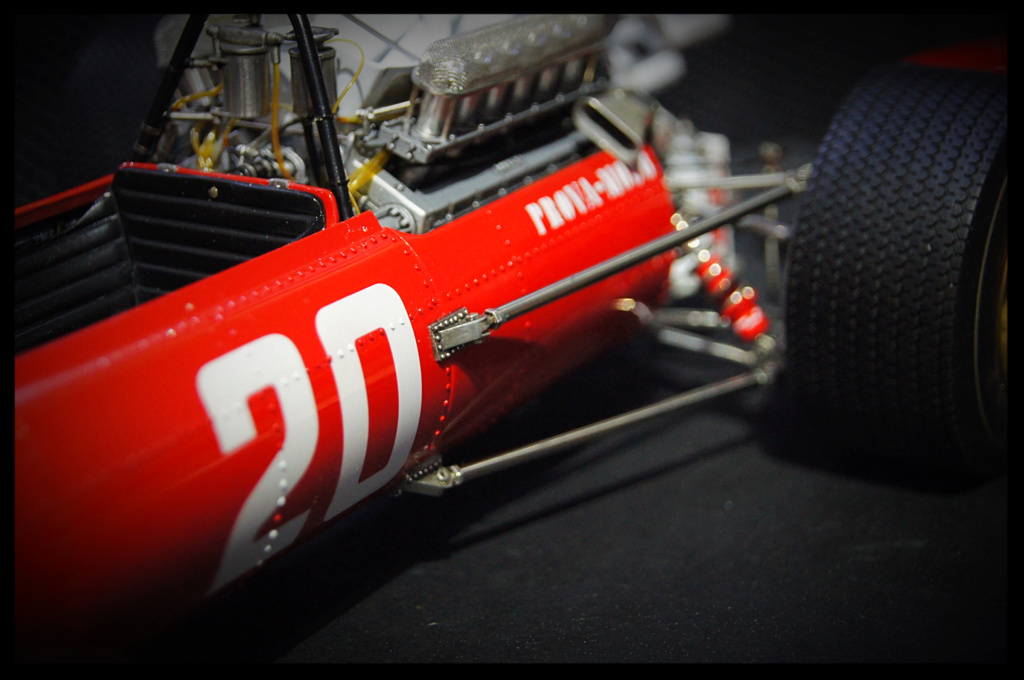

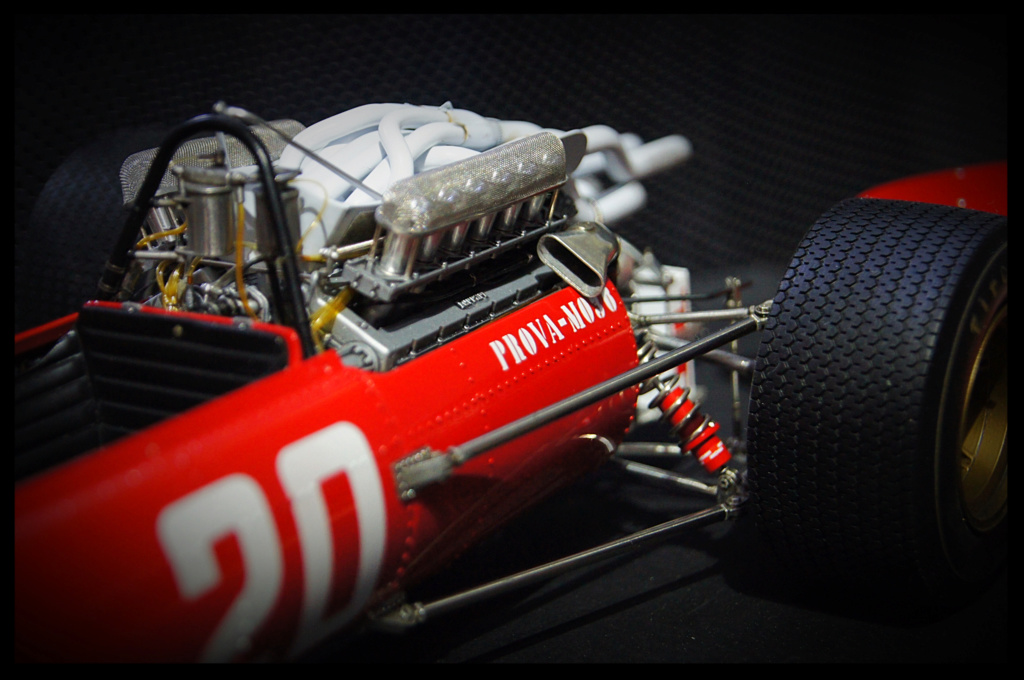

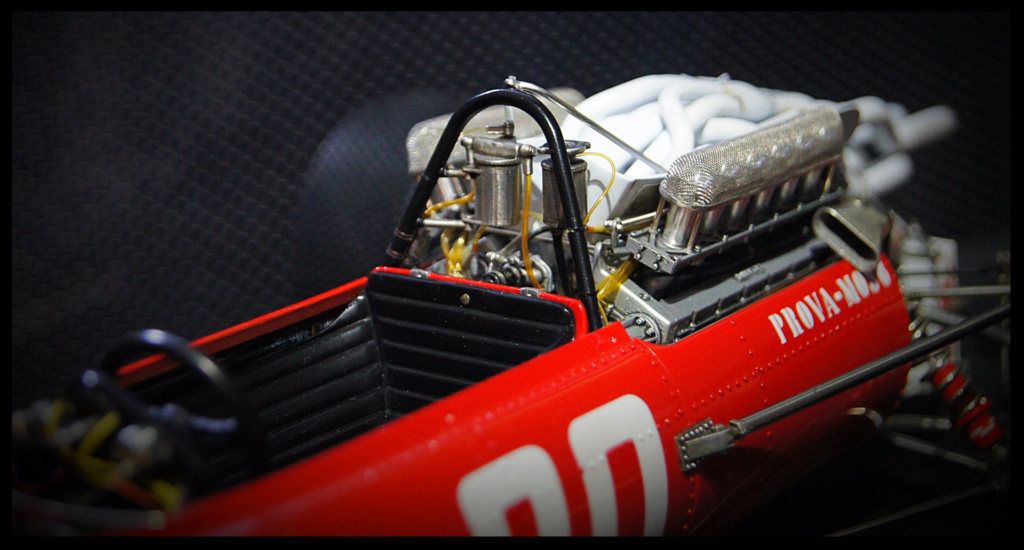

A new Formula 1, from 1967 (Great year!)

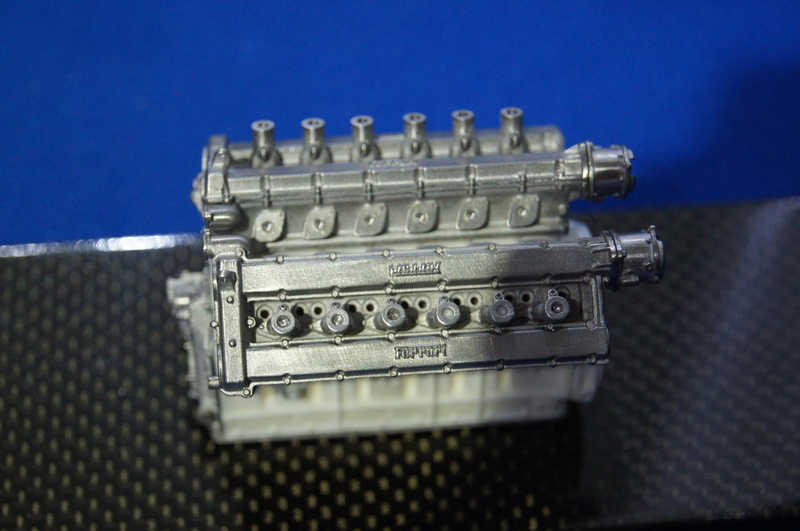

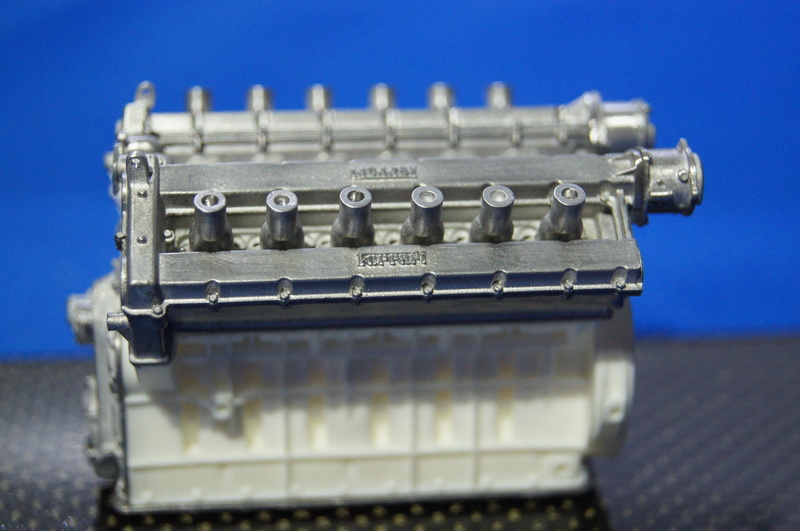

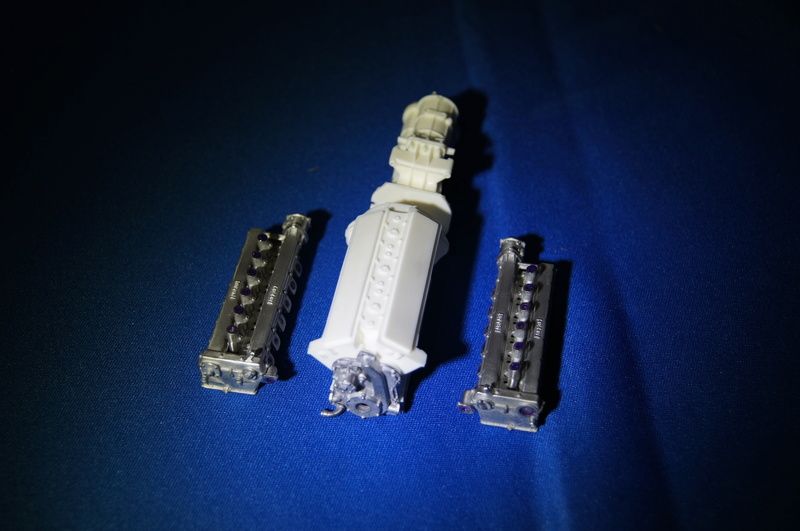

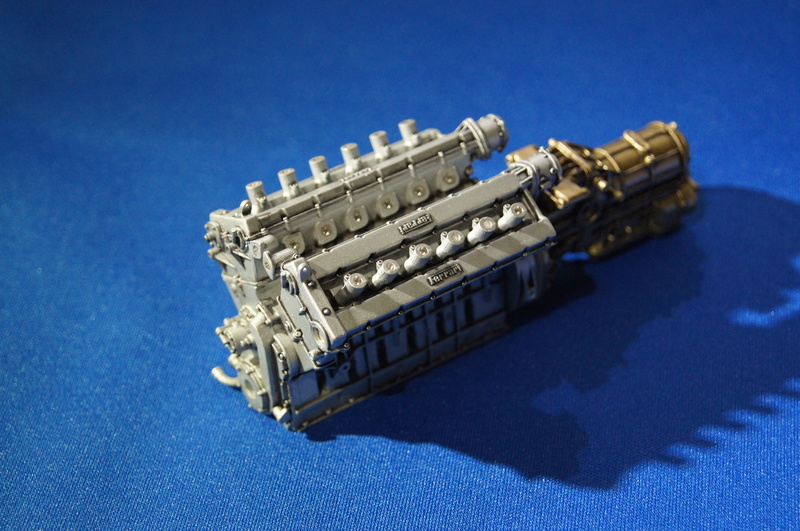

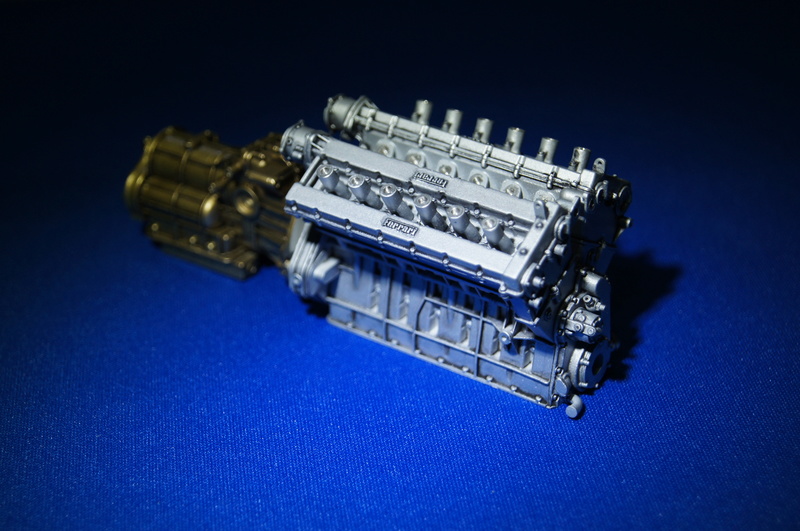

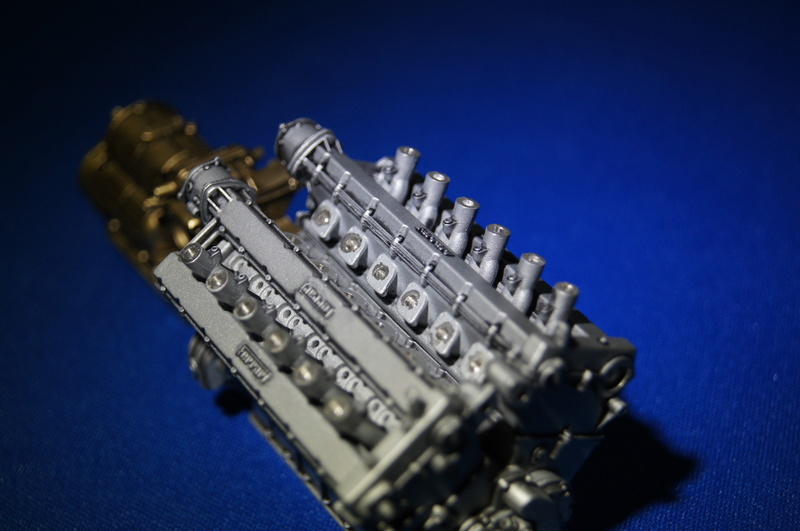

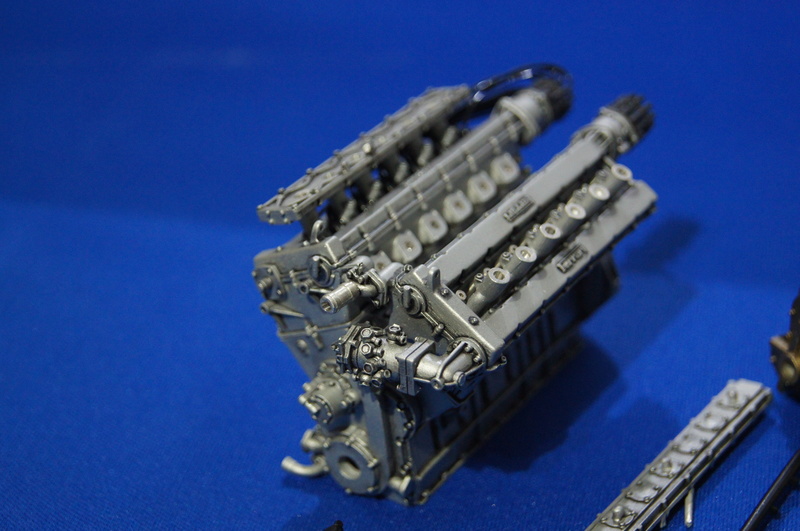

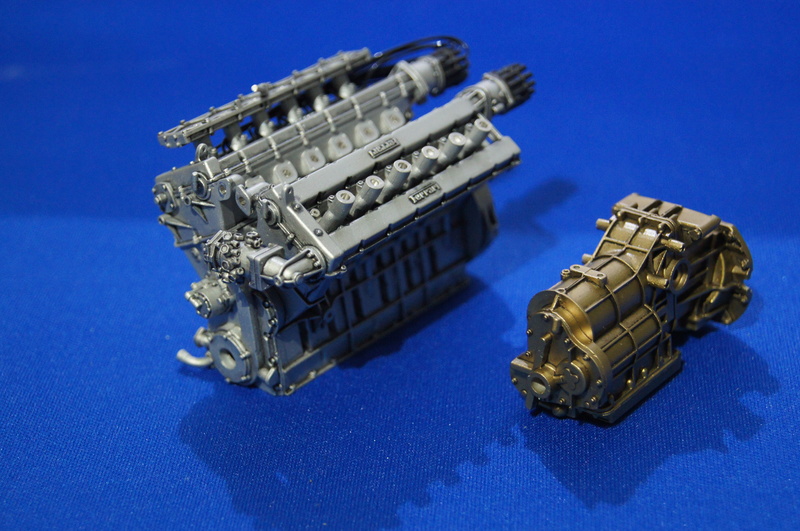

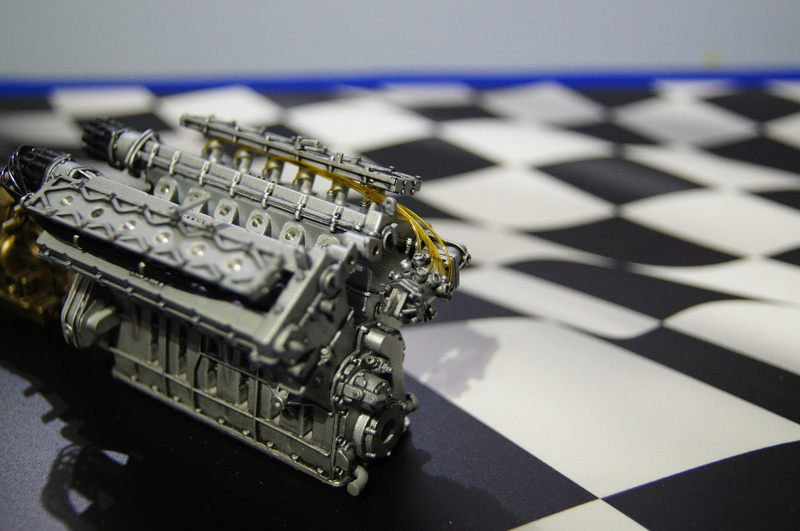

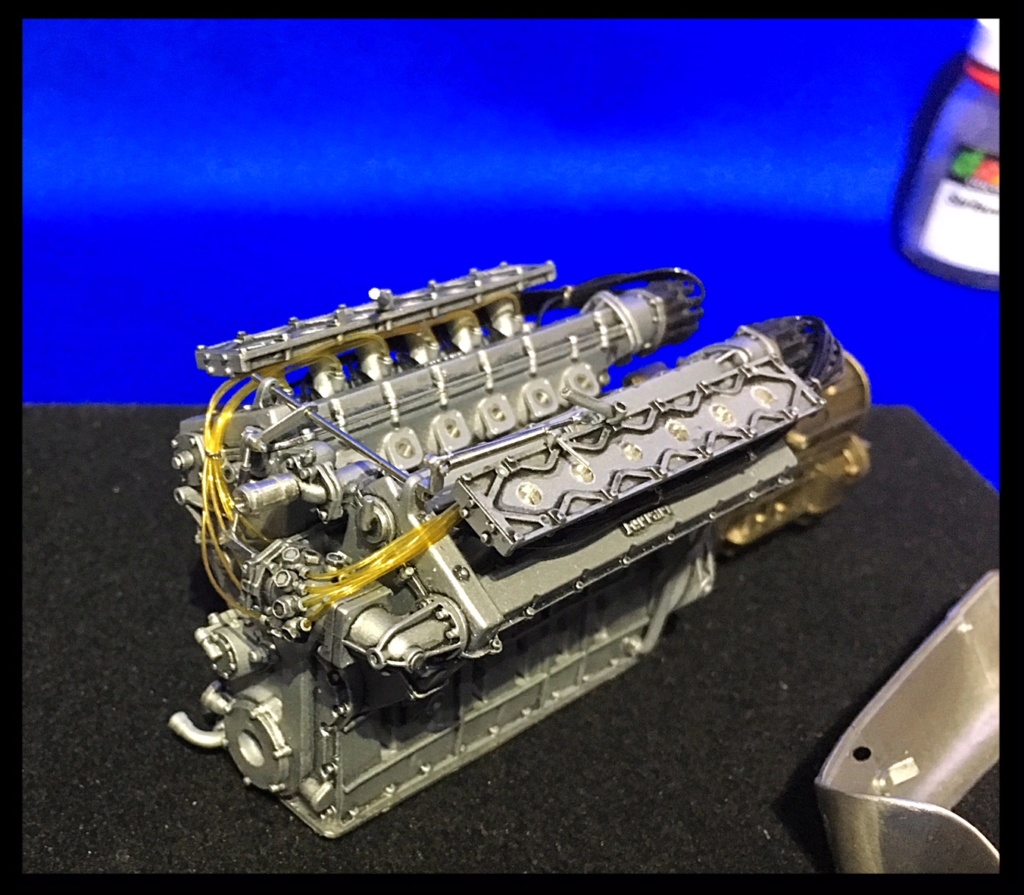

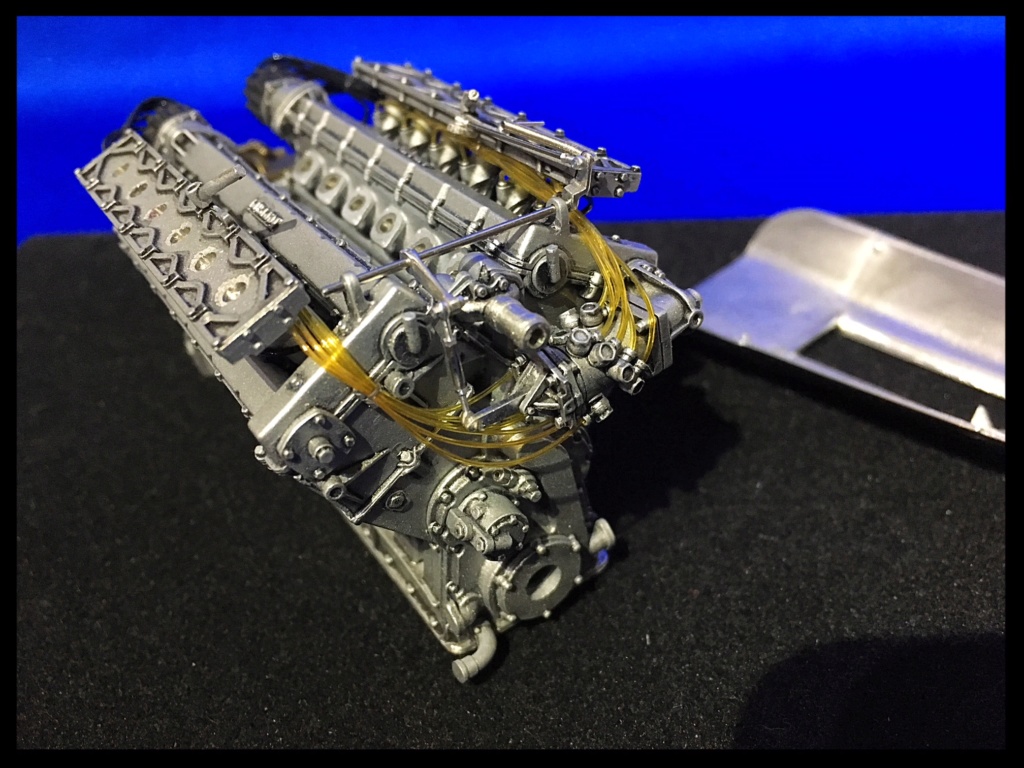

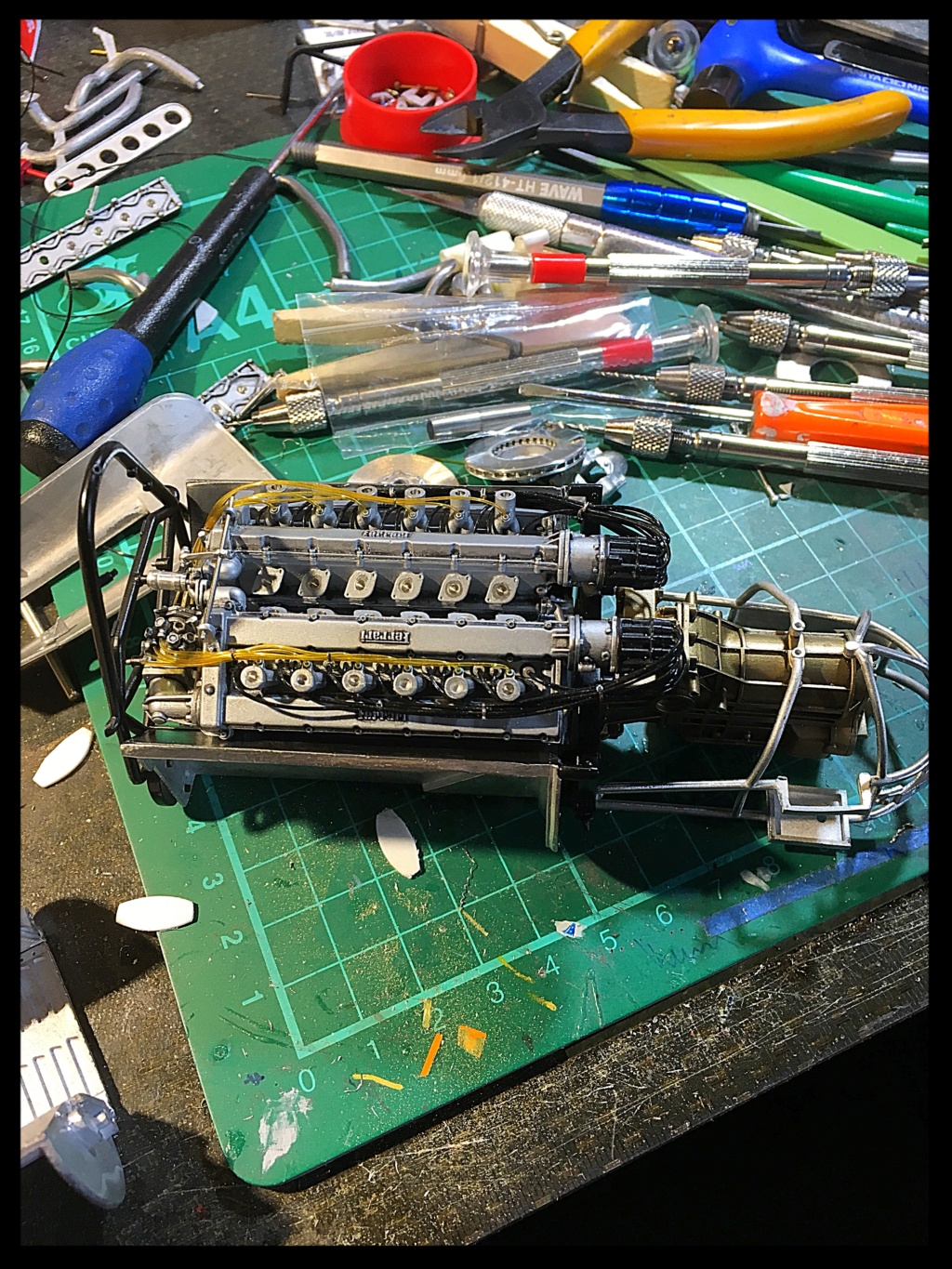

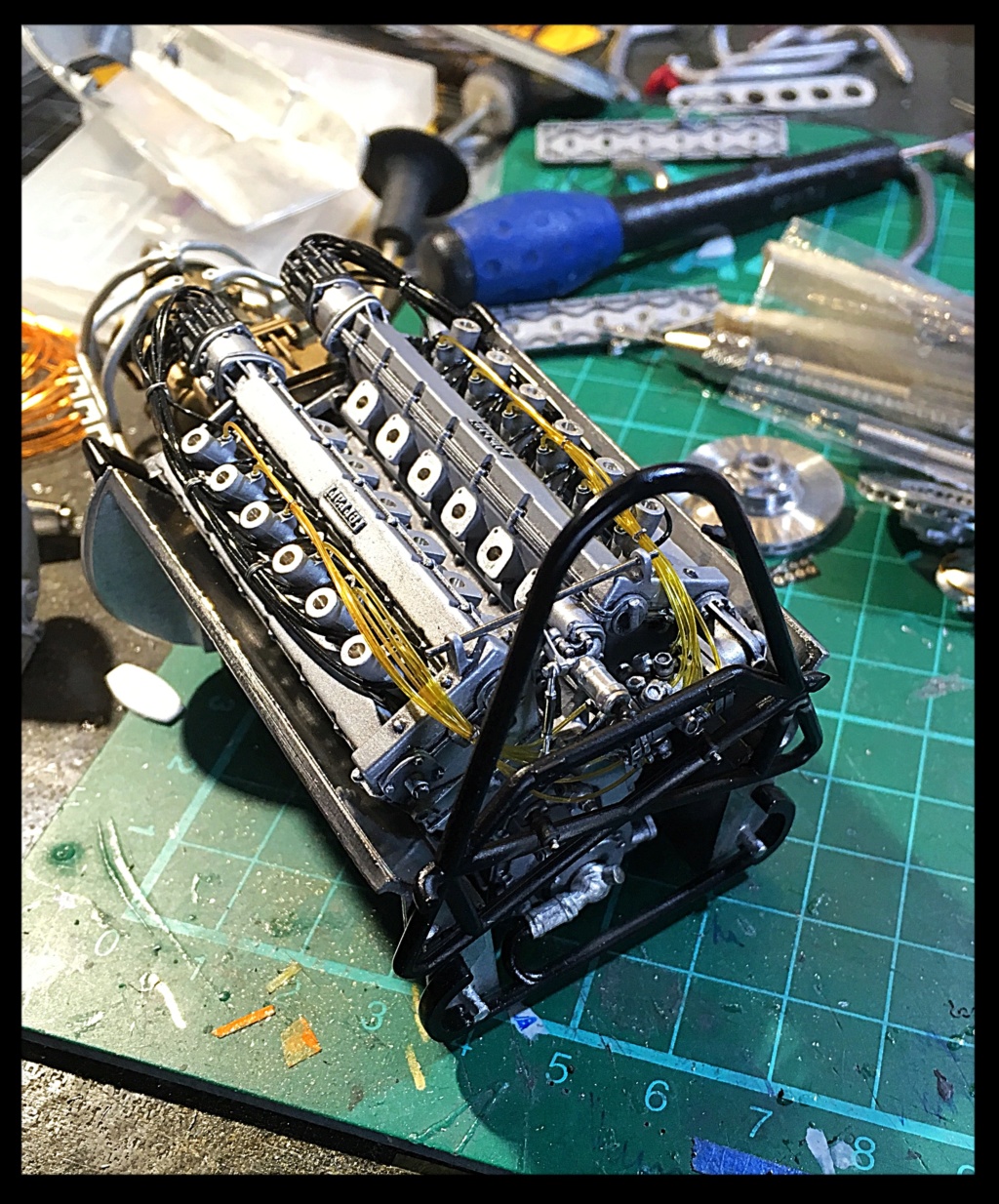

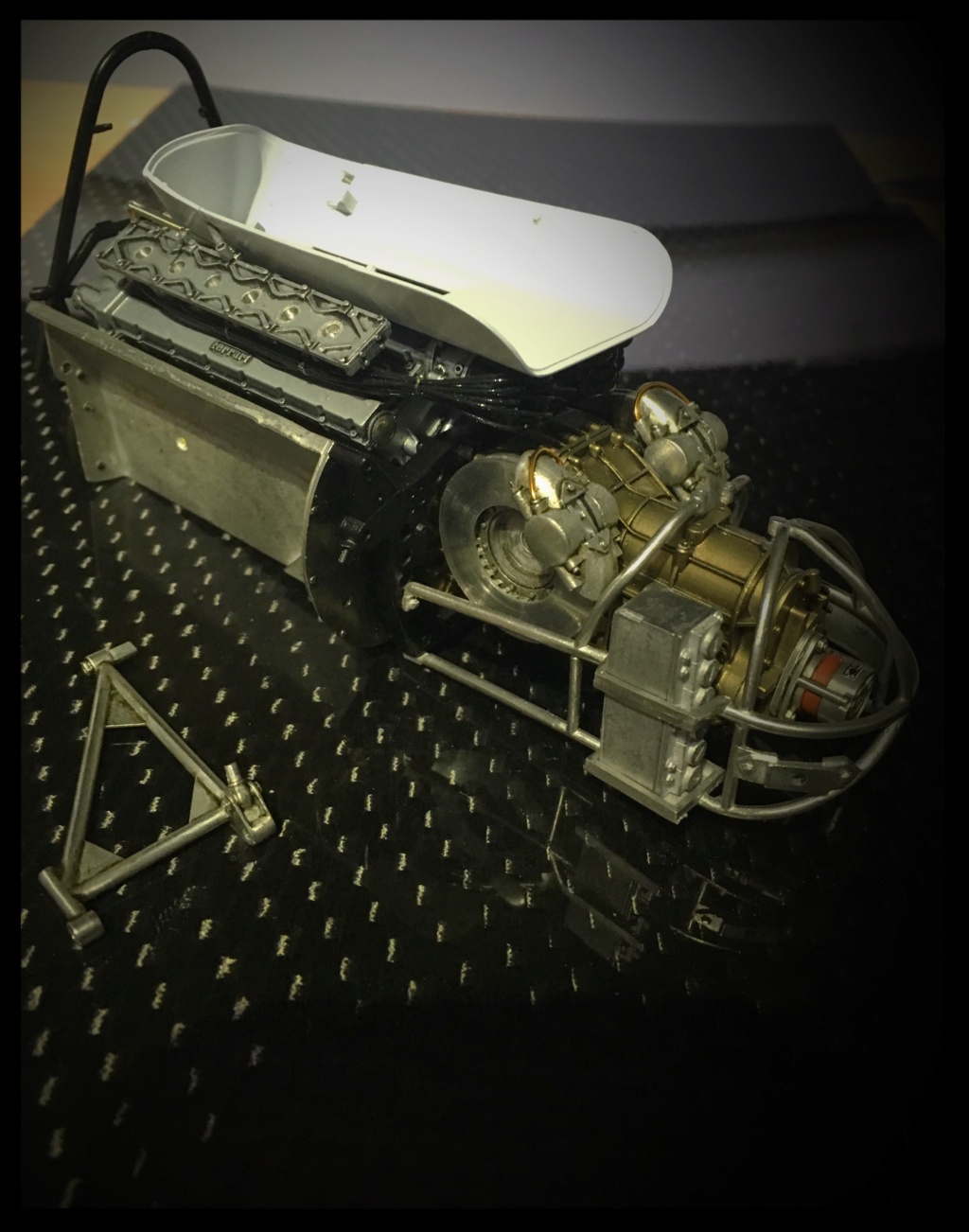

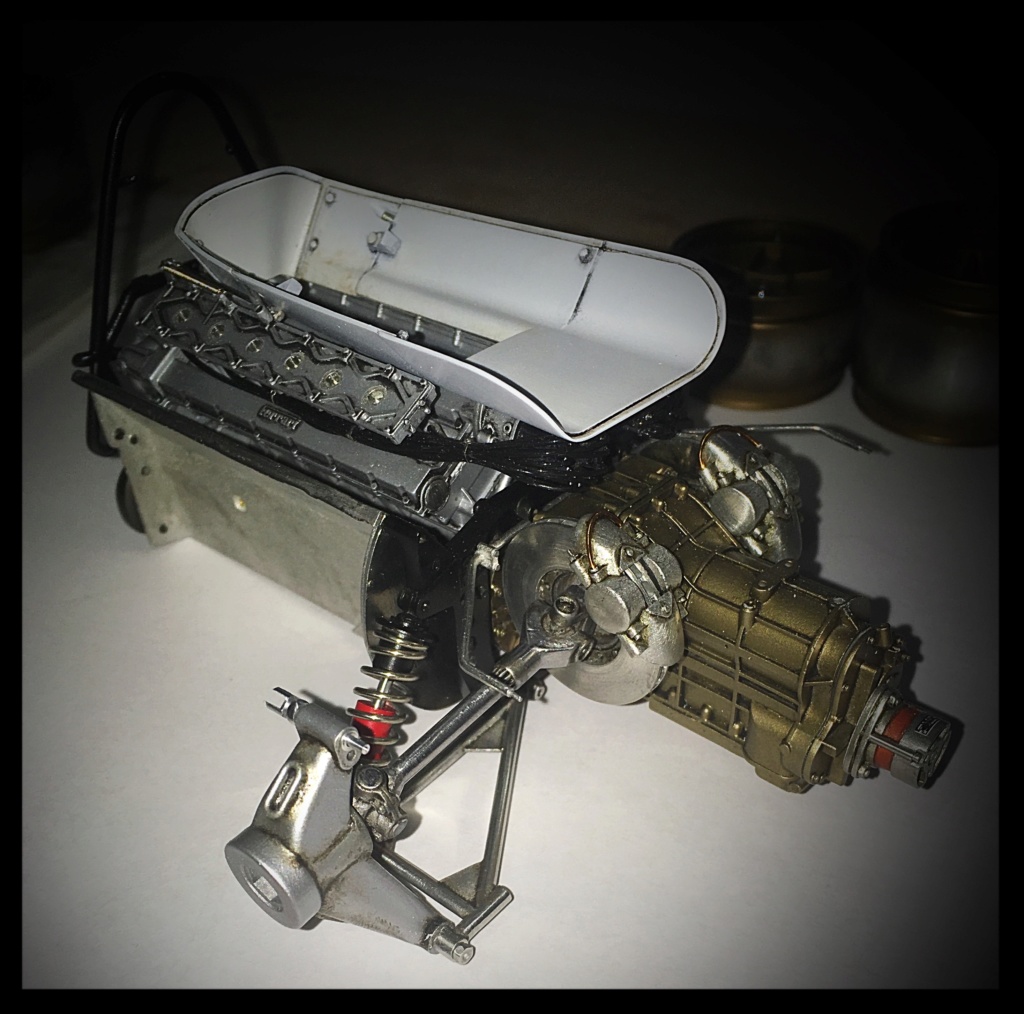

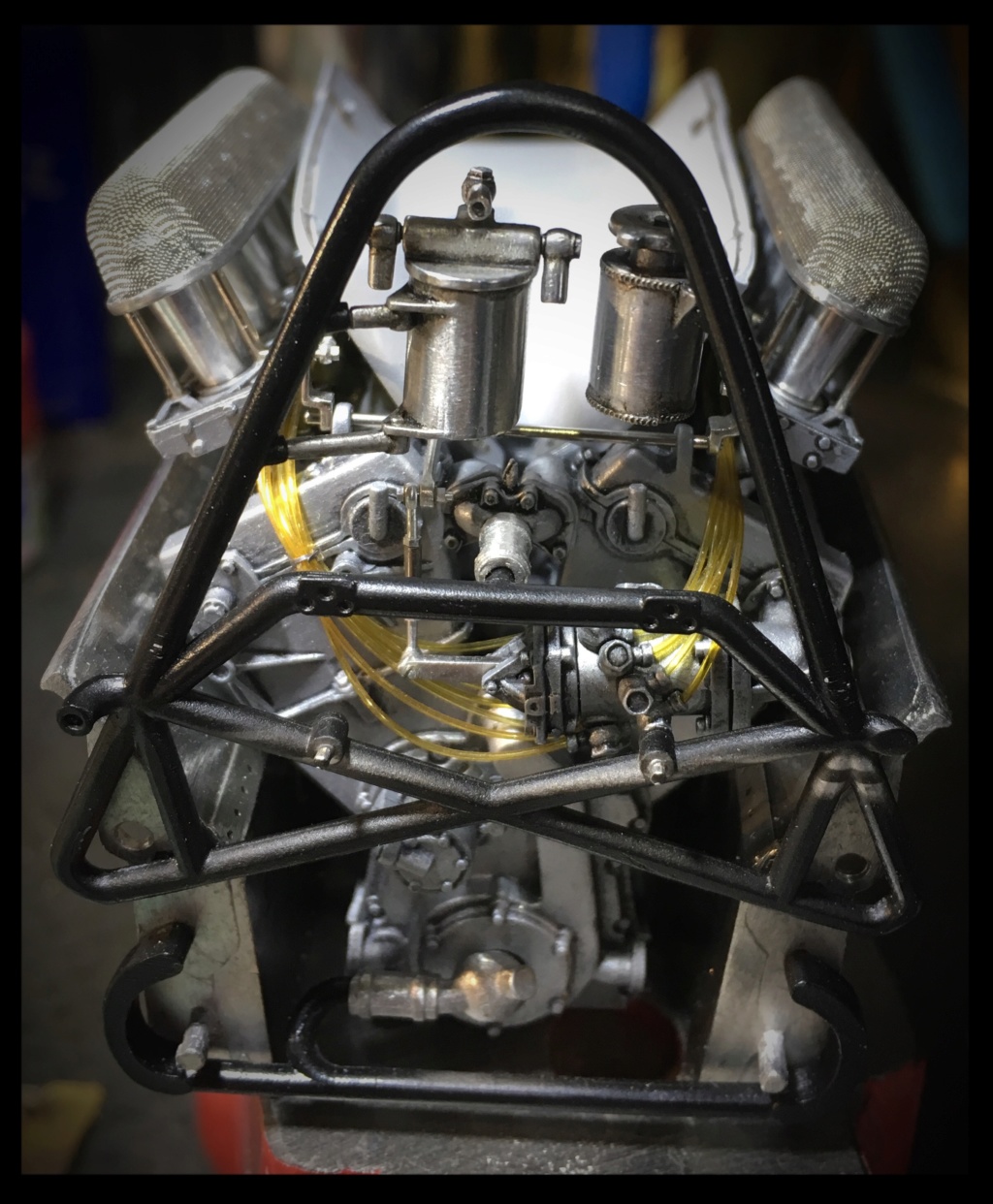

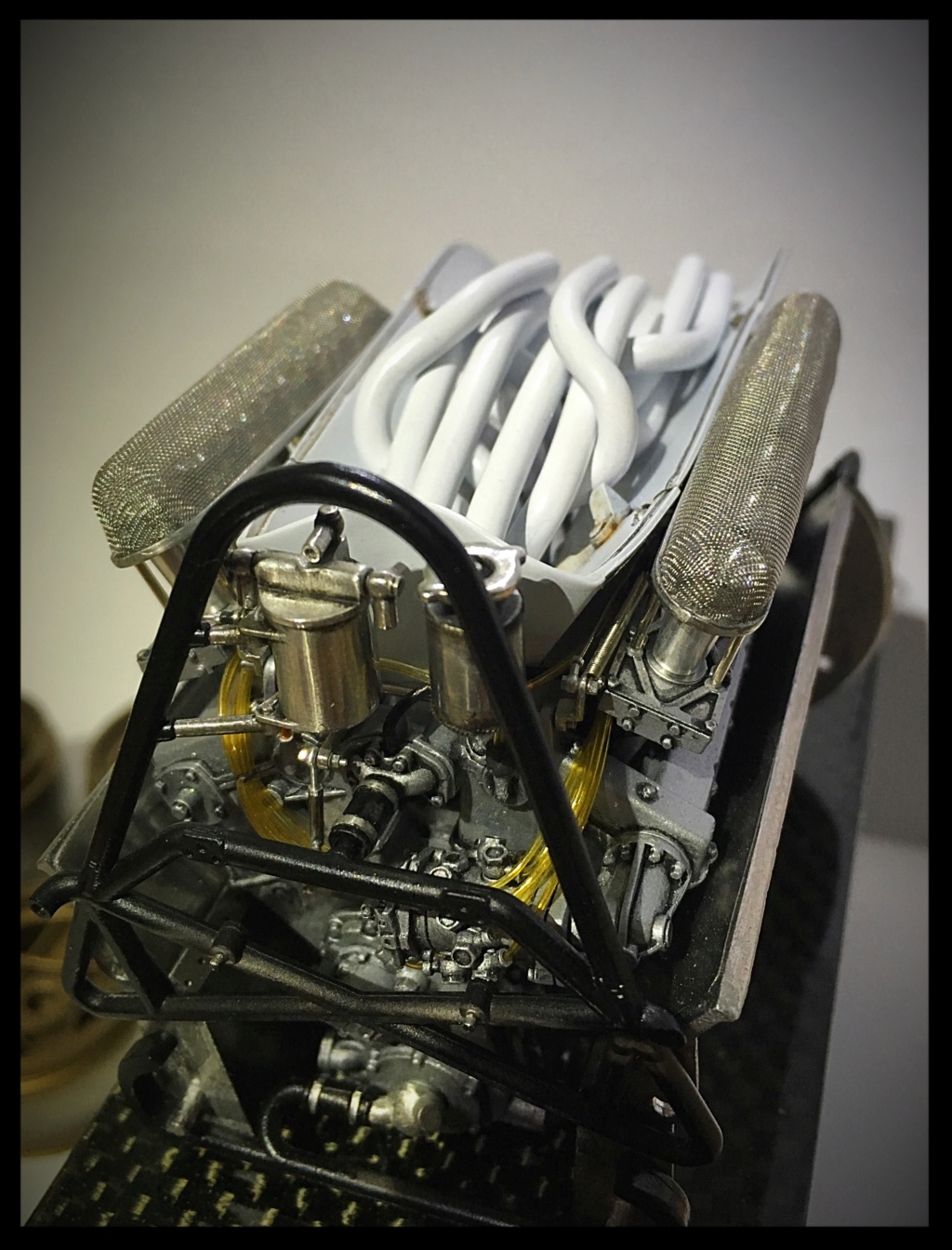

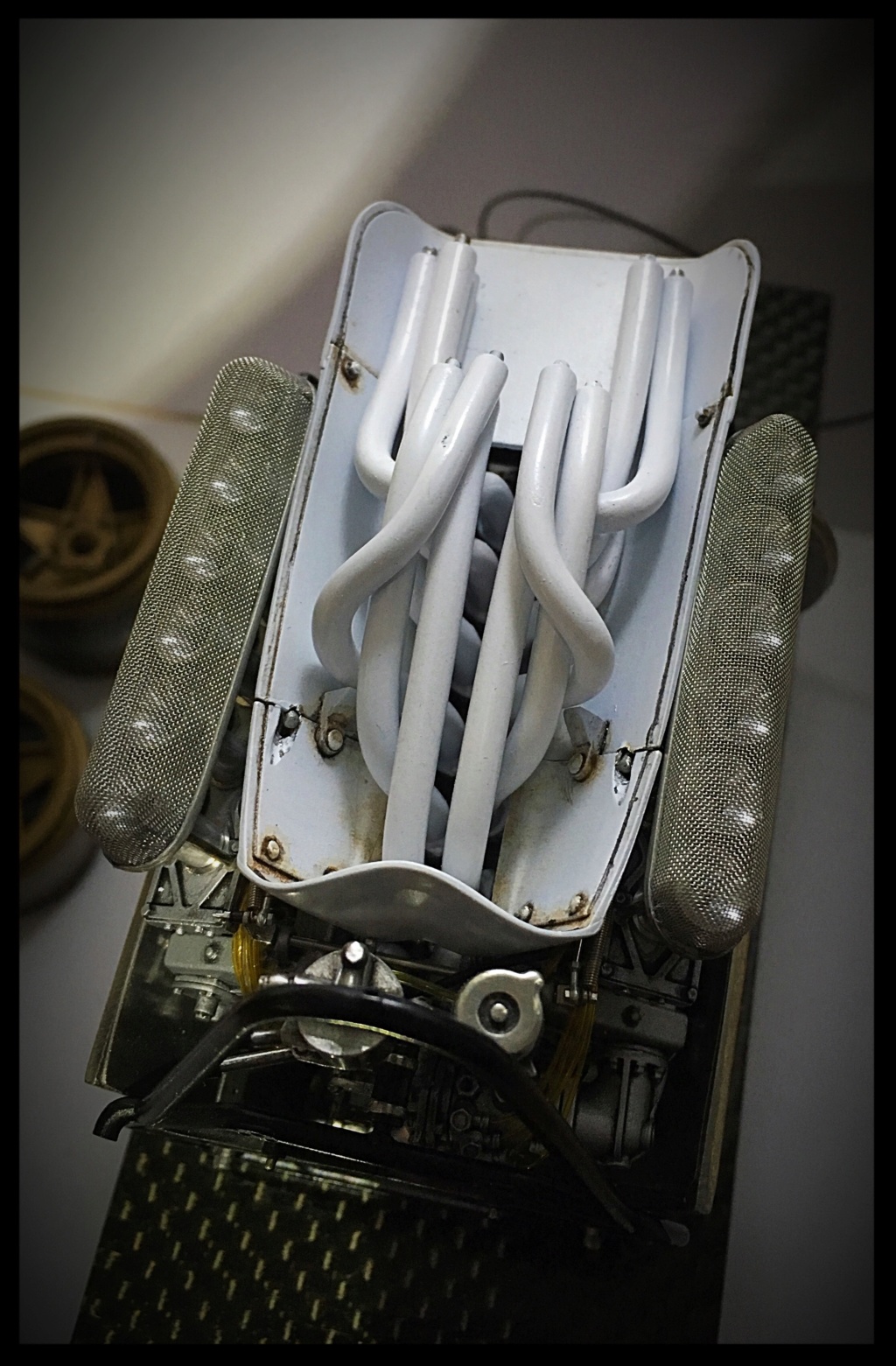

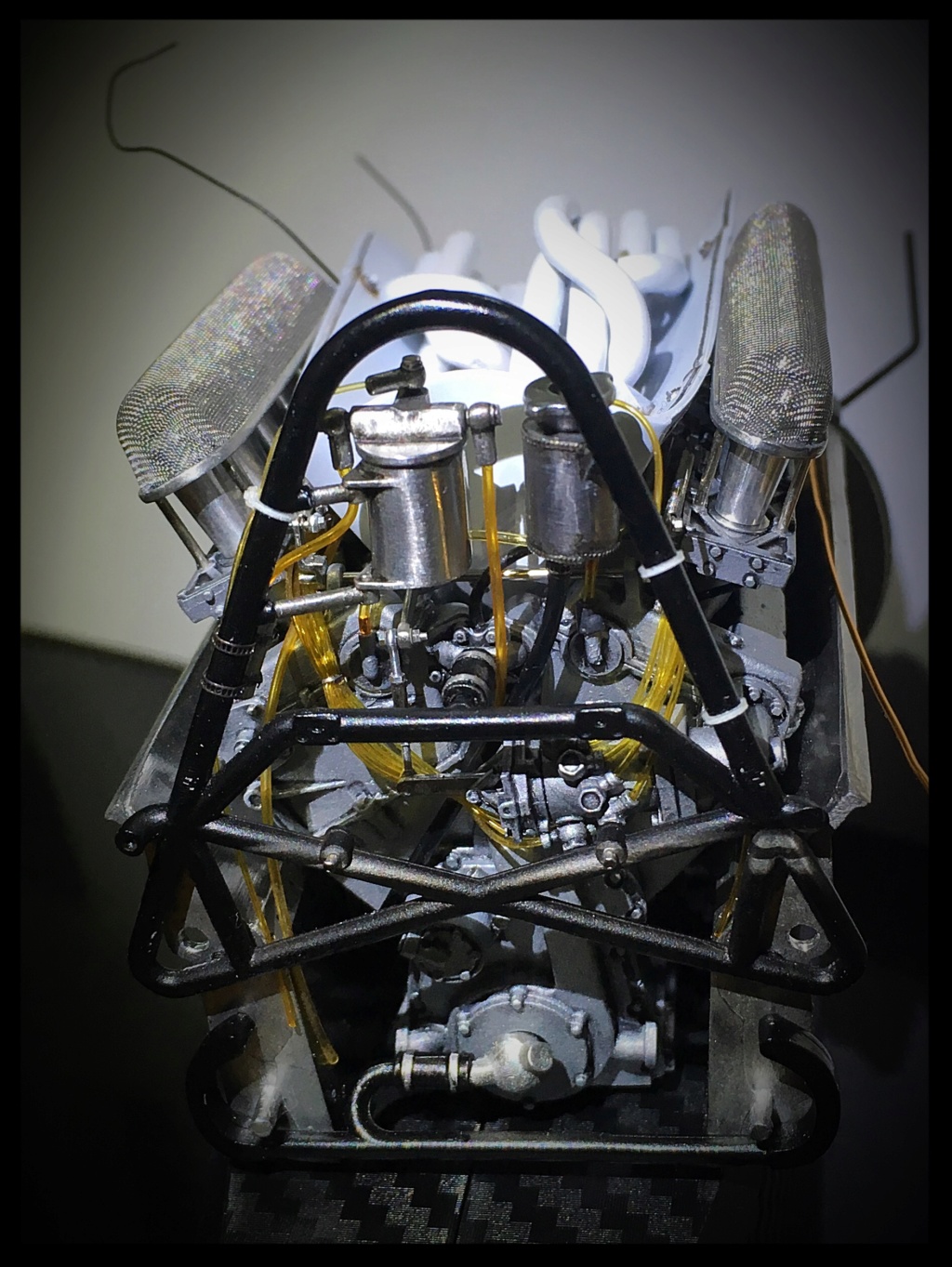

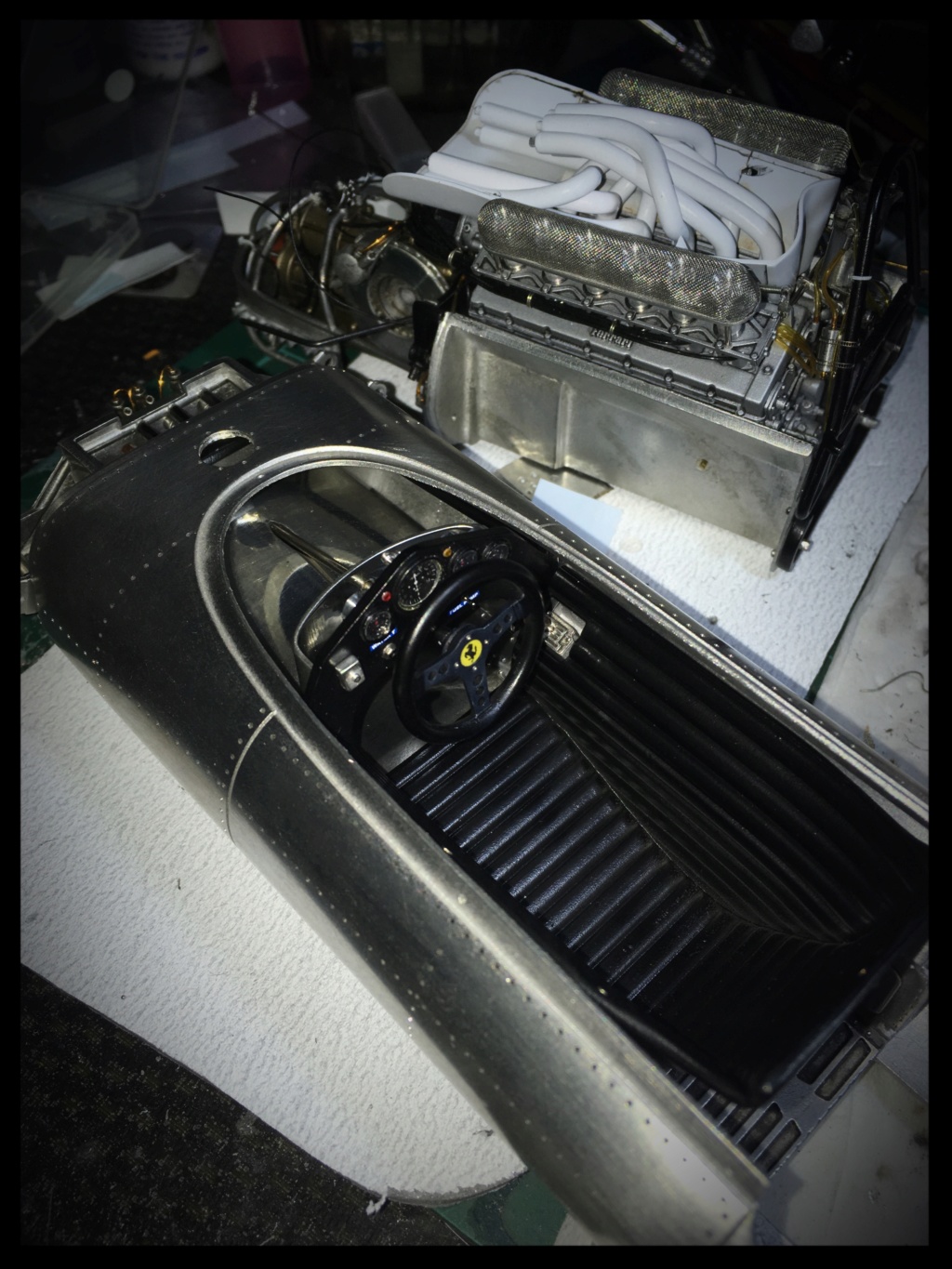

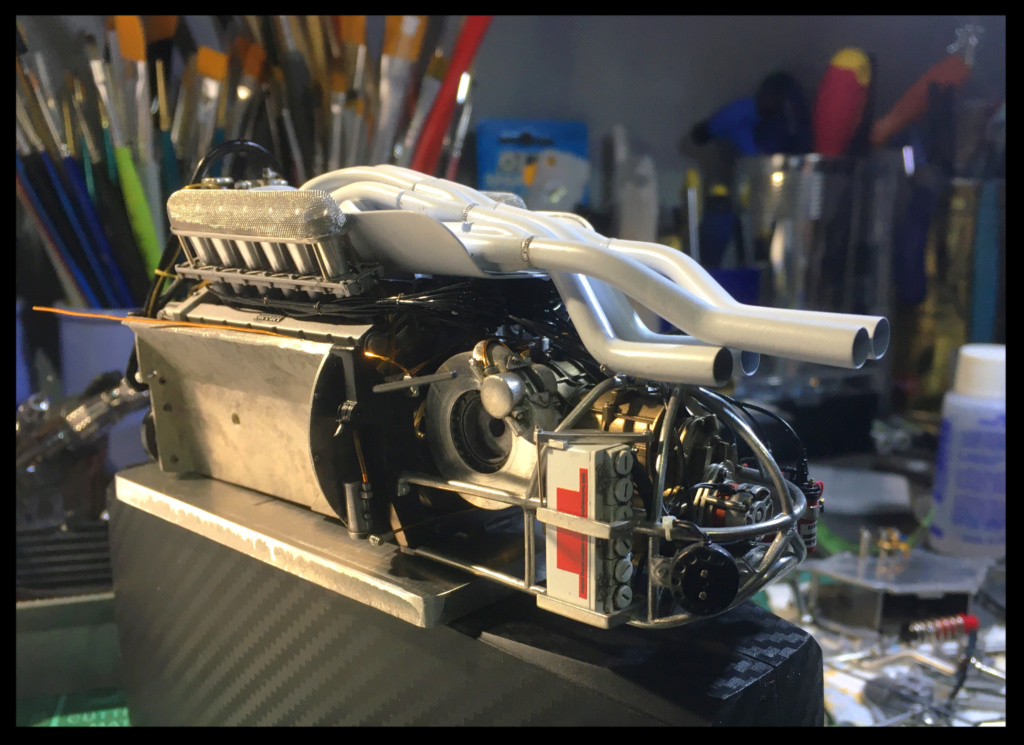

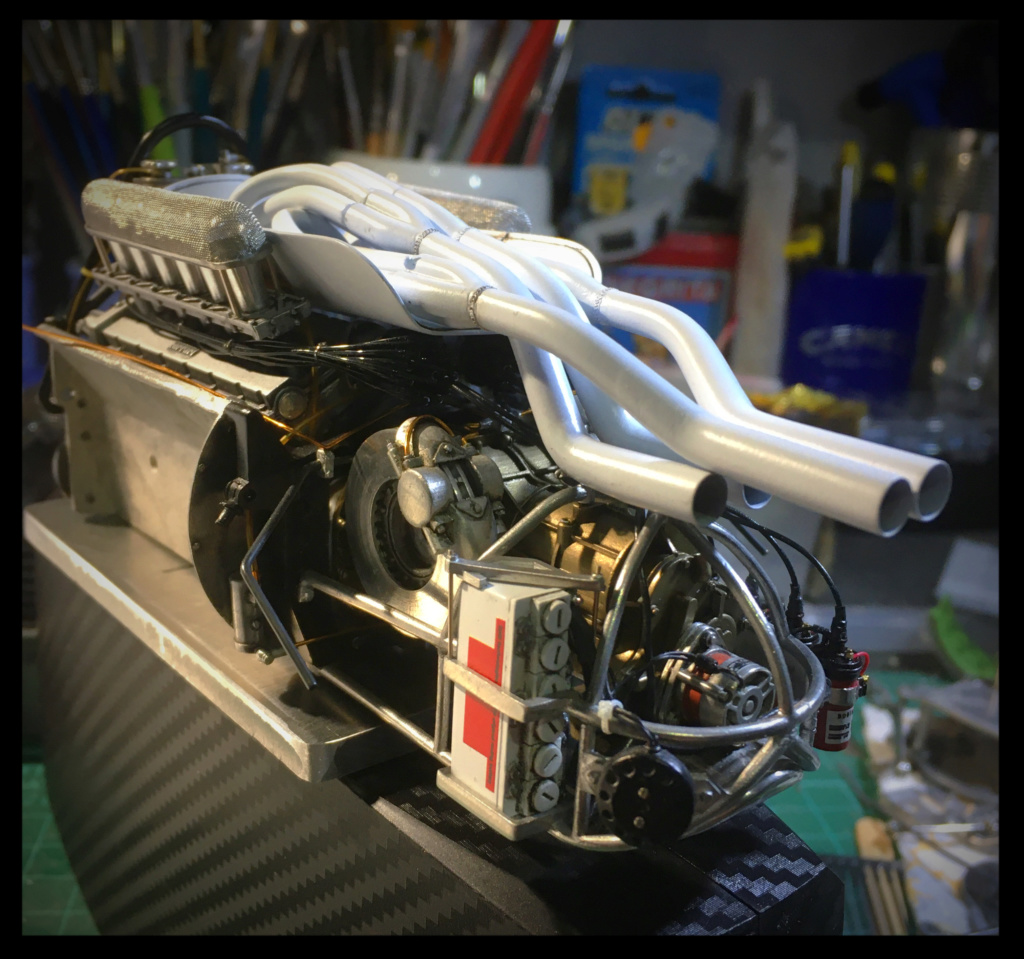

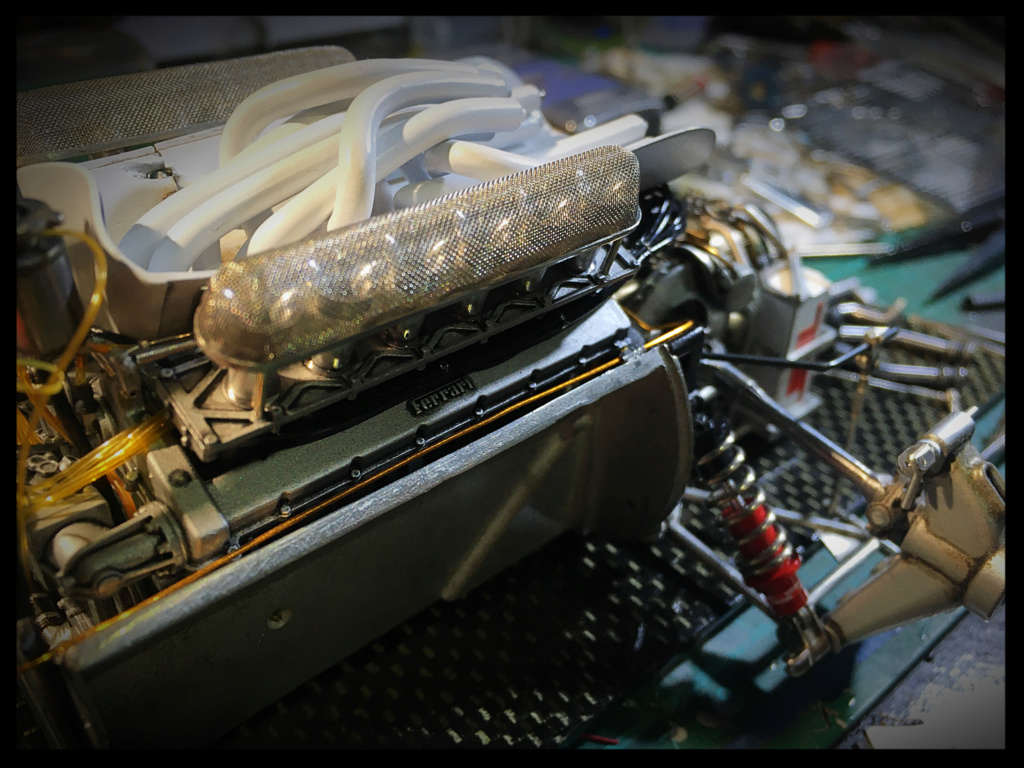

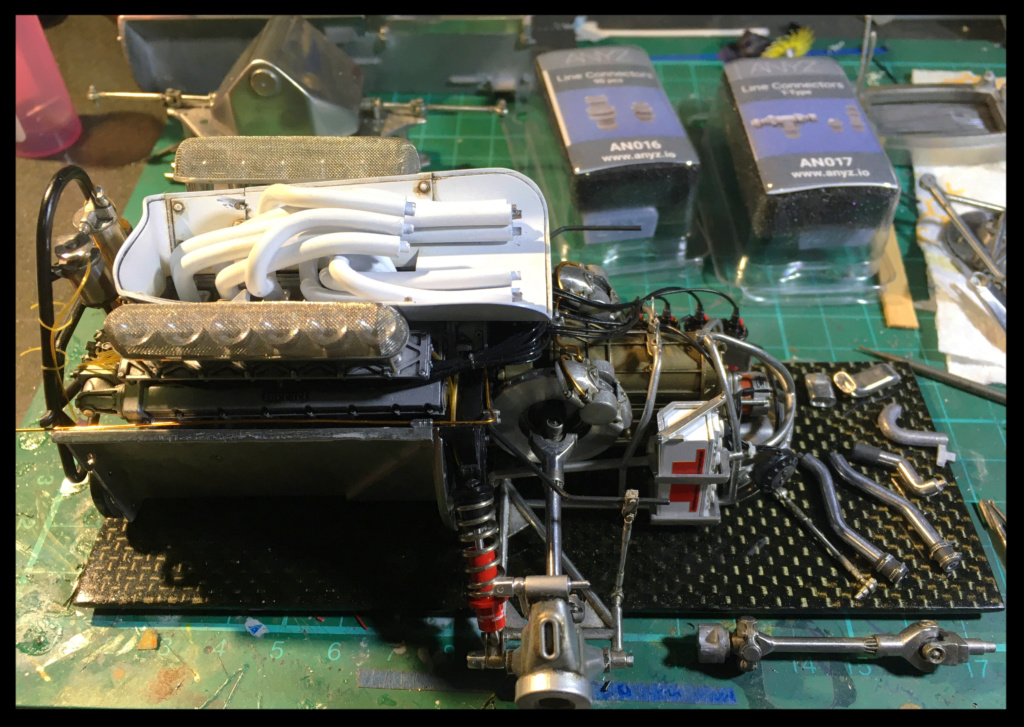

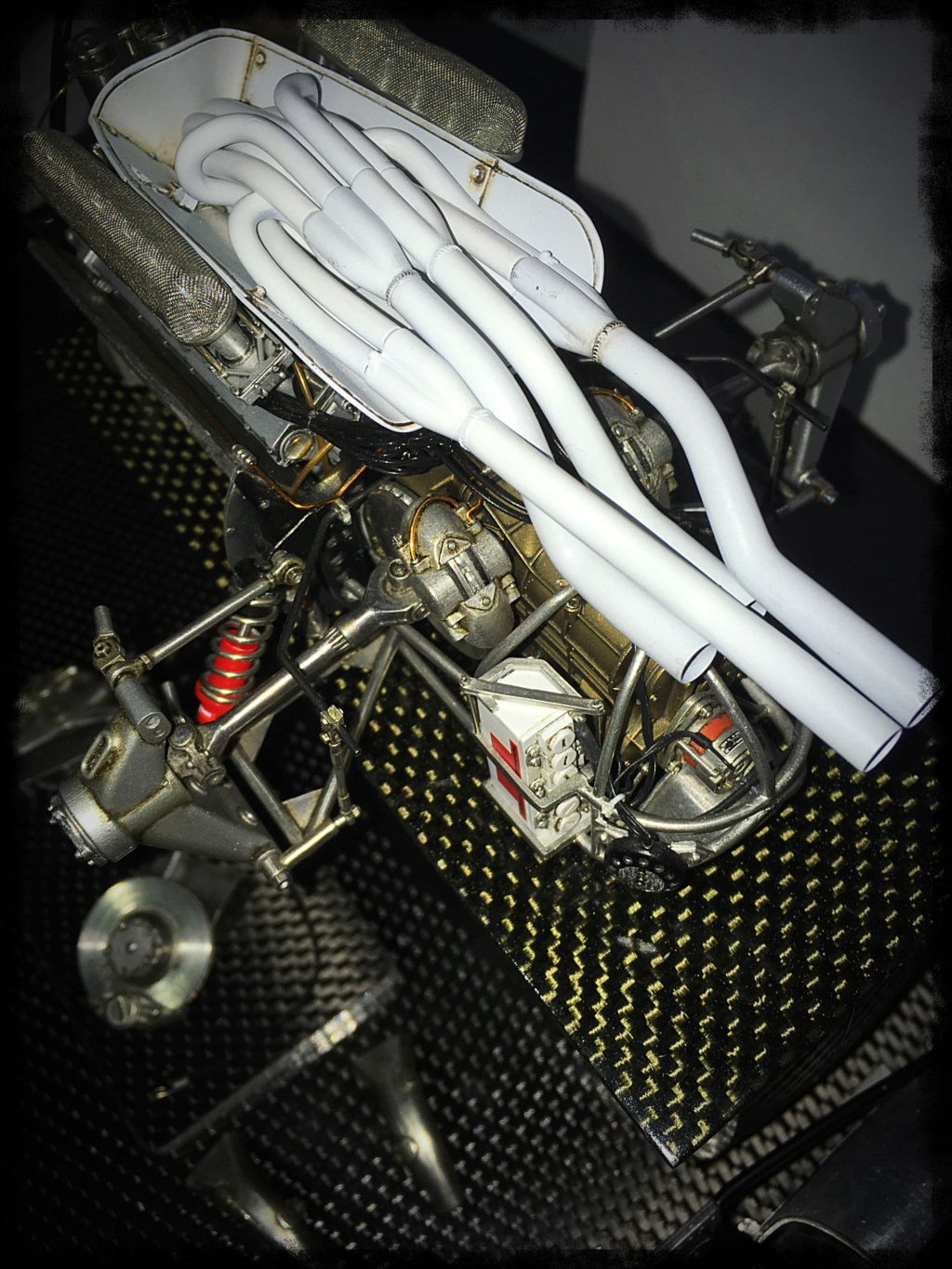

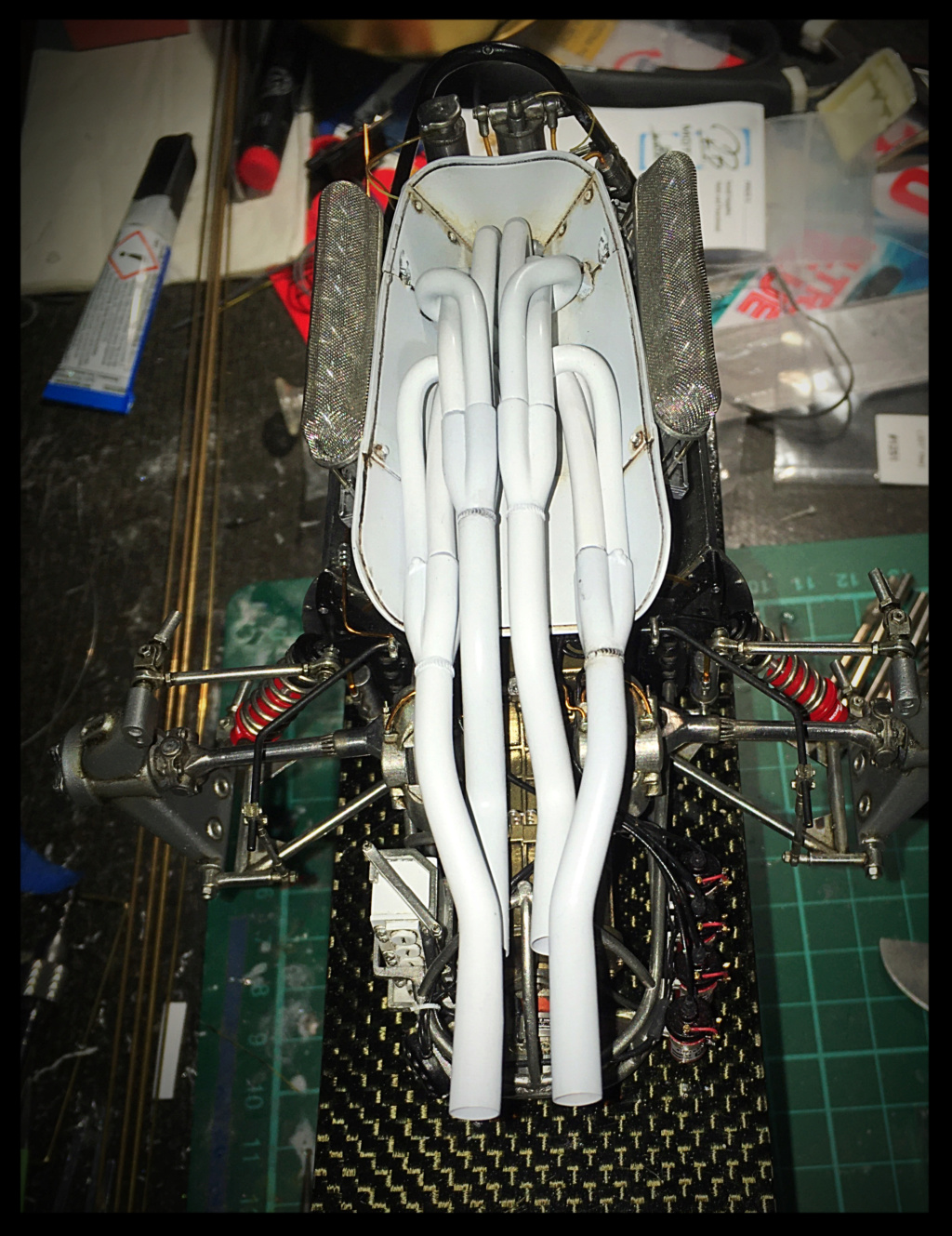

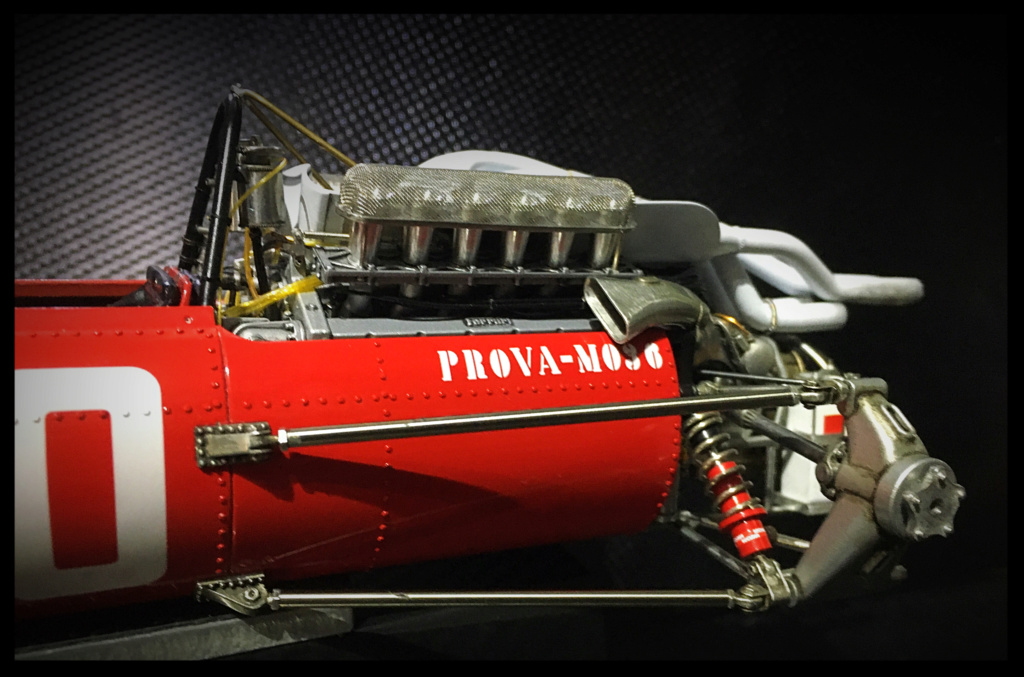

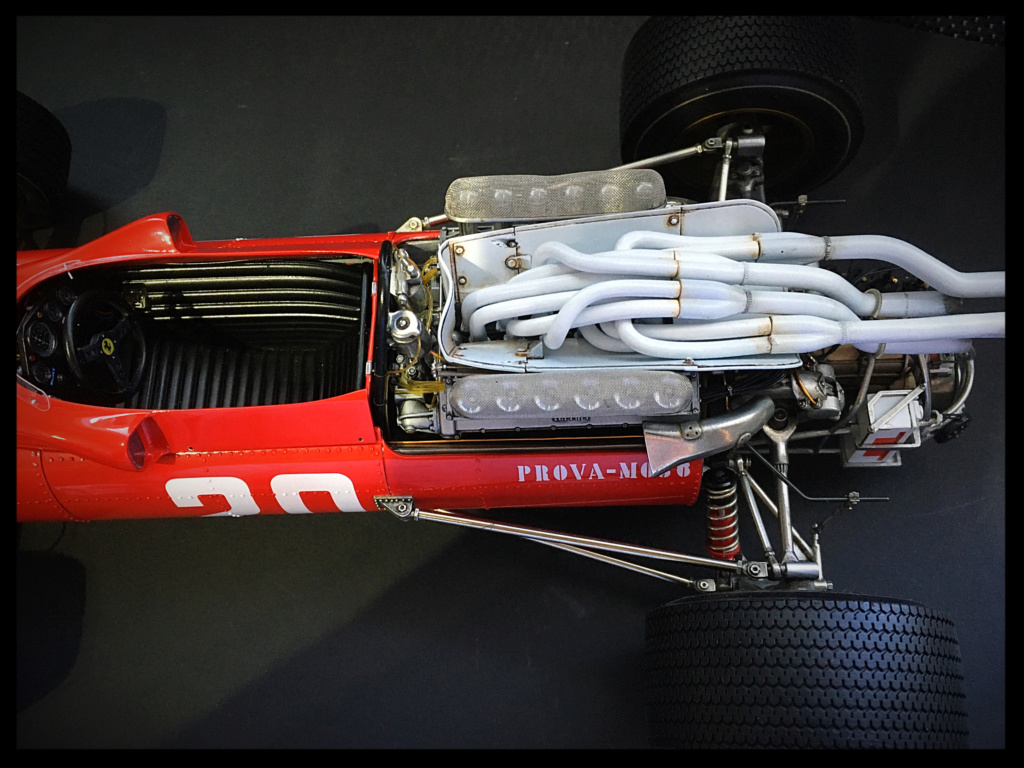

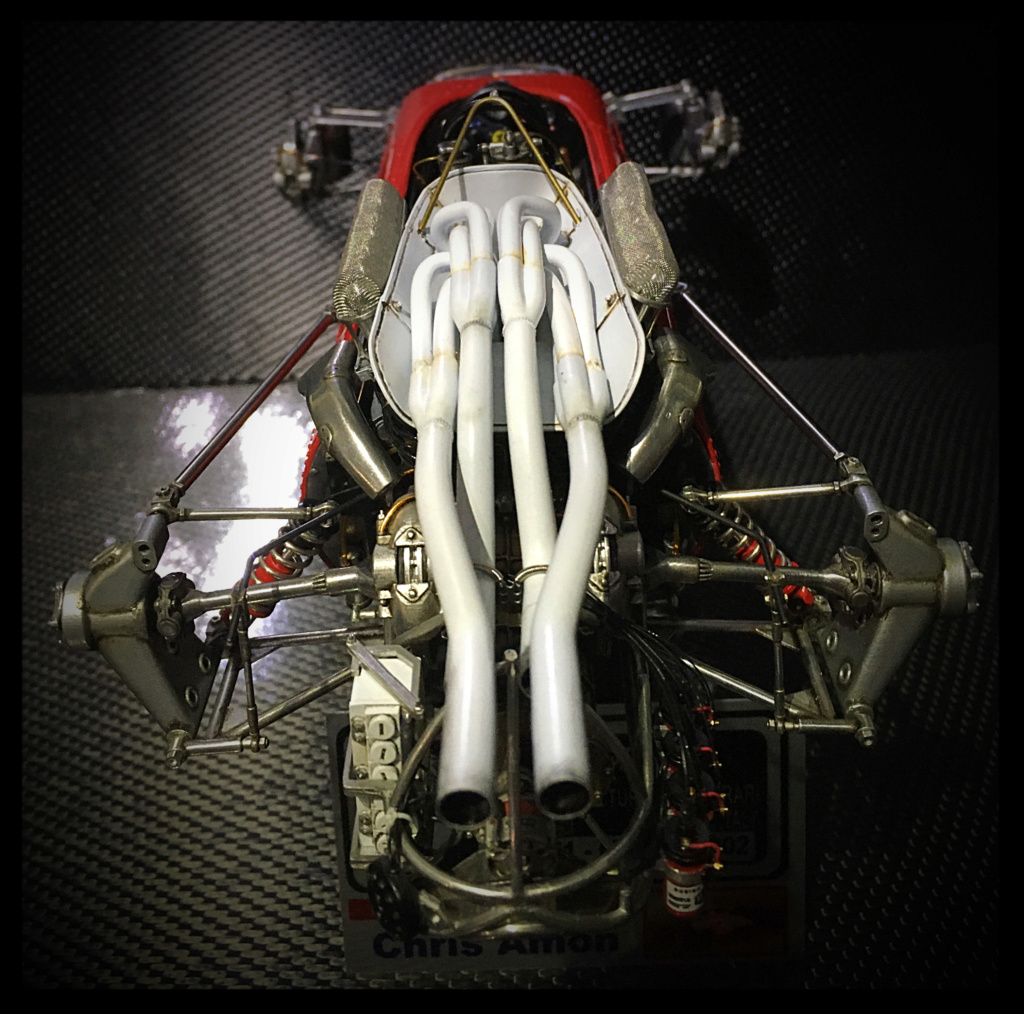

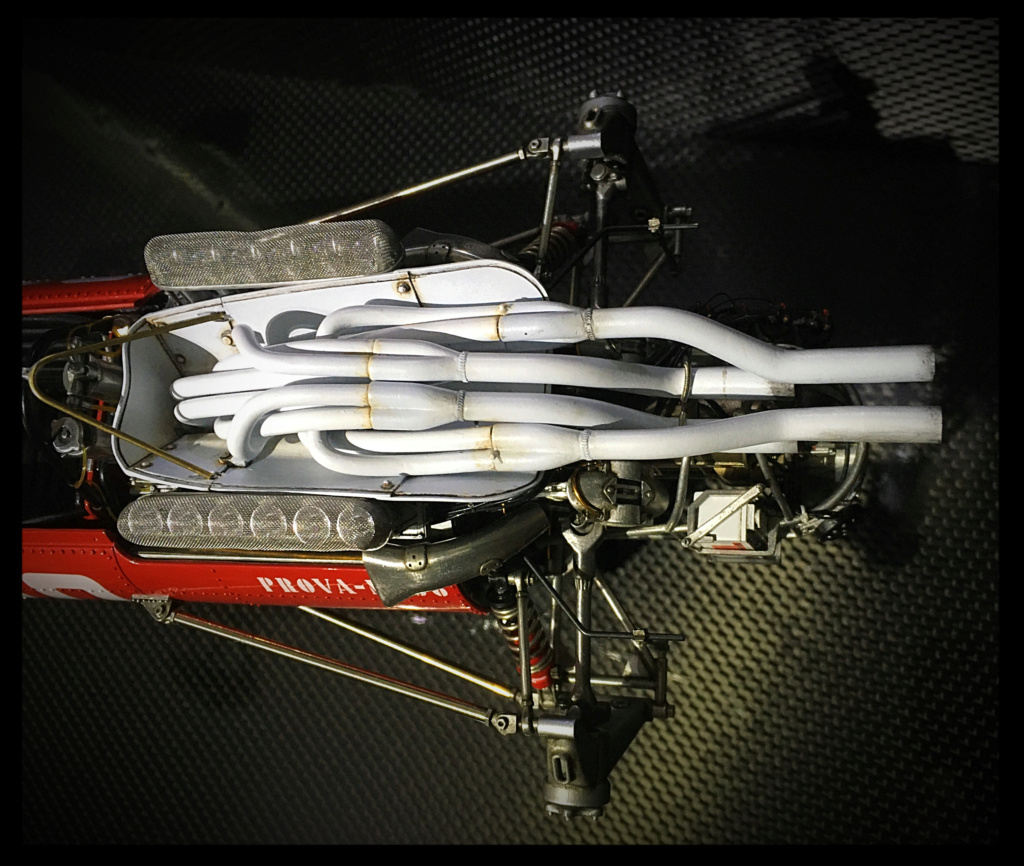

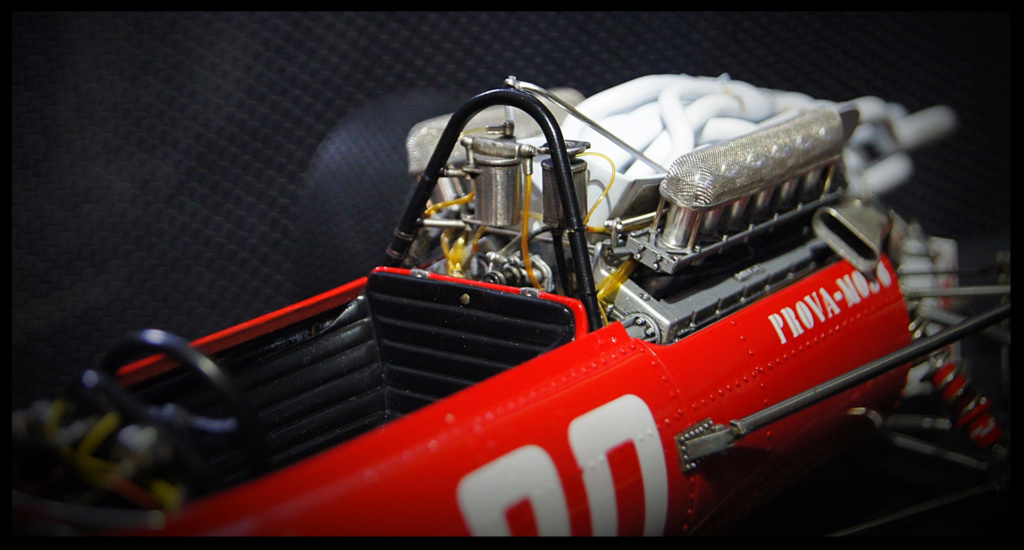

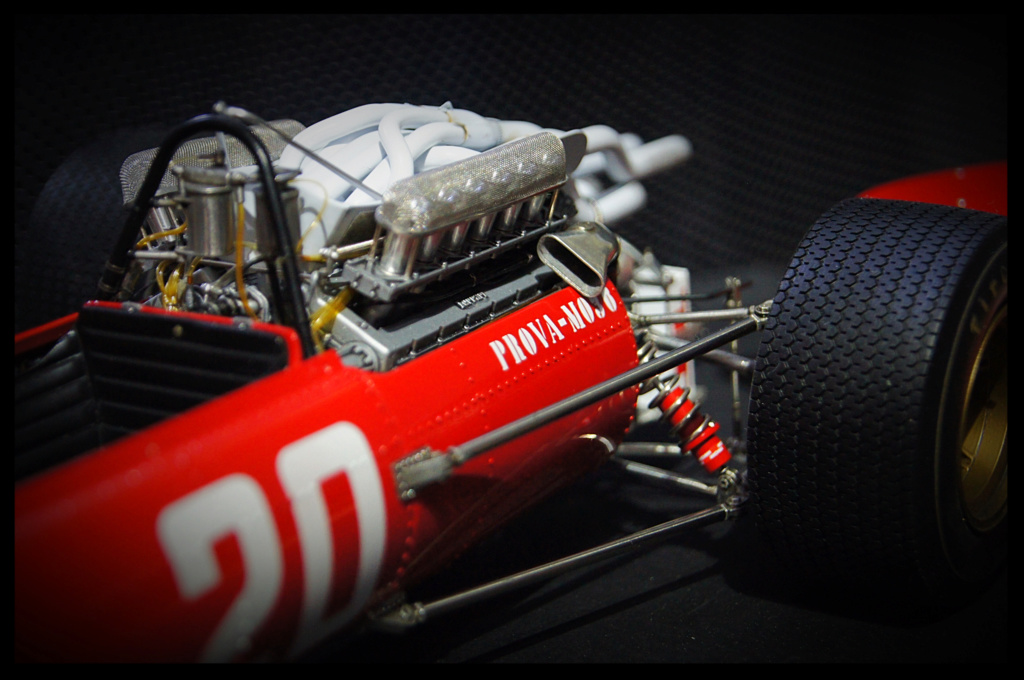

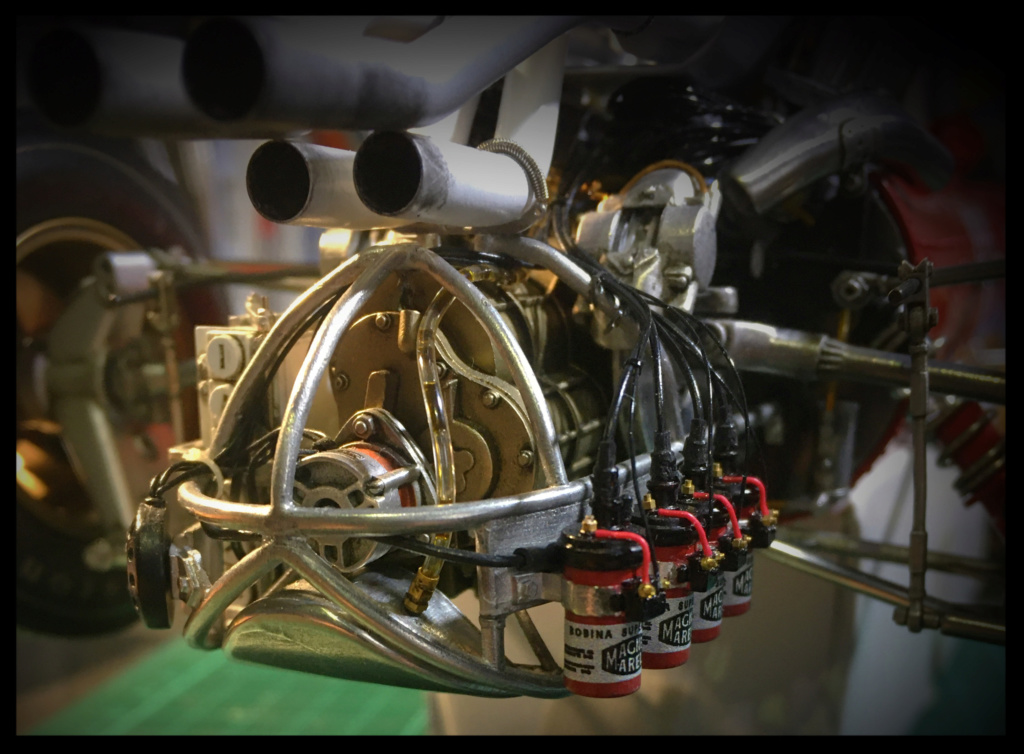

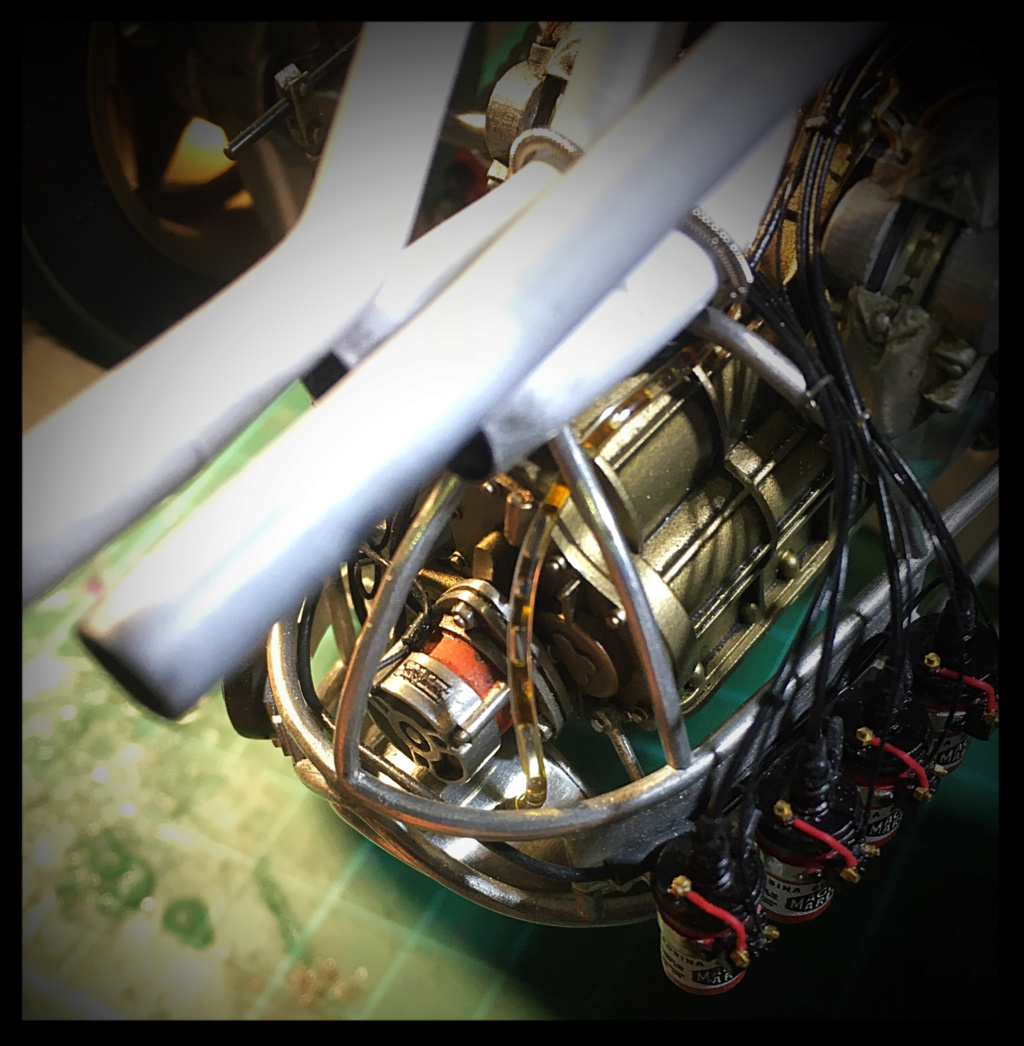

Here are few pics of the engine.

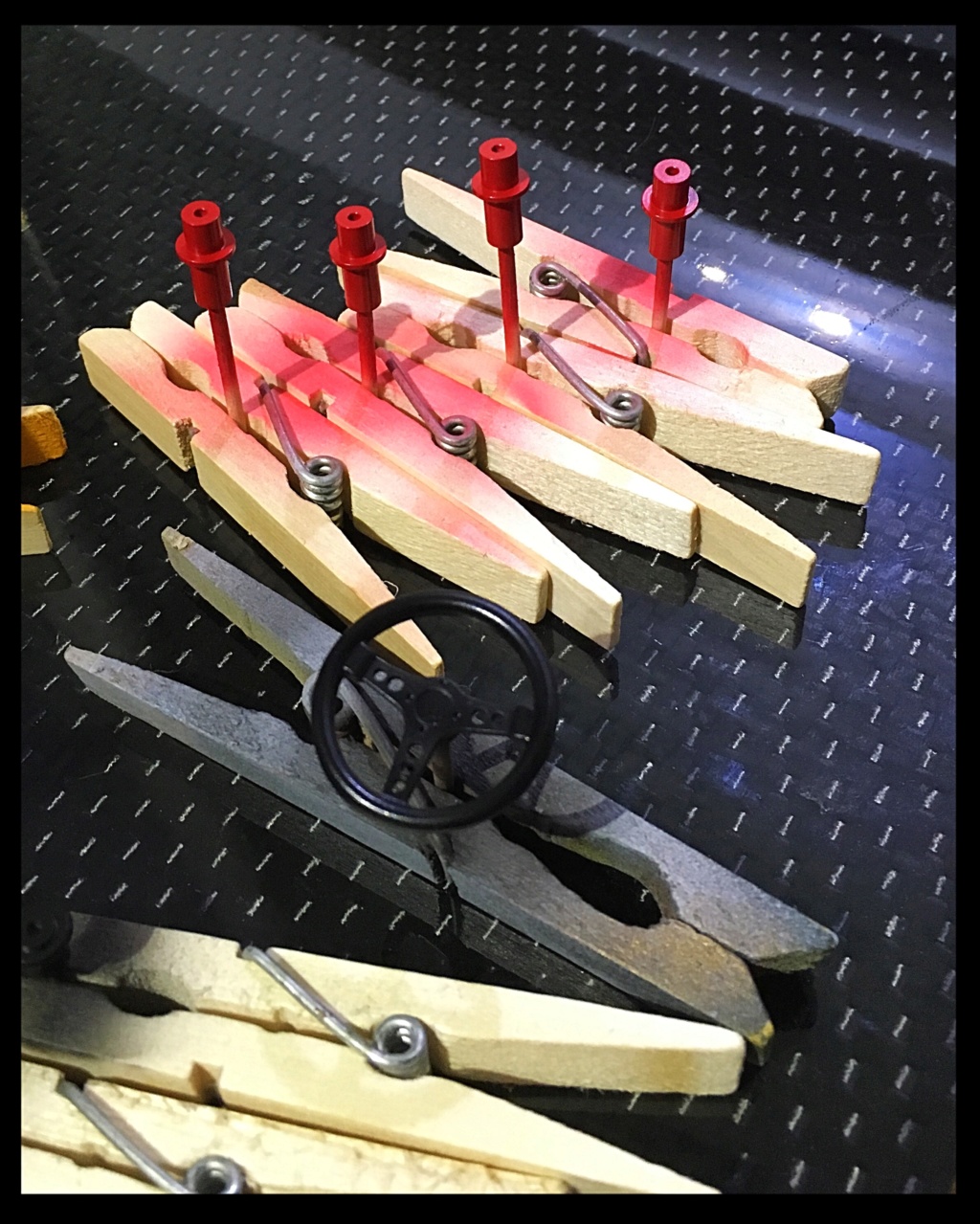

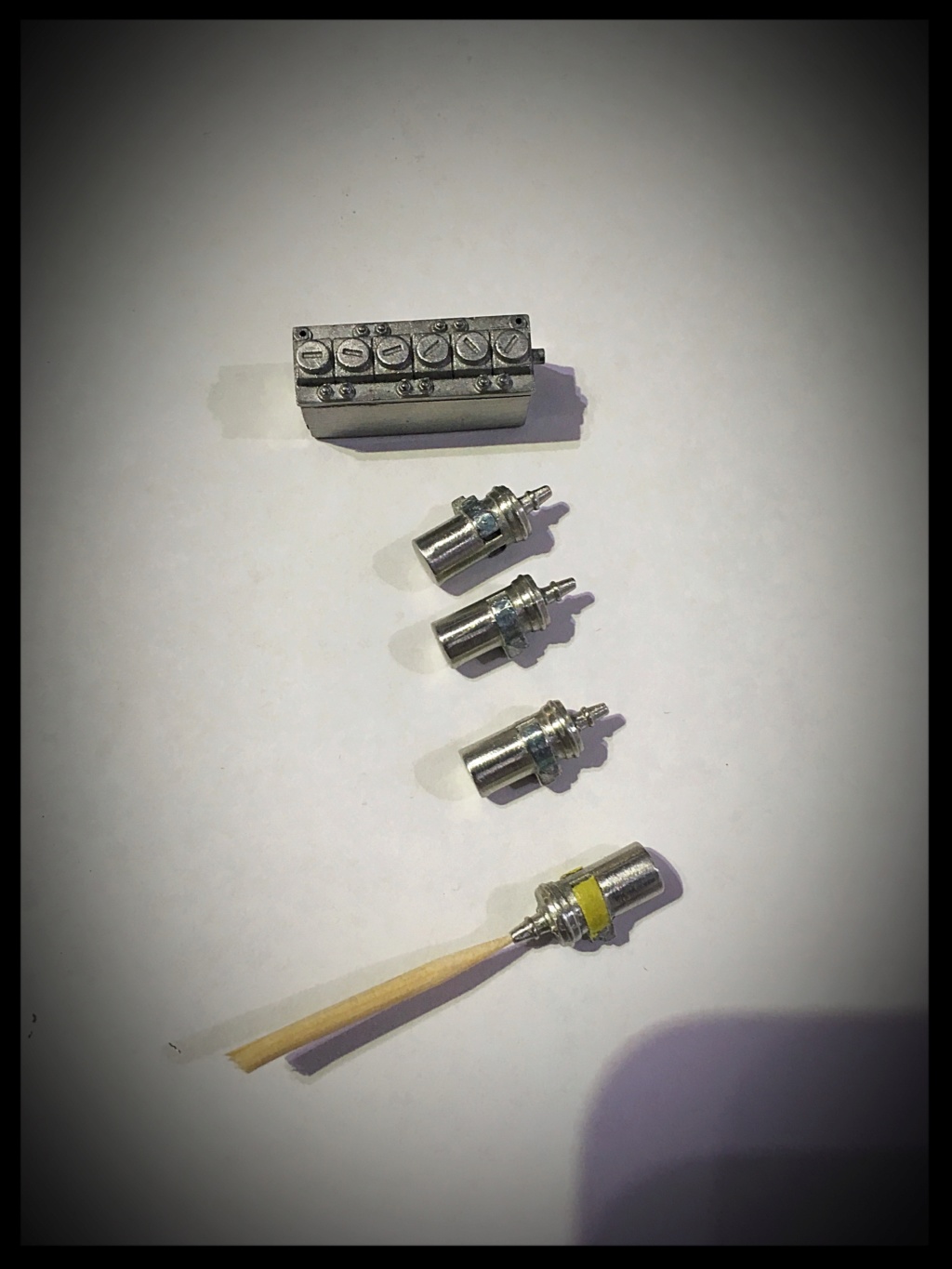

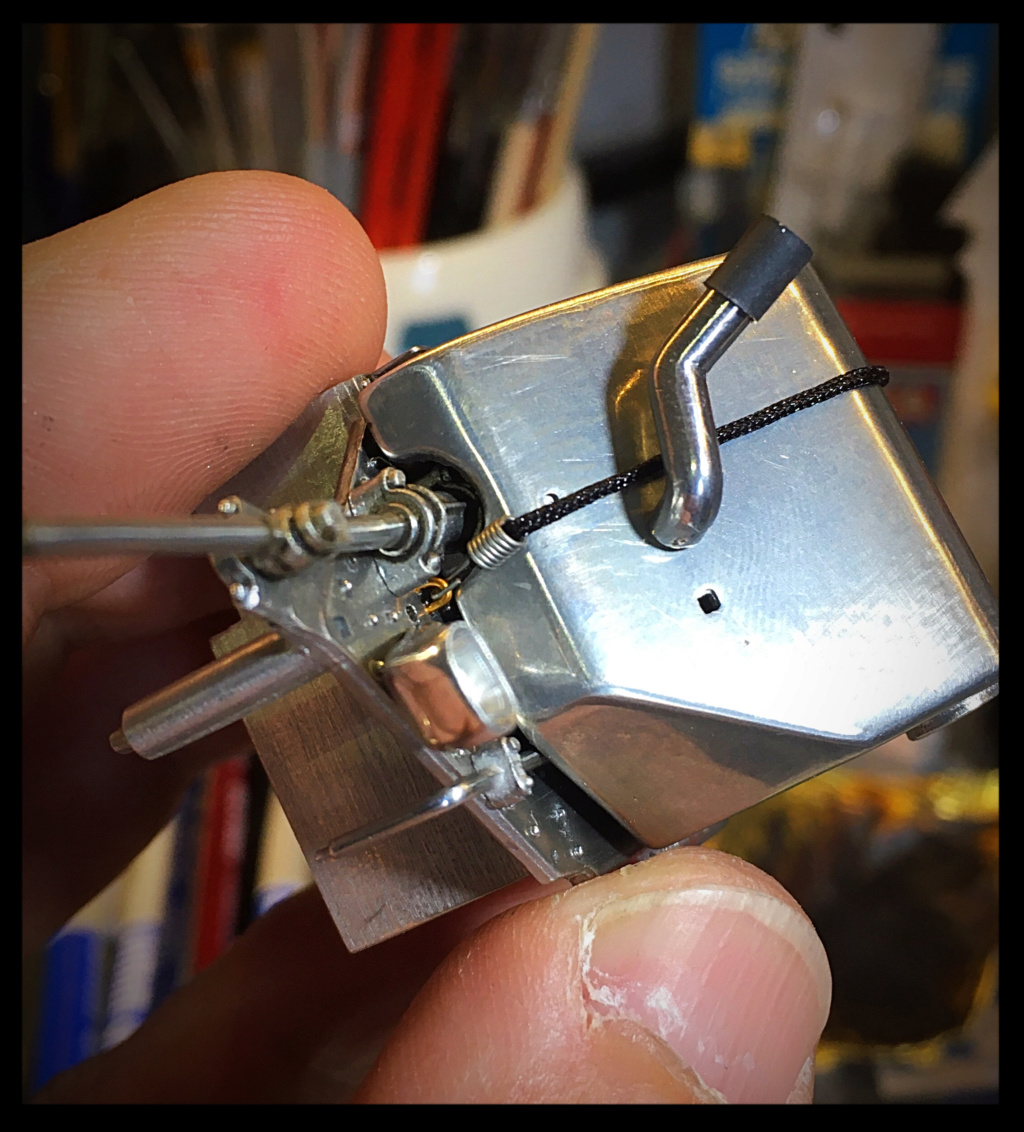

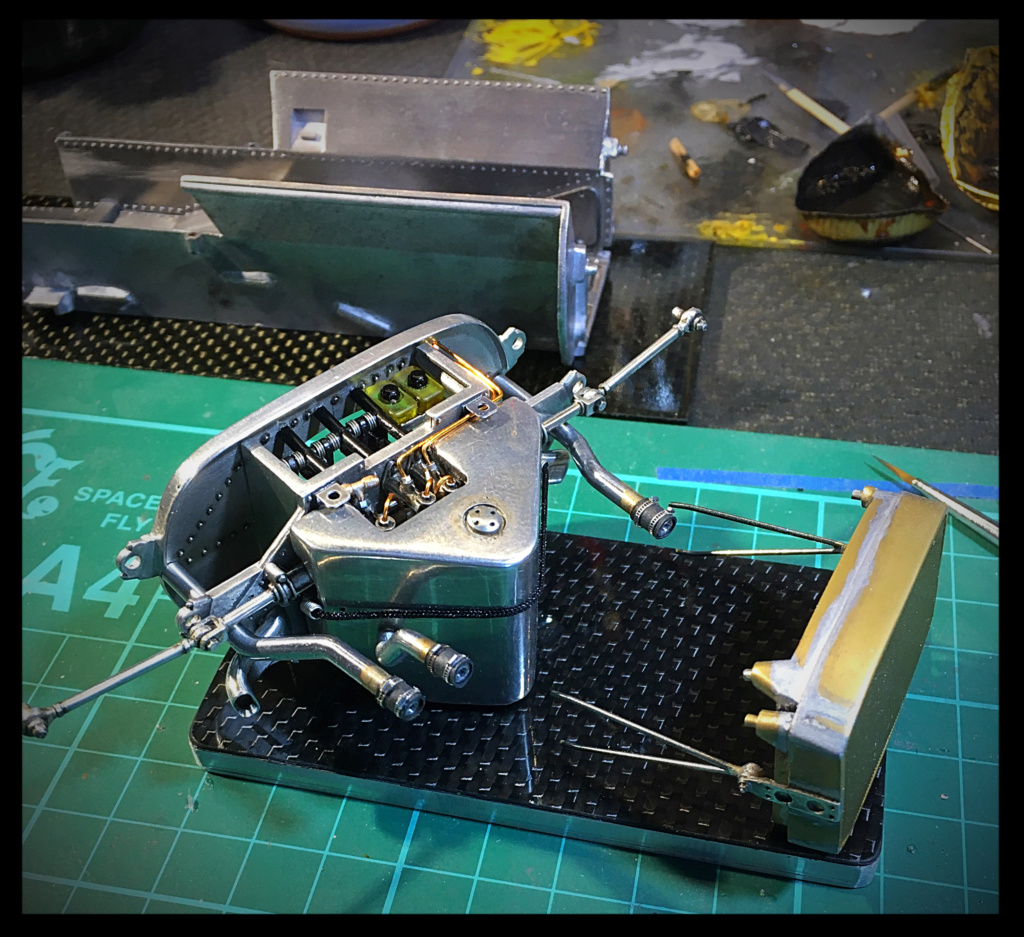

I was not that happy with the kit throttle linkage... So I decided to build new ones with machined parts from RBMotion.

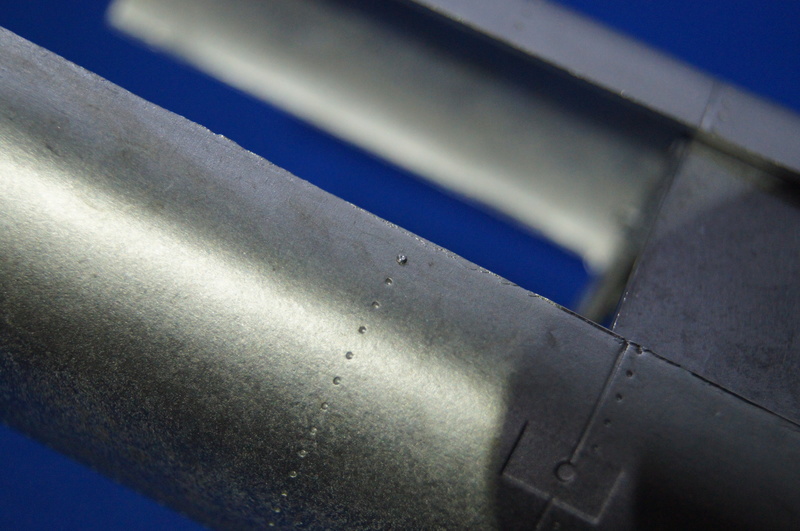

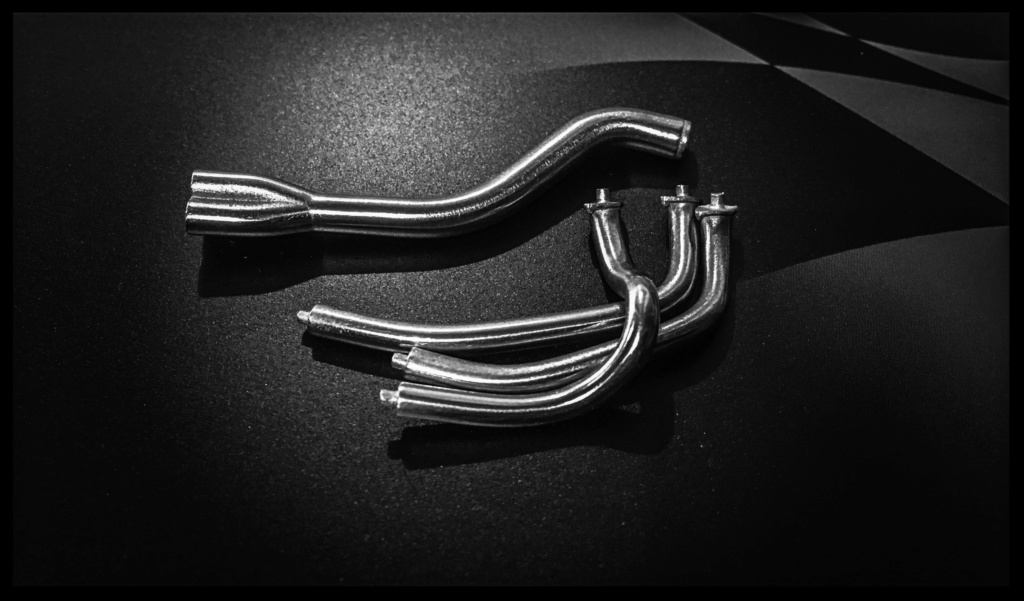

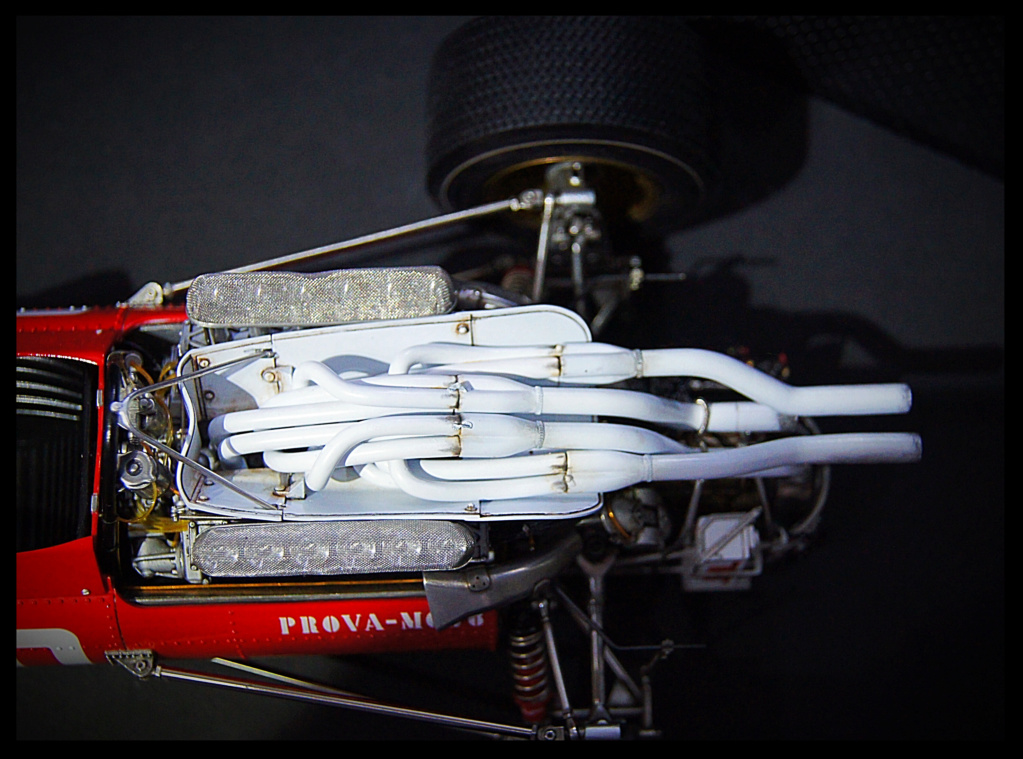

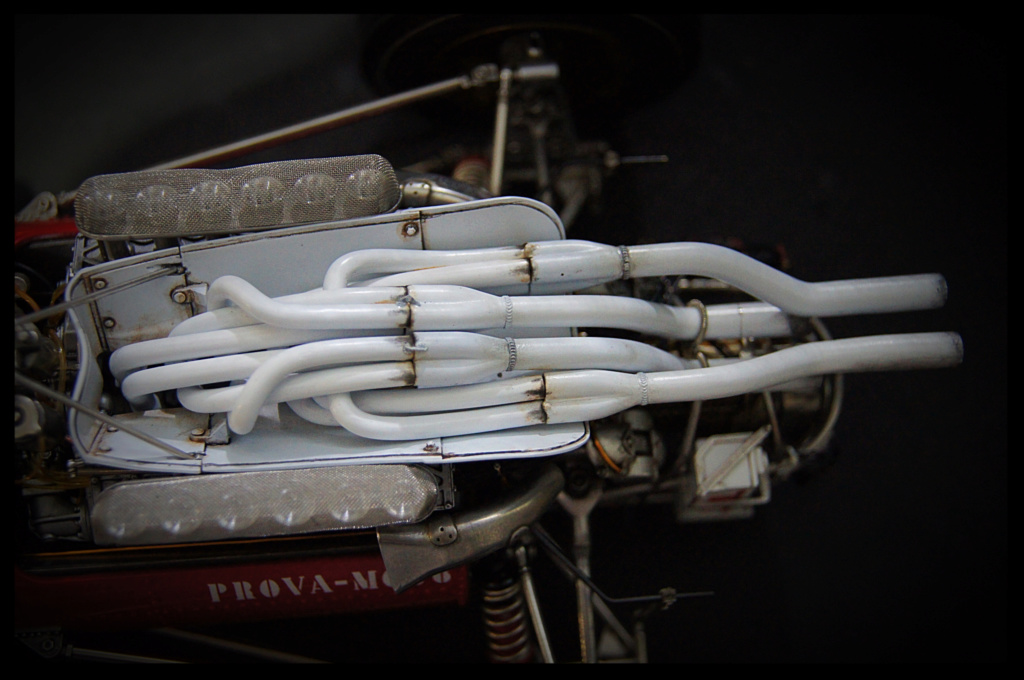

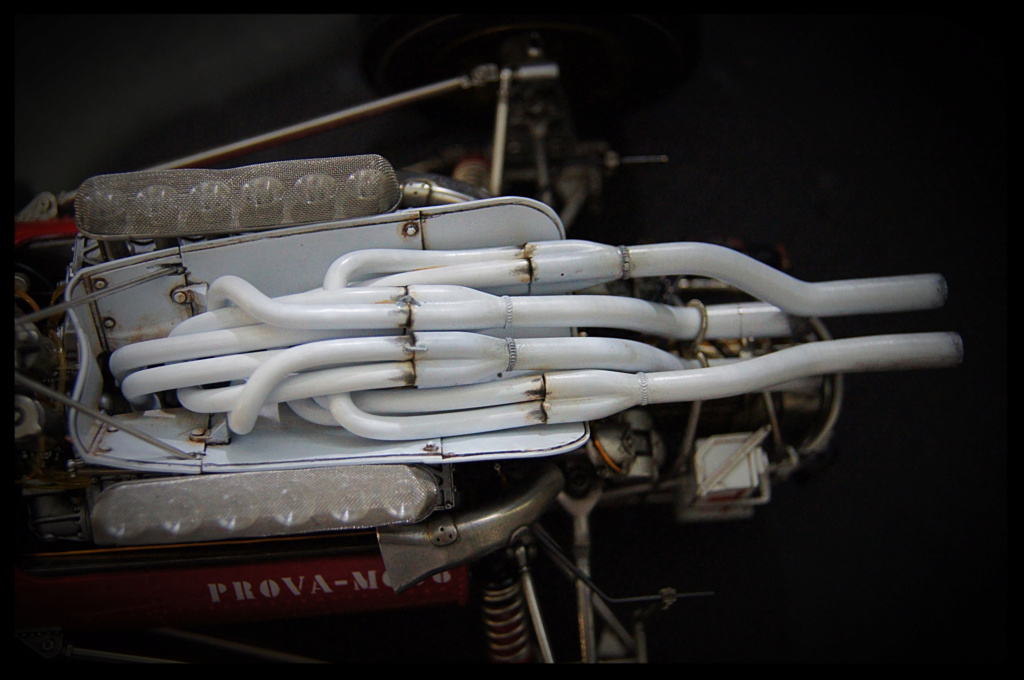

It #65279;was also necessary to show a bit of interest regarding the exhaust and prepare the white metal parts of the Spaghetti:

To prime and paint them:

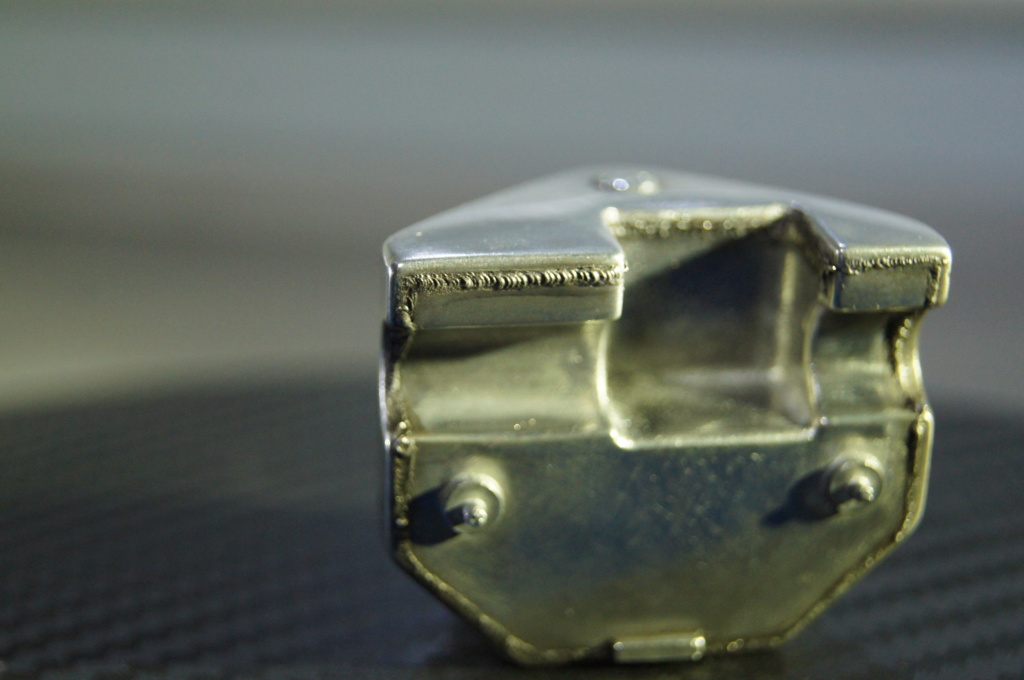

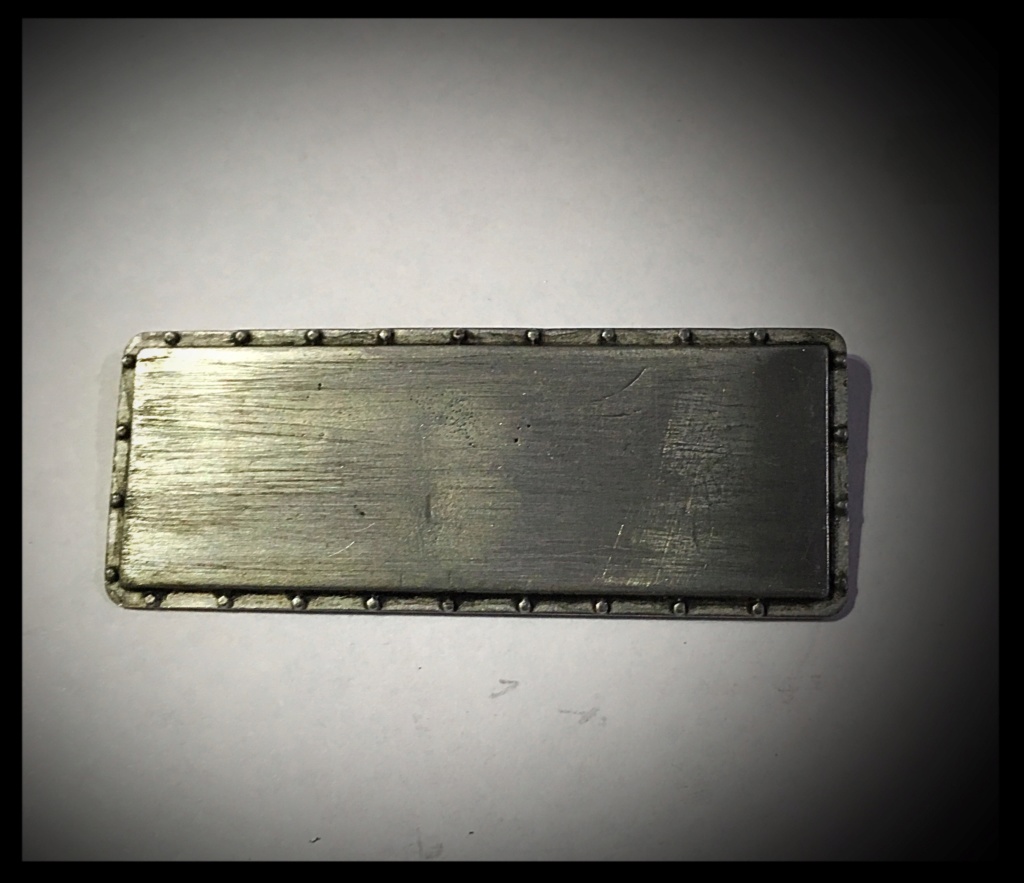

Other parts are just treated to be left with a natural metal finish:

I prefer to solder them instead of gluing for evident reasons:

I played a bit with the iron in order to replicate weld seams :

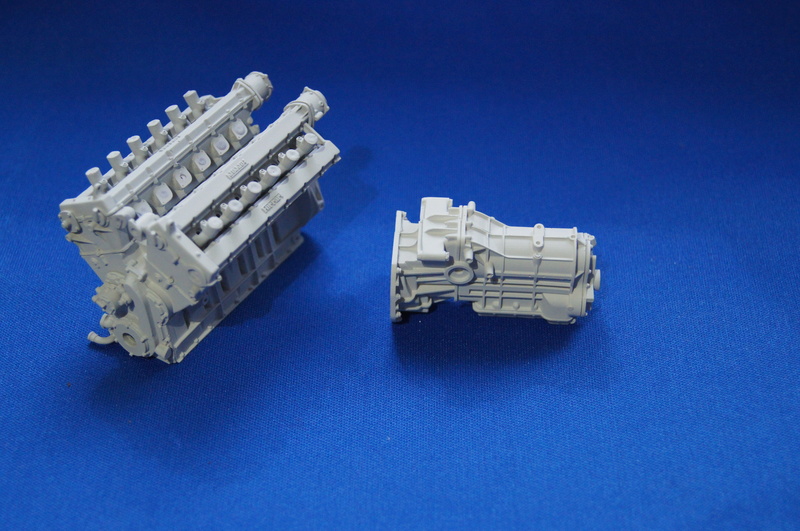

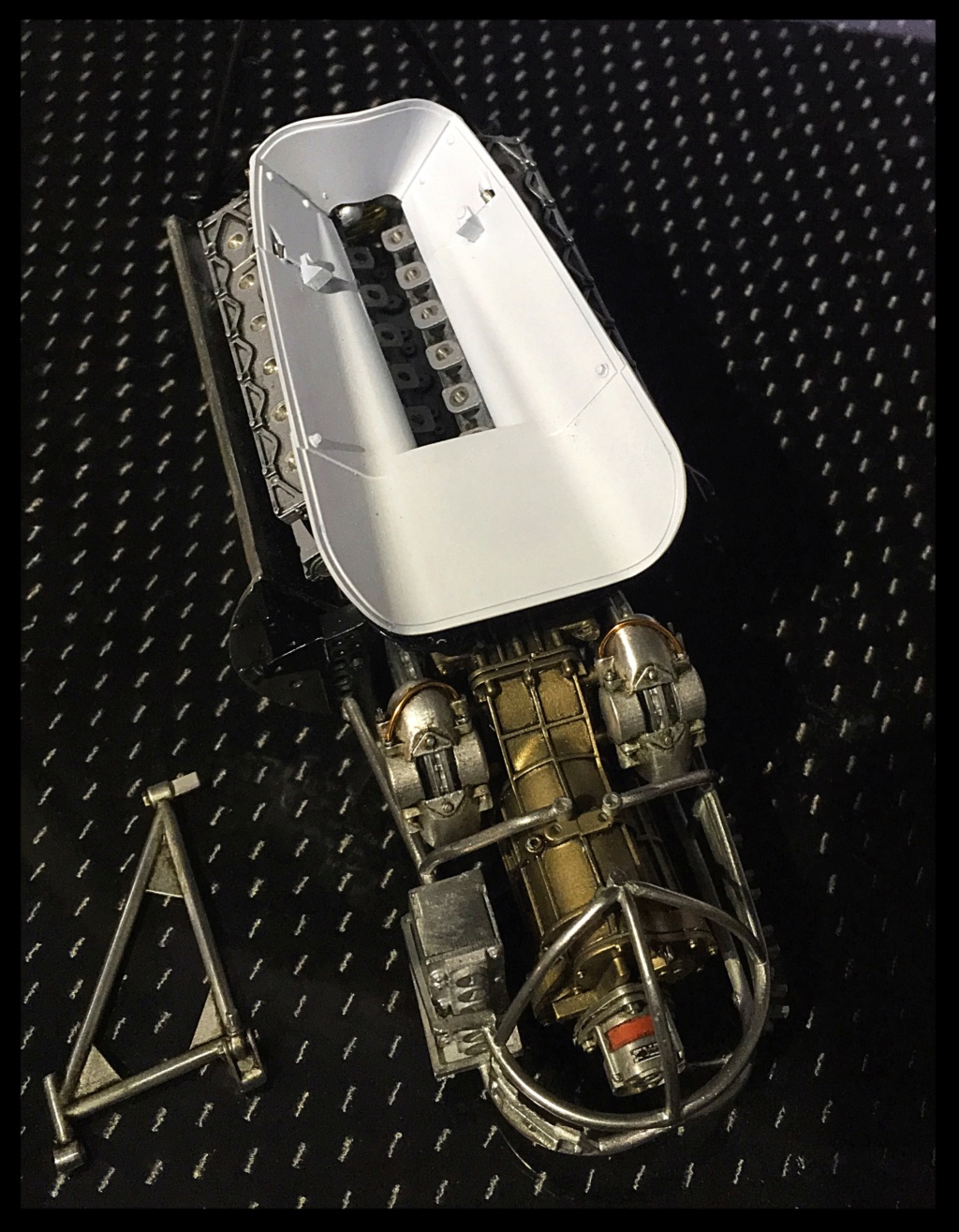

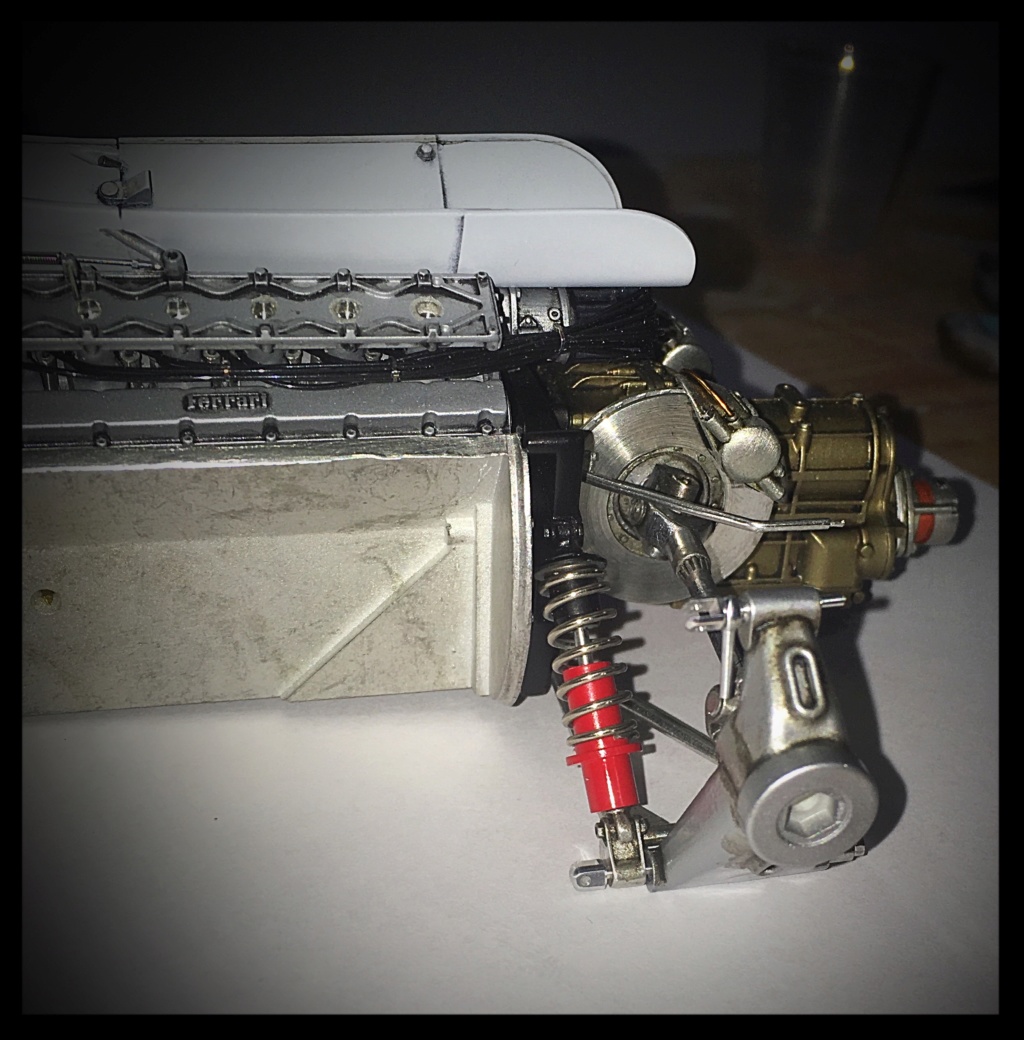

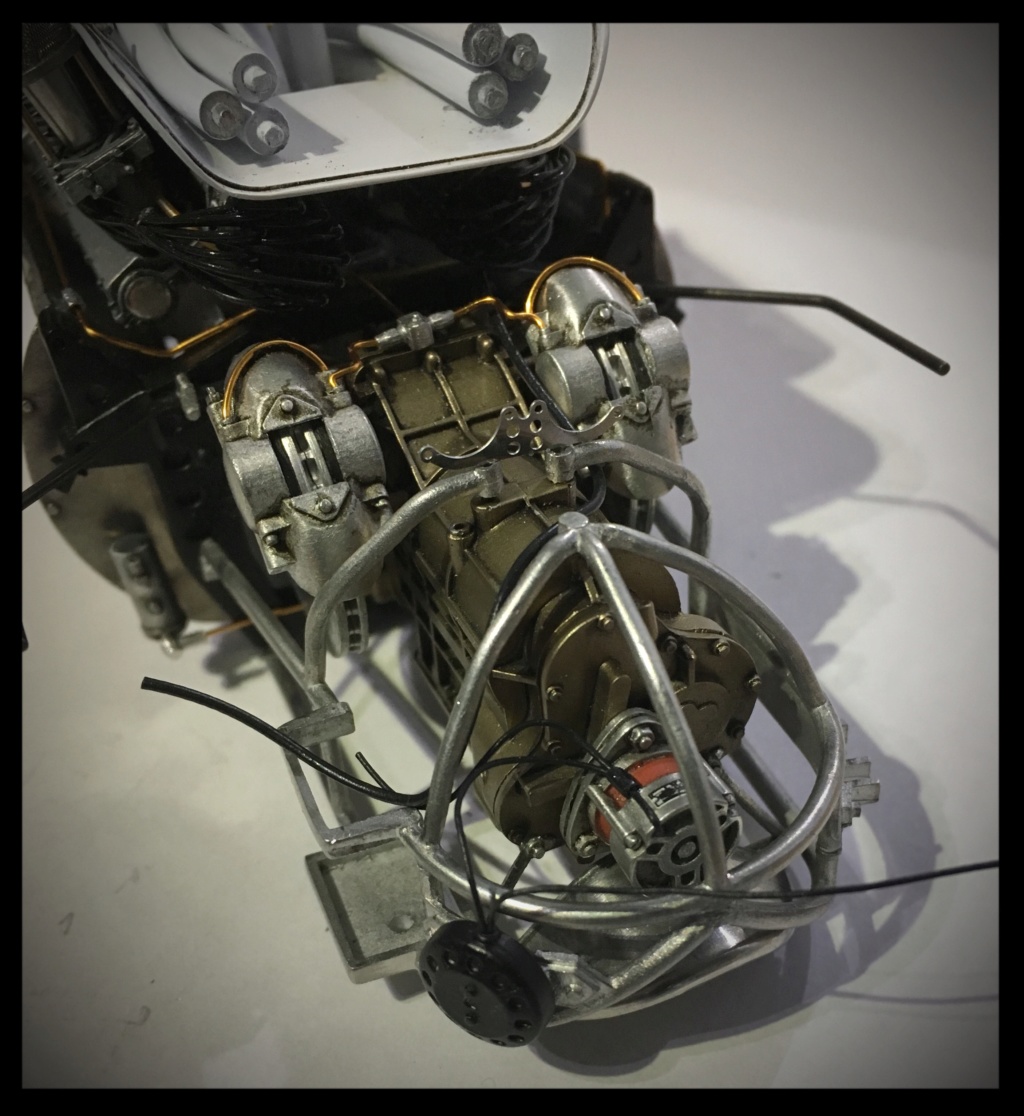

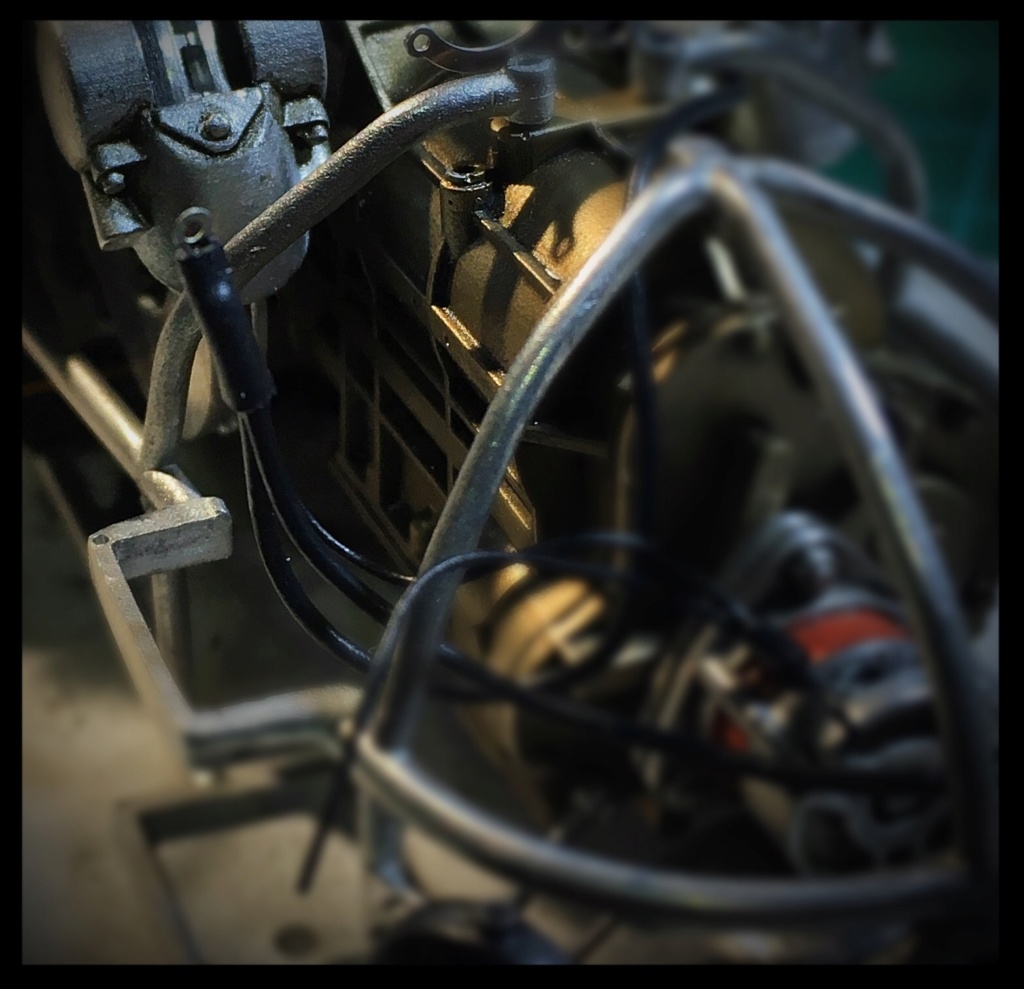

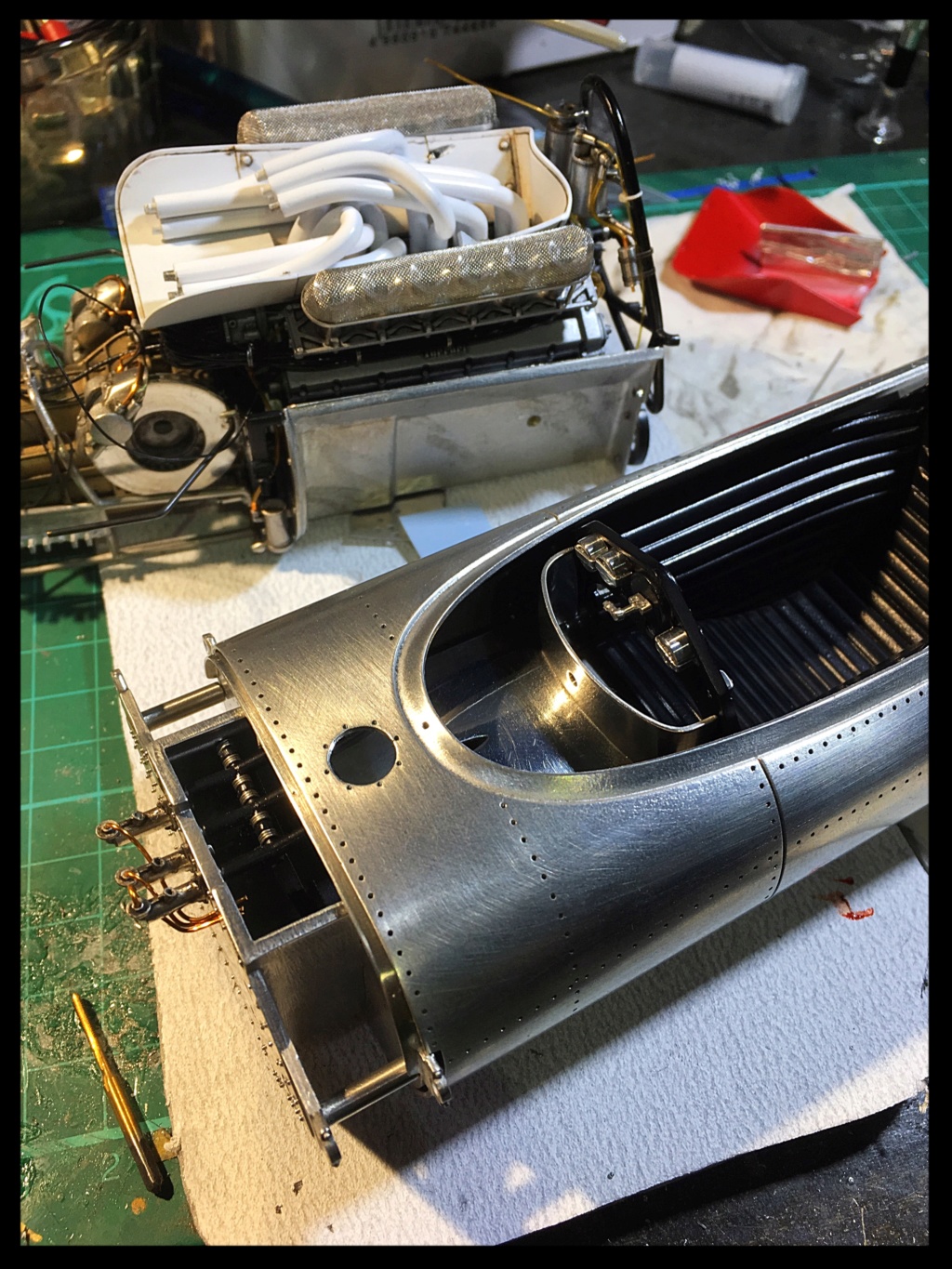

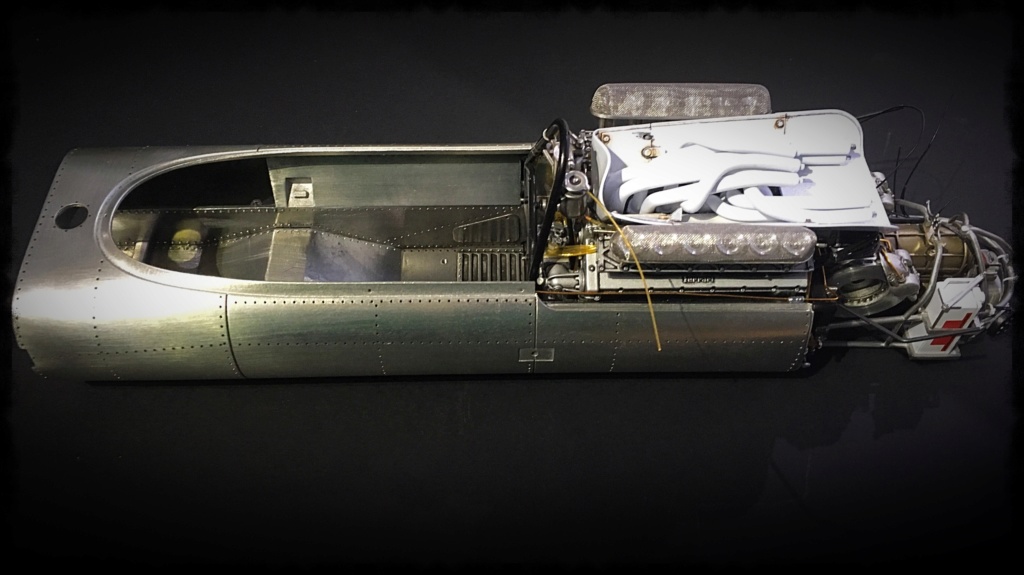

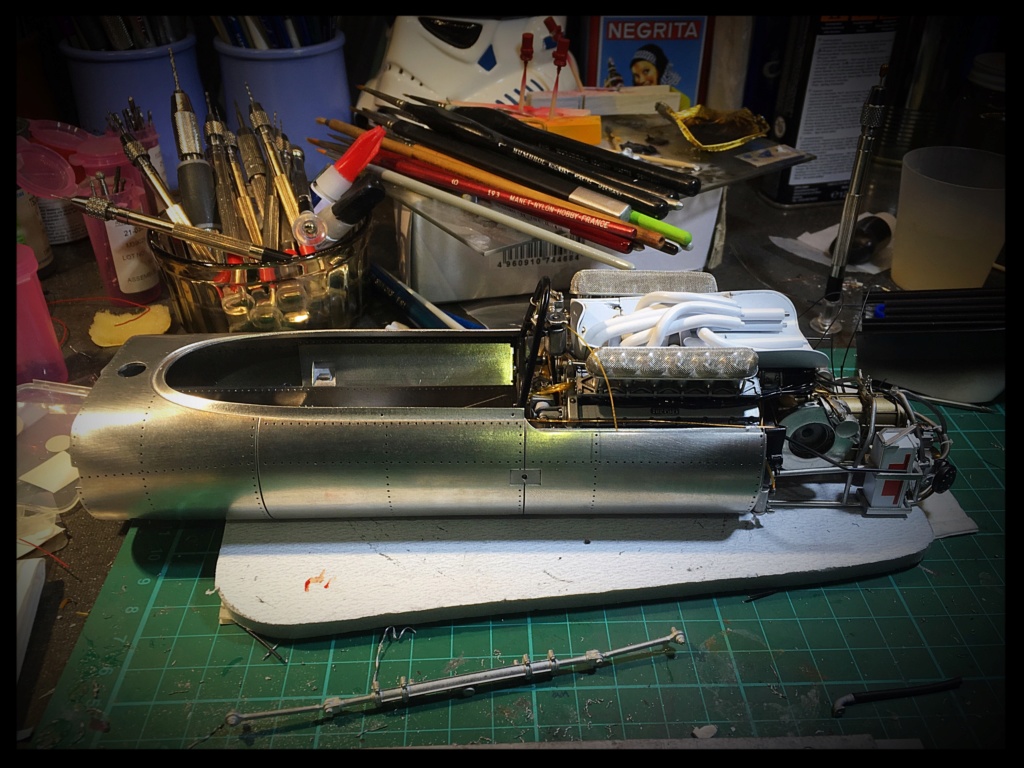

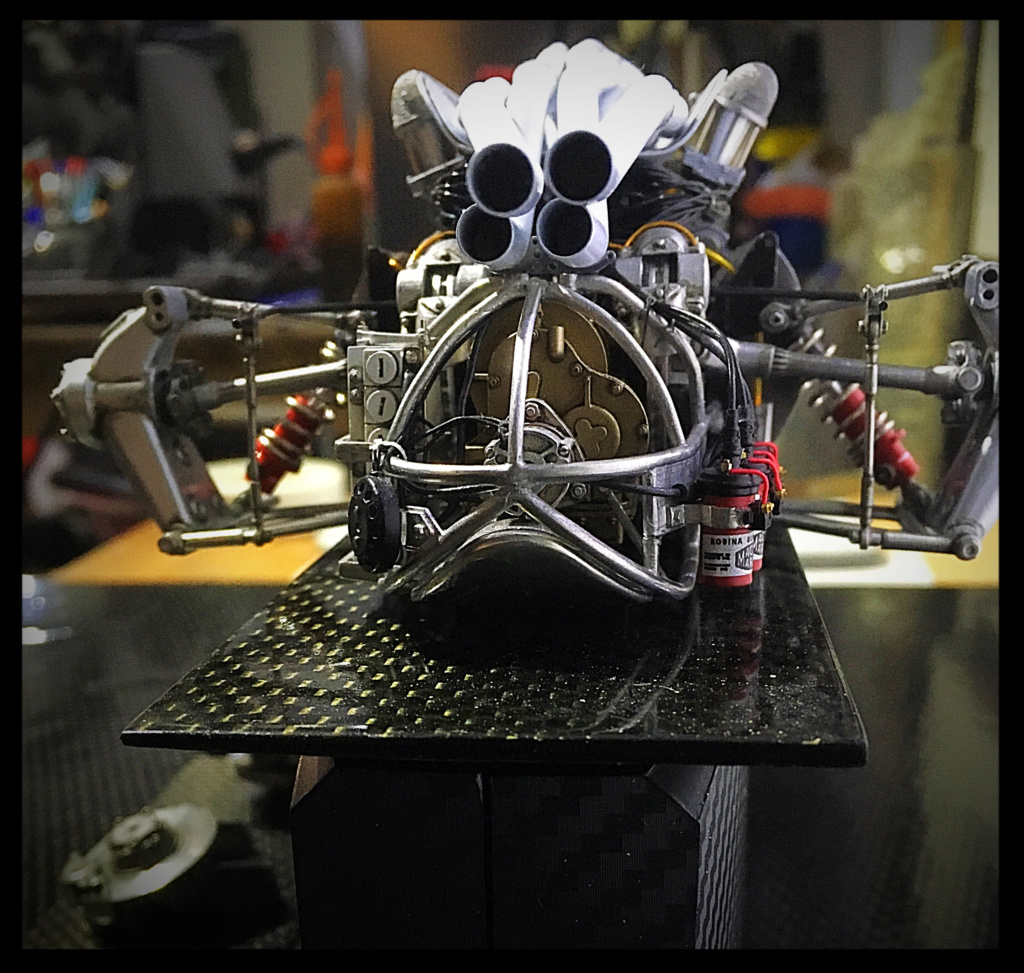

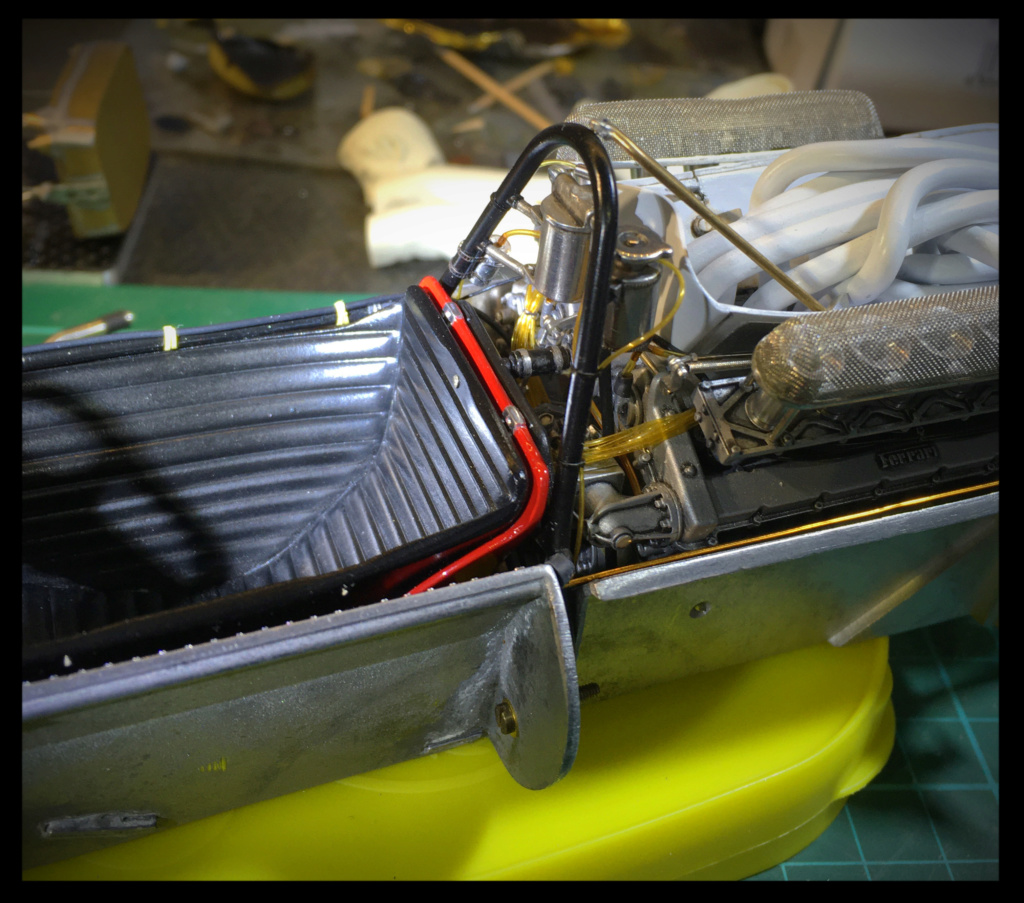

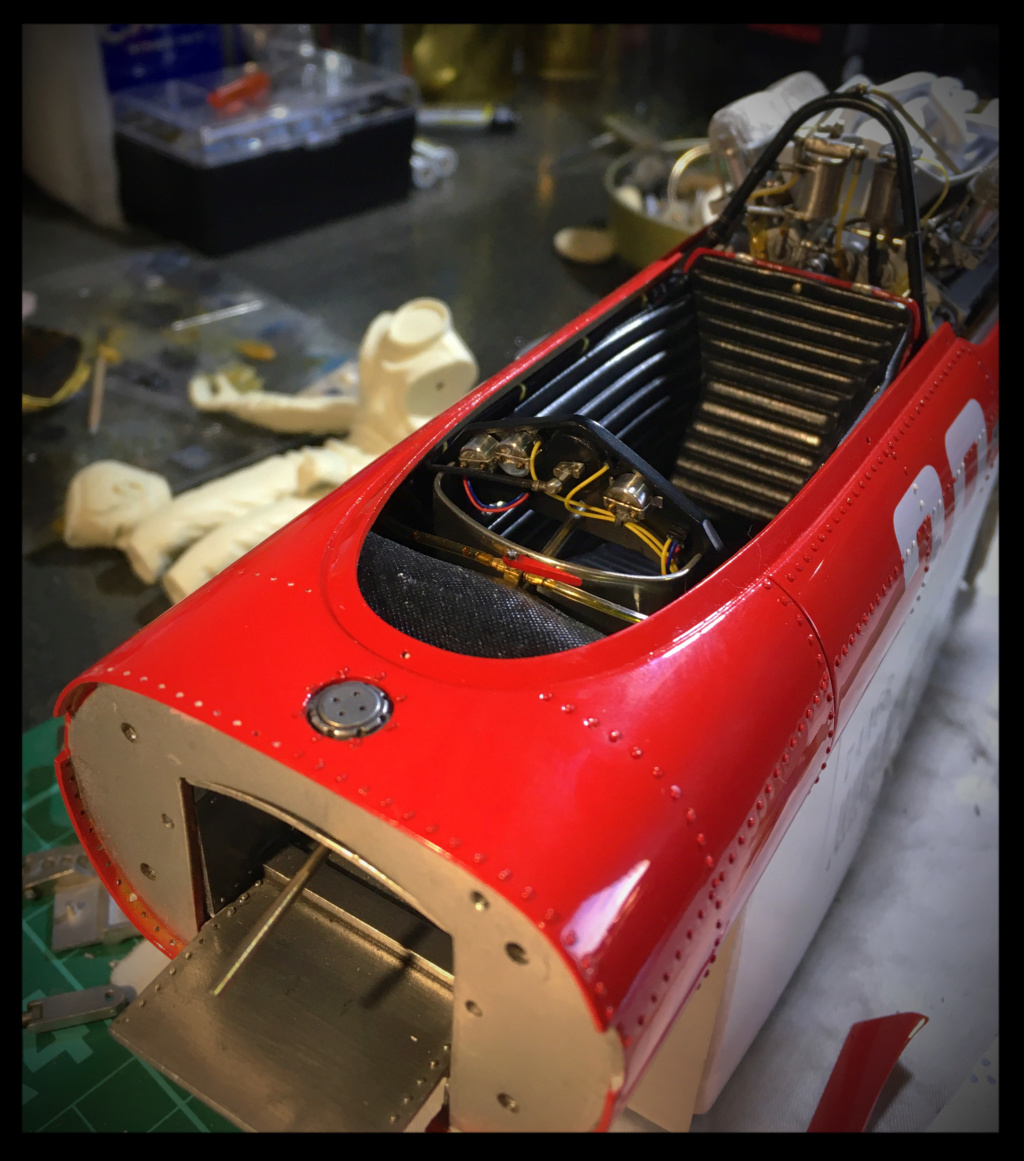

The engine connected to the gear box and vice versa, and install for test fit in its compartment:

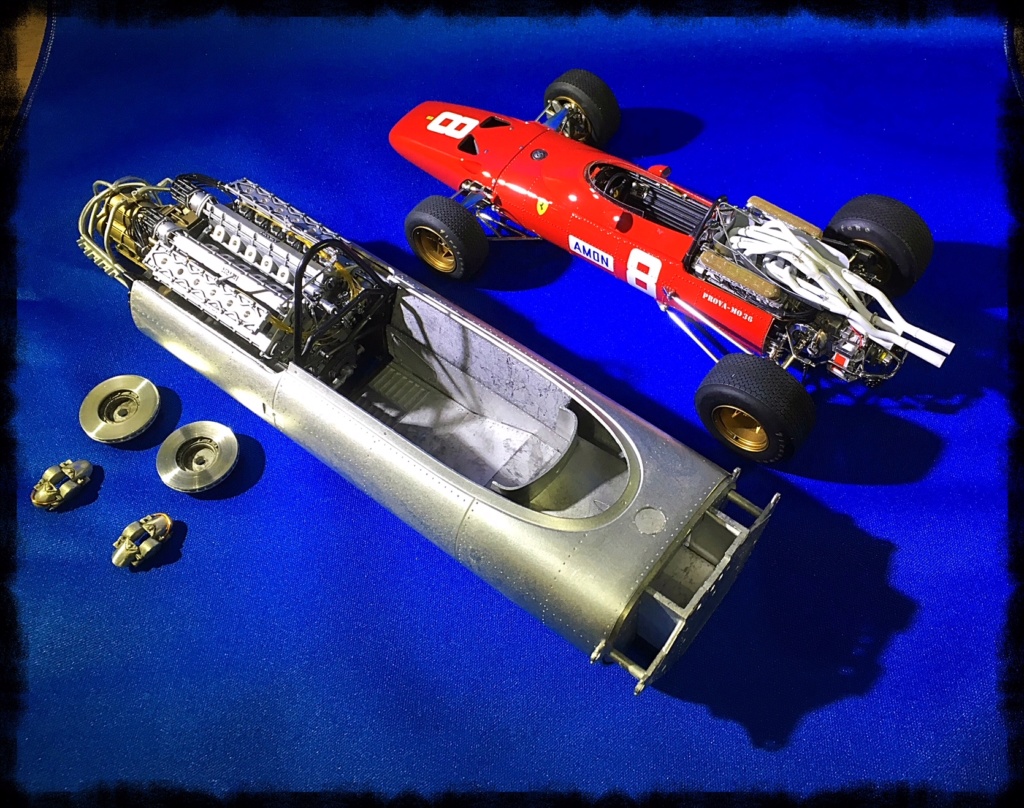

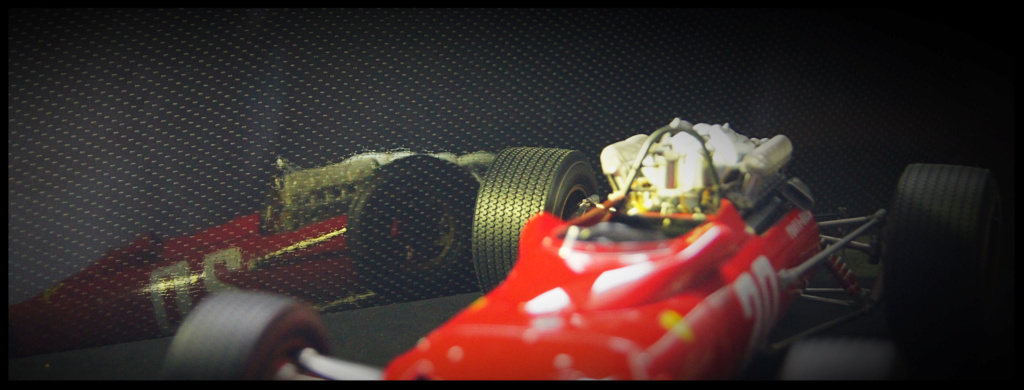

Next to the small 1/20 sister :

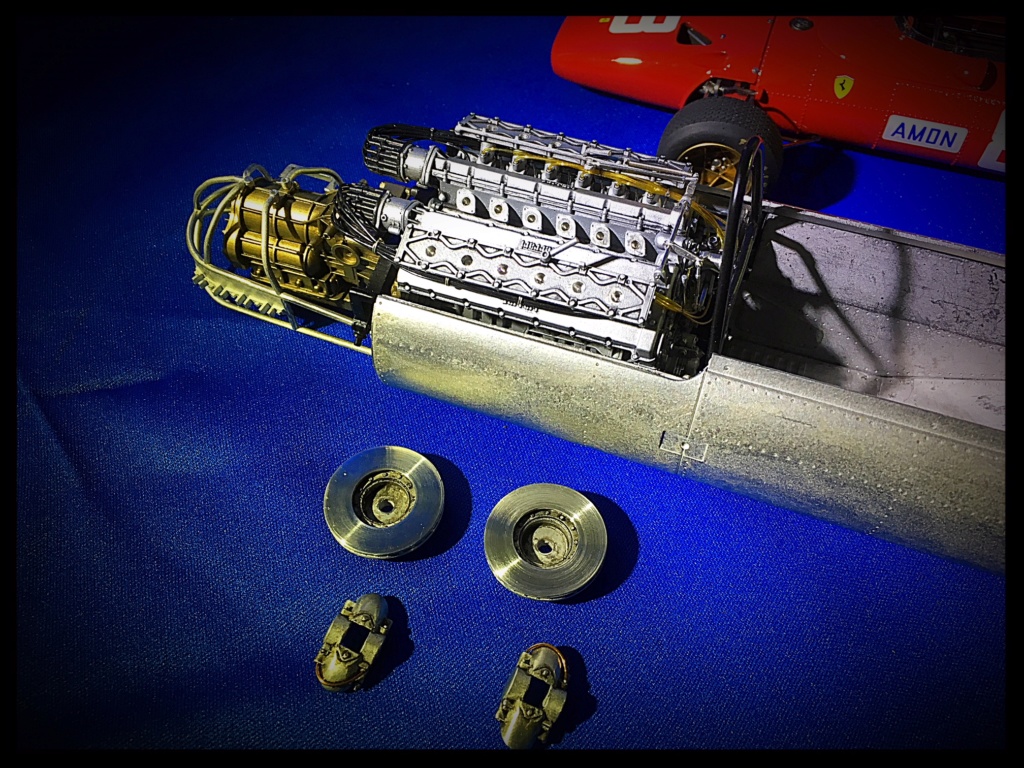

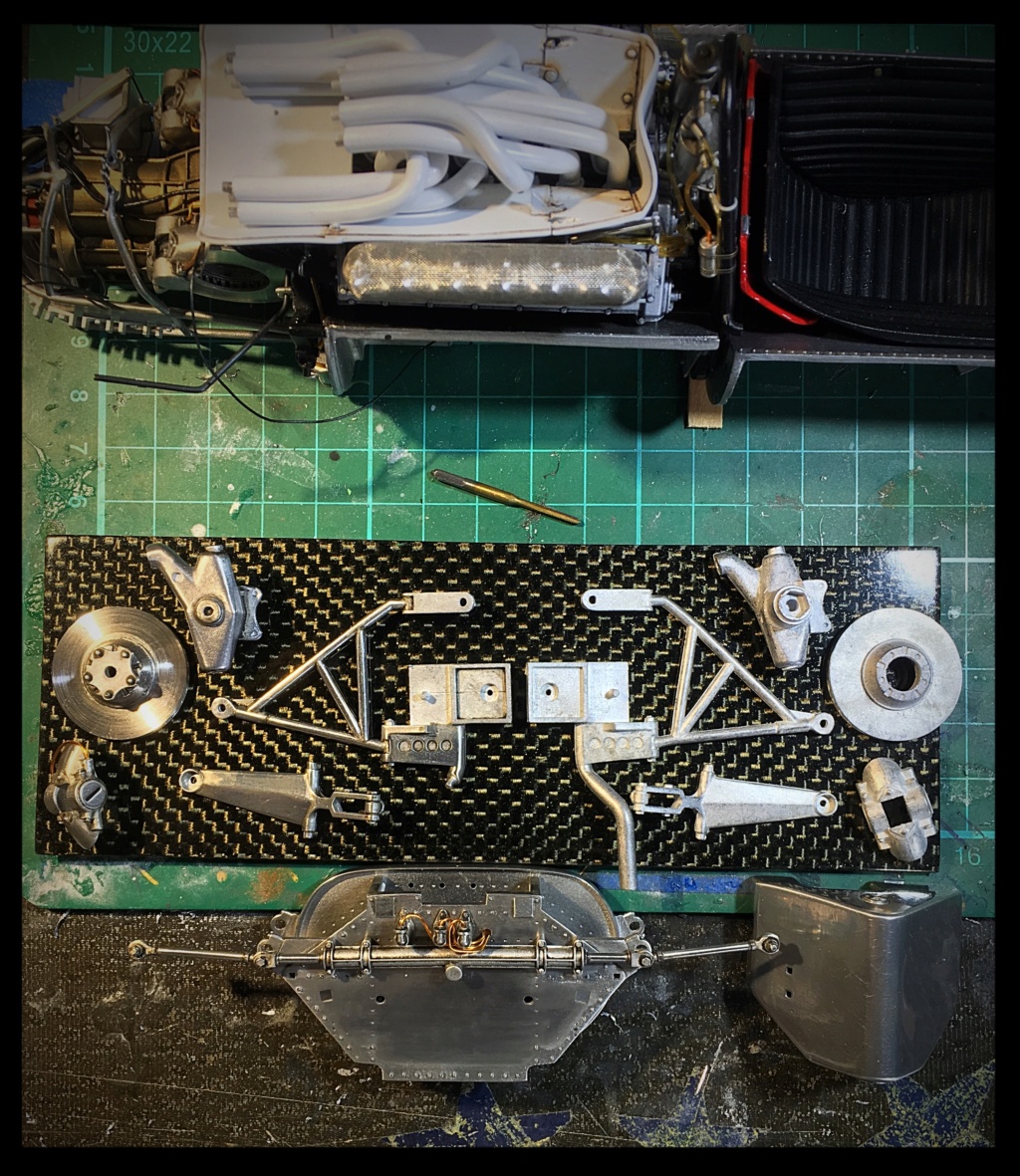

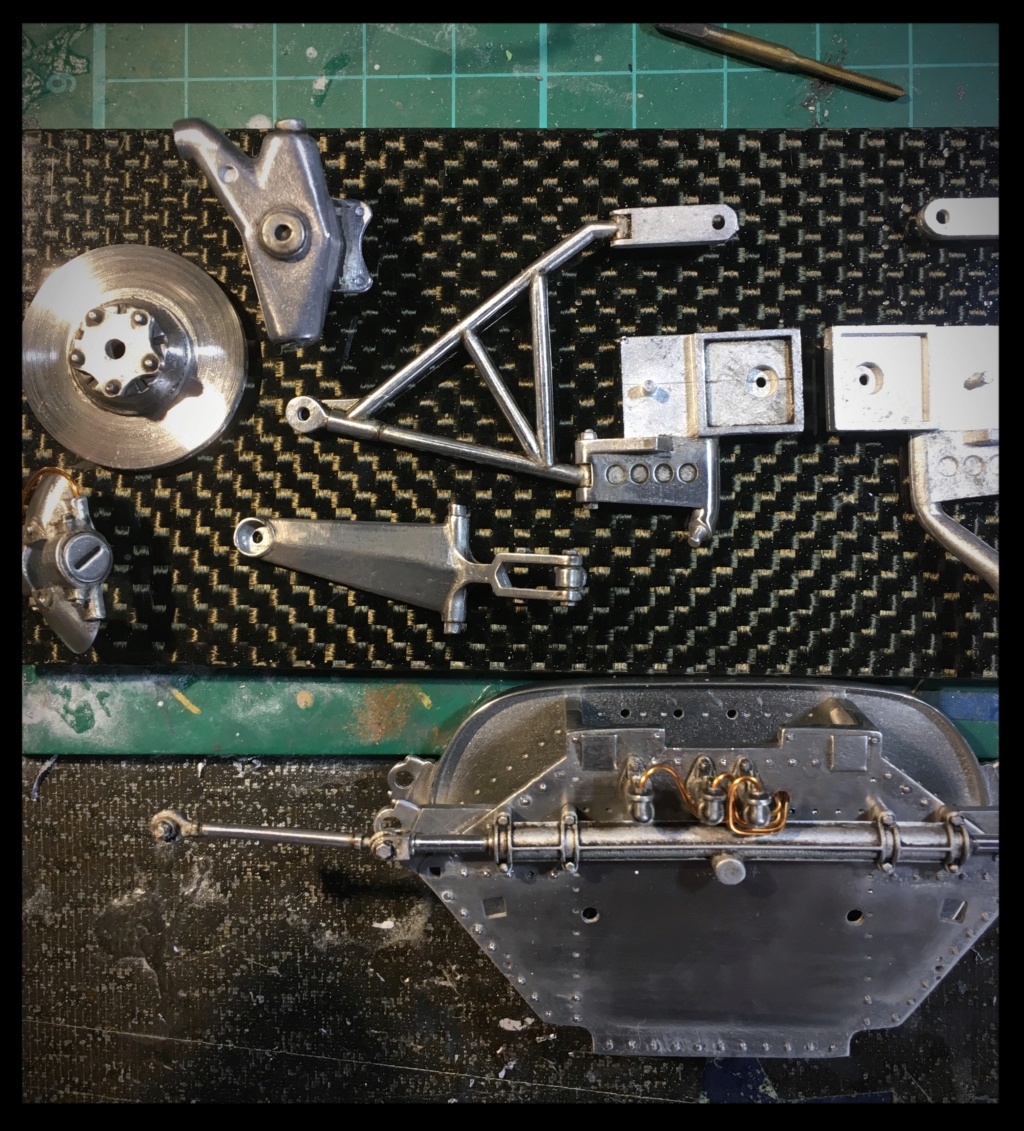

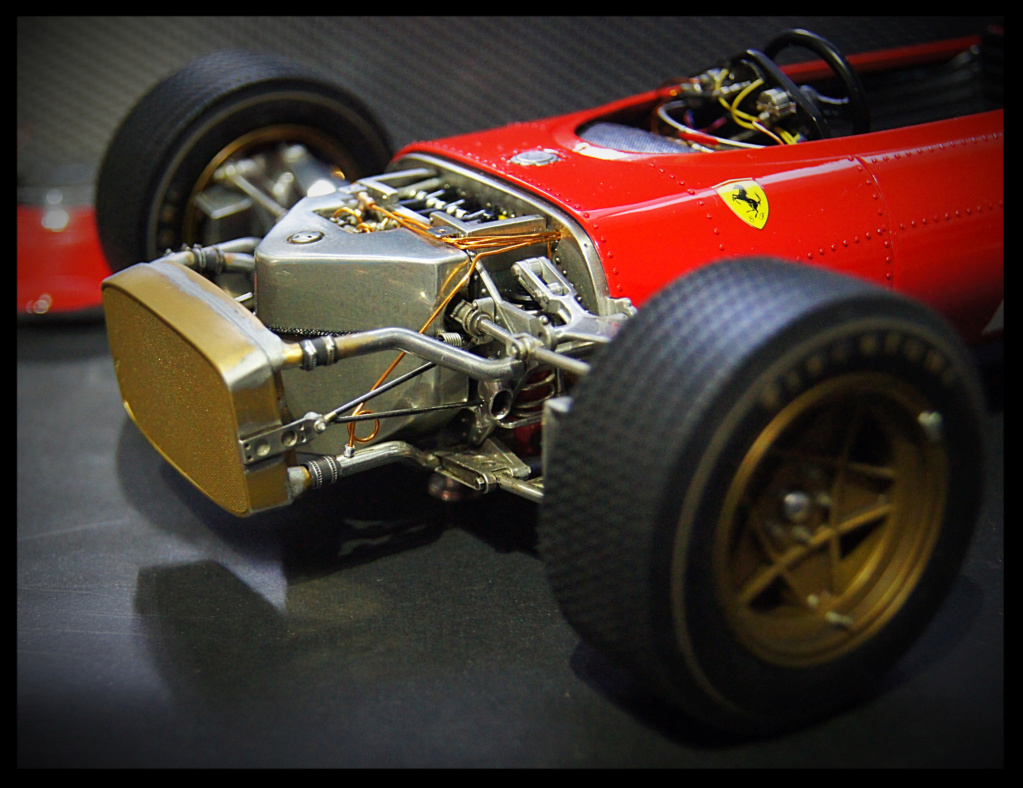

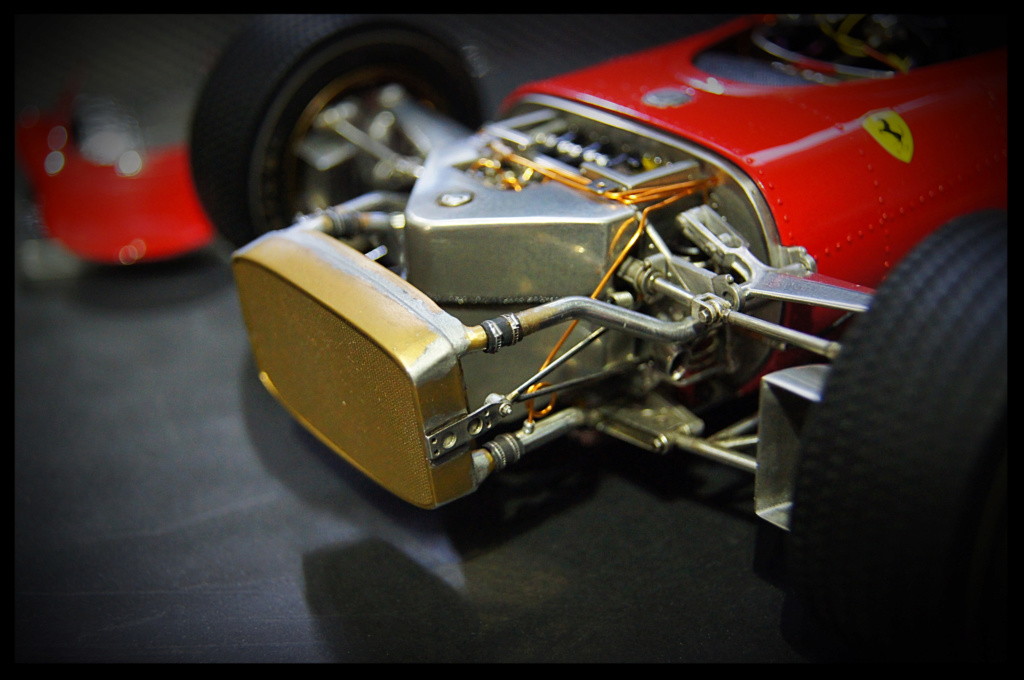

Rear brake discs before assembly on the gear box:

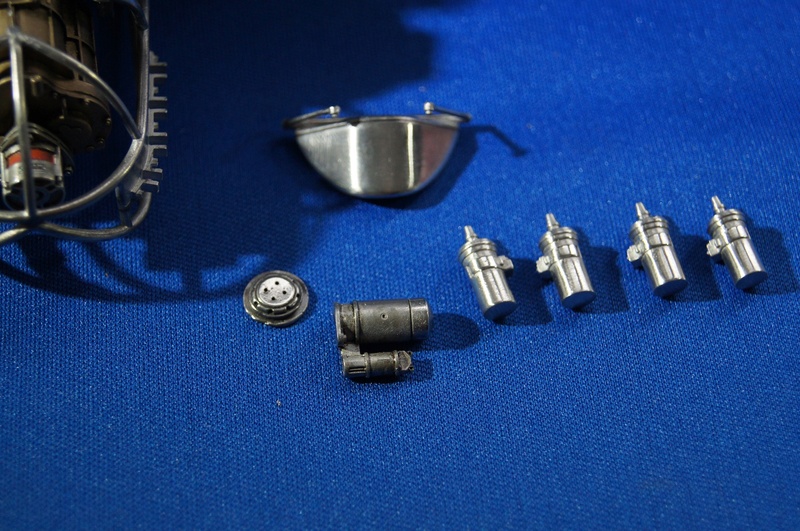

... and few accessories:

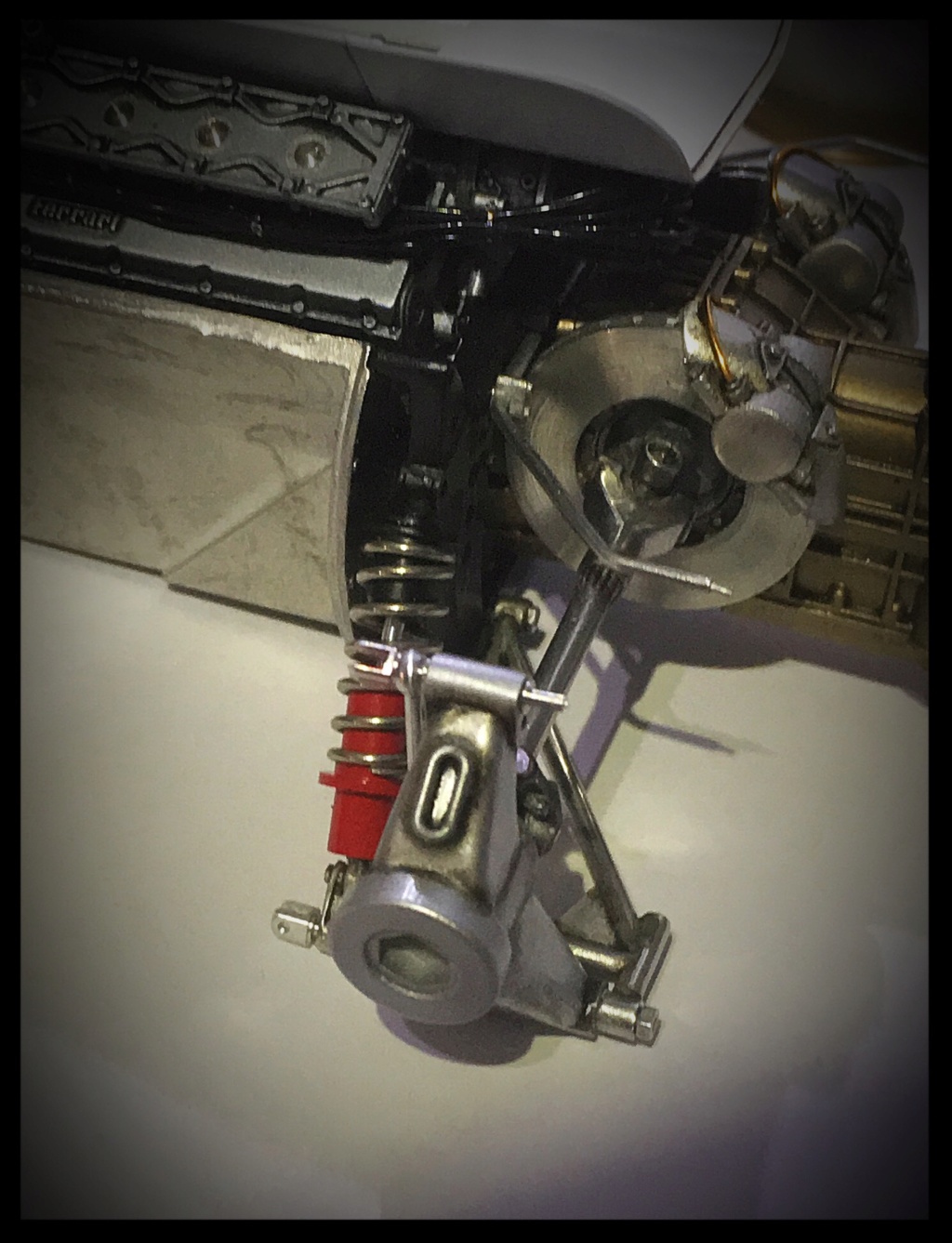

Modification of the rear hubs in order to adapt machined parts:

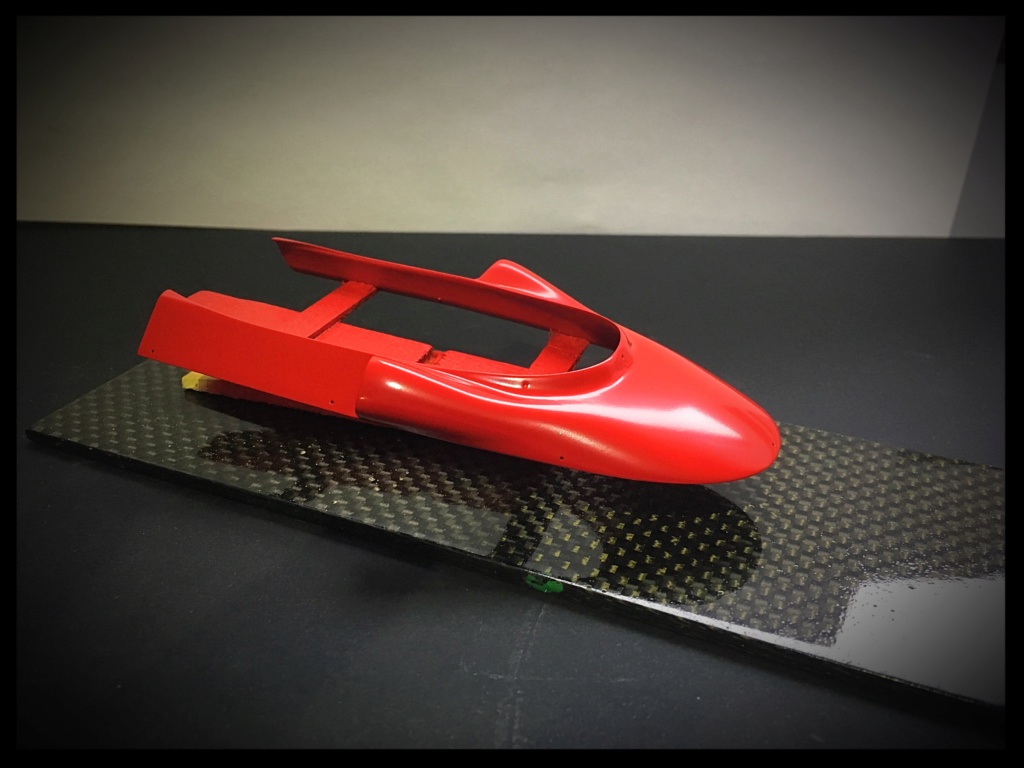

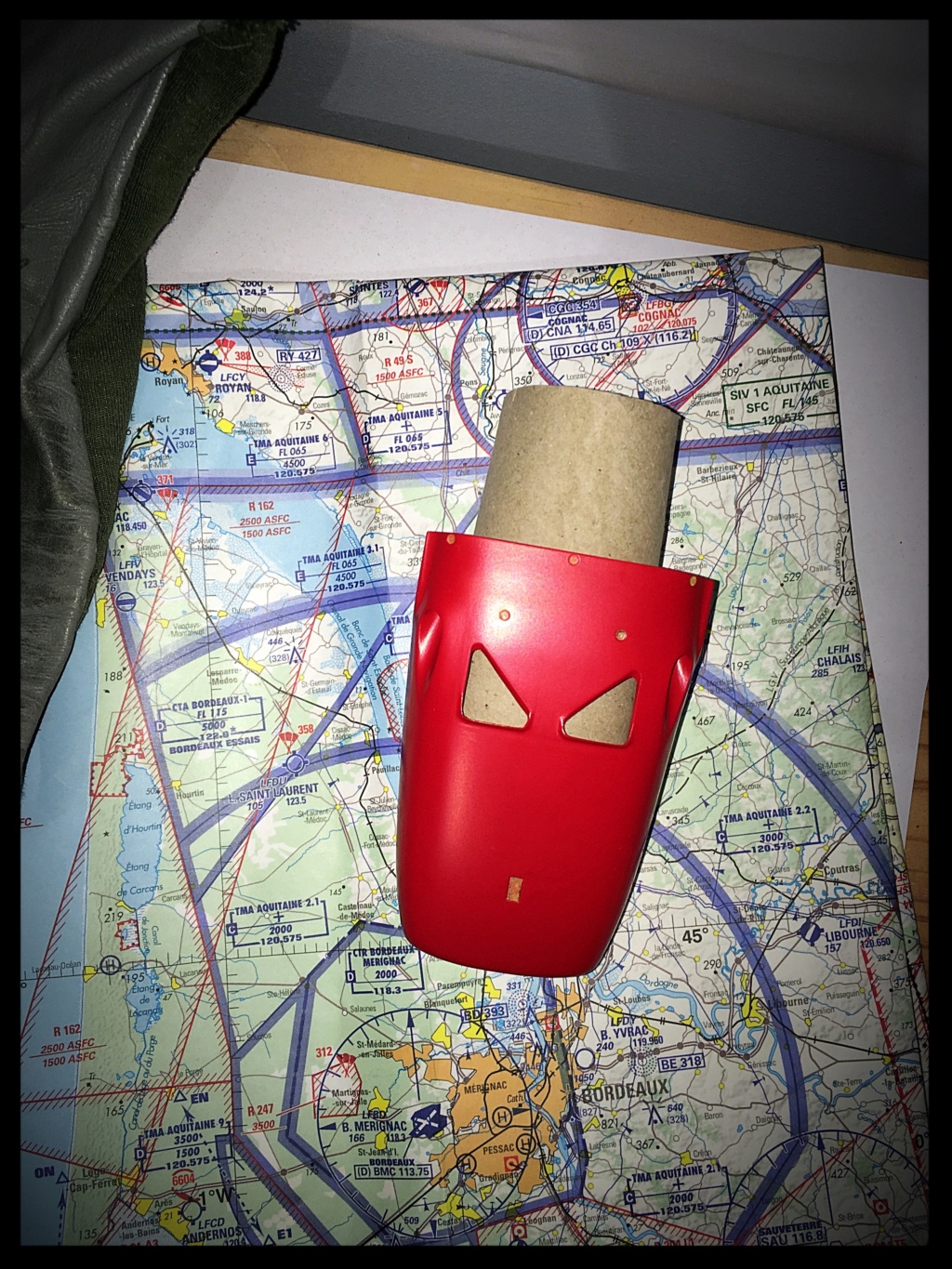

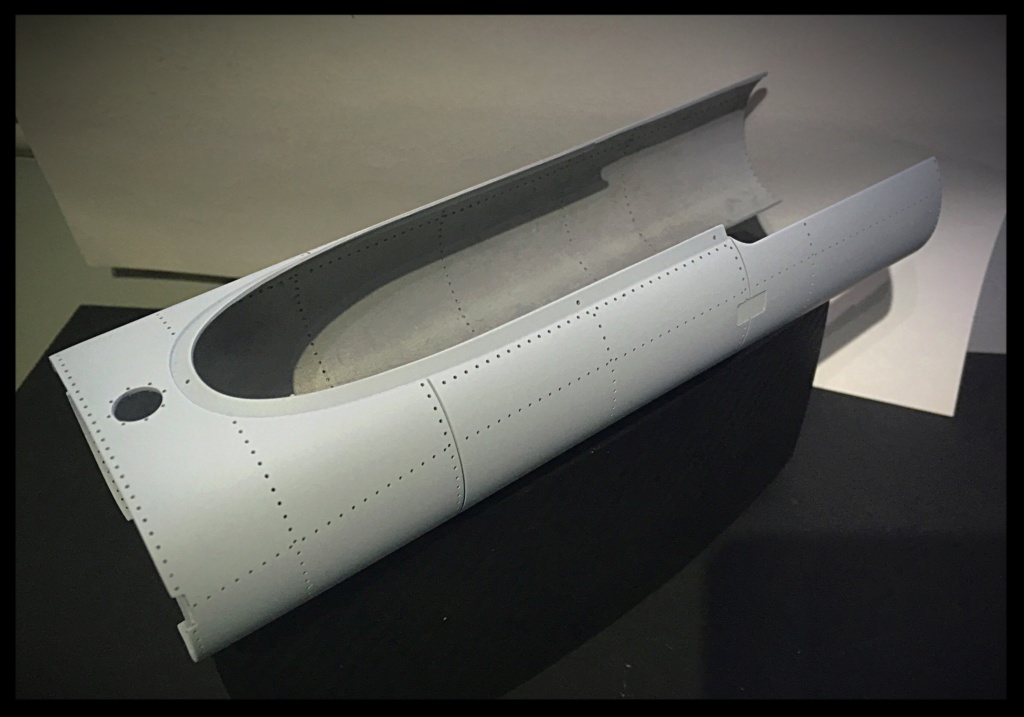

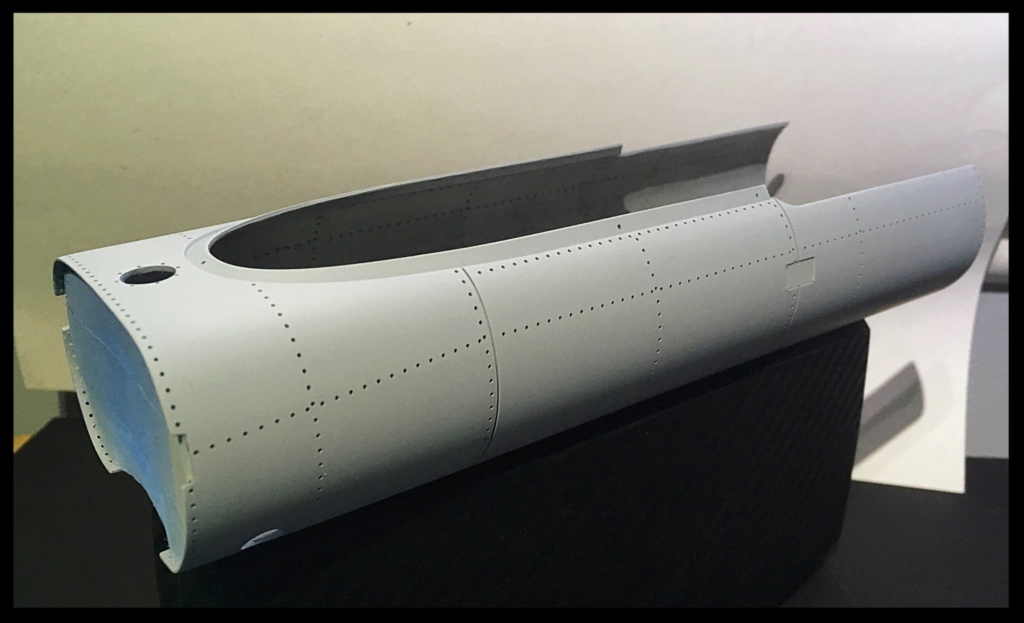

Time for primer:

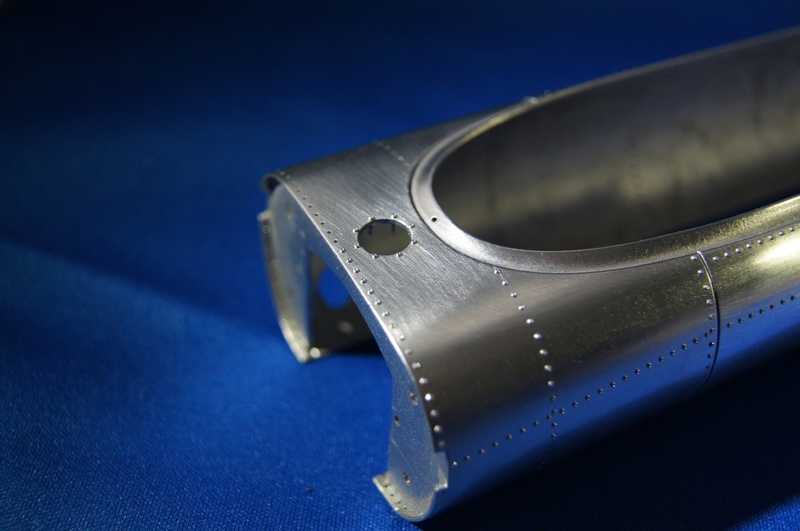

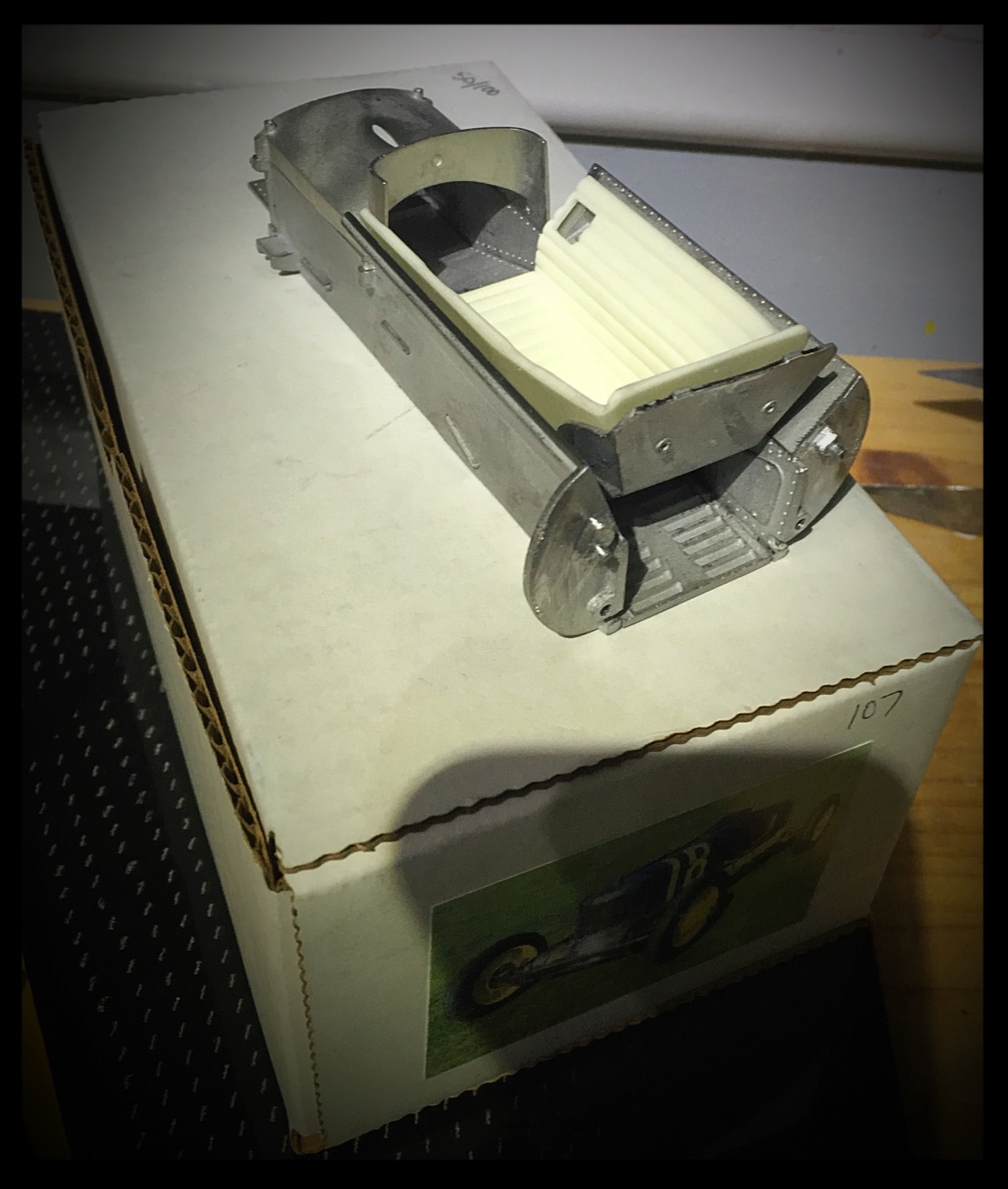

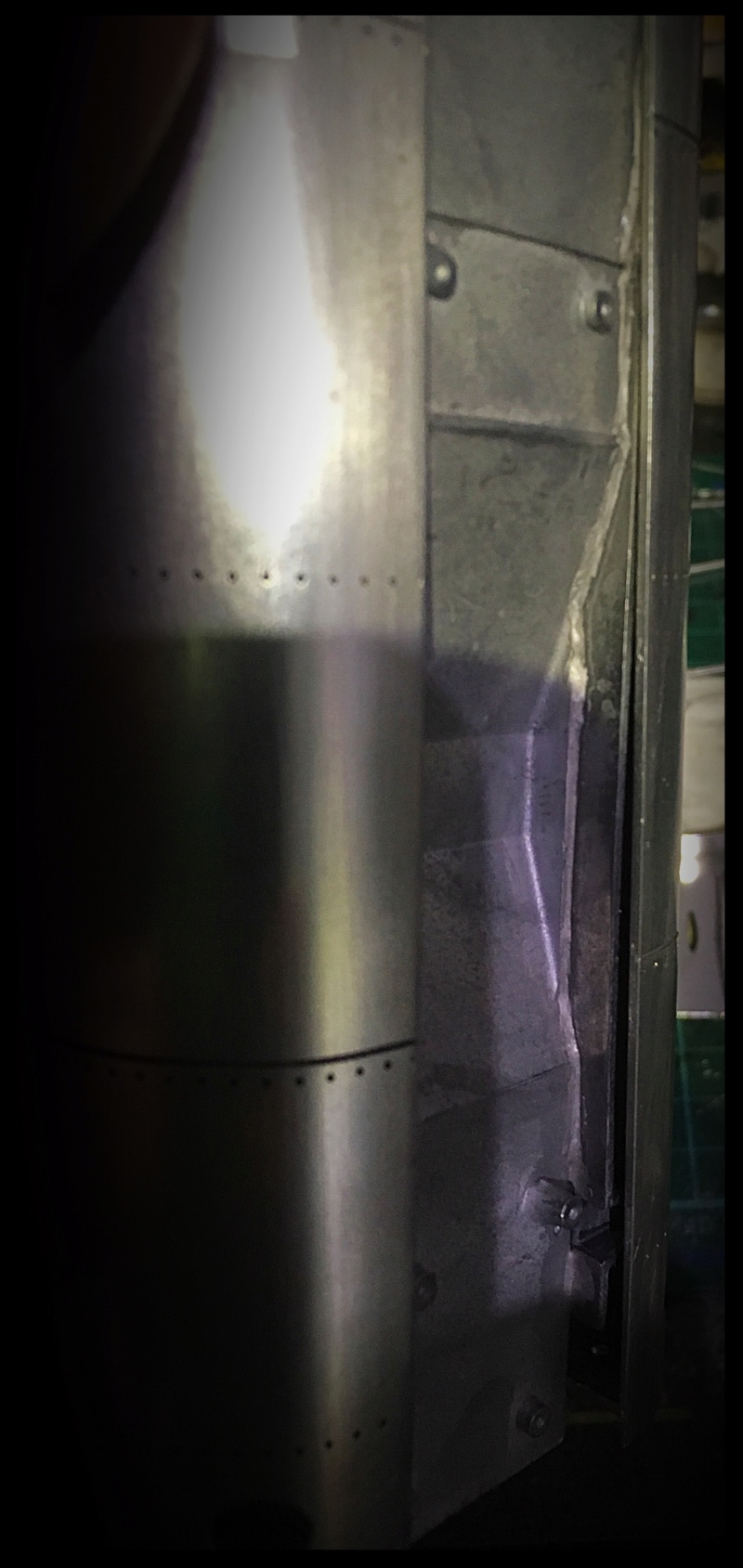

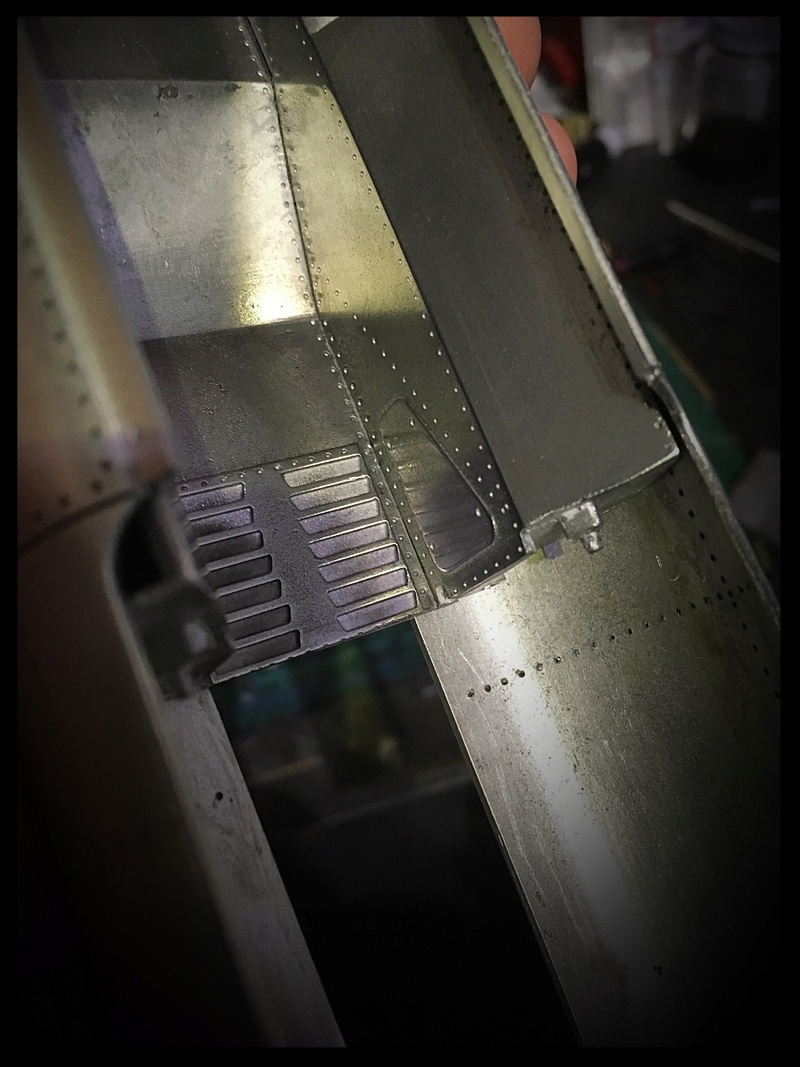

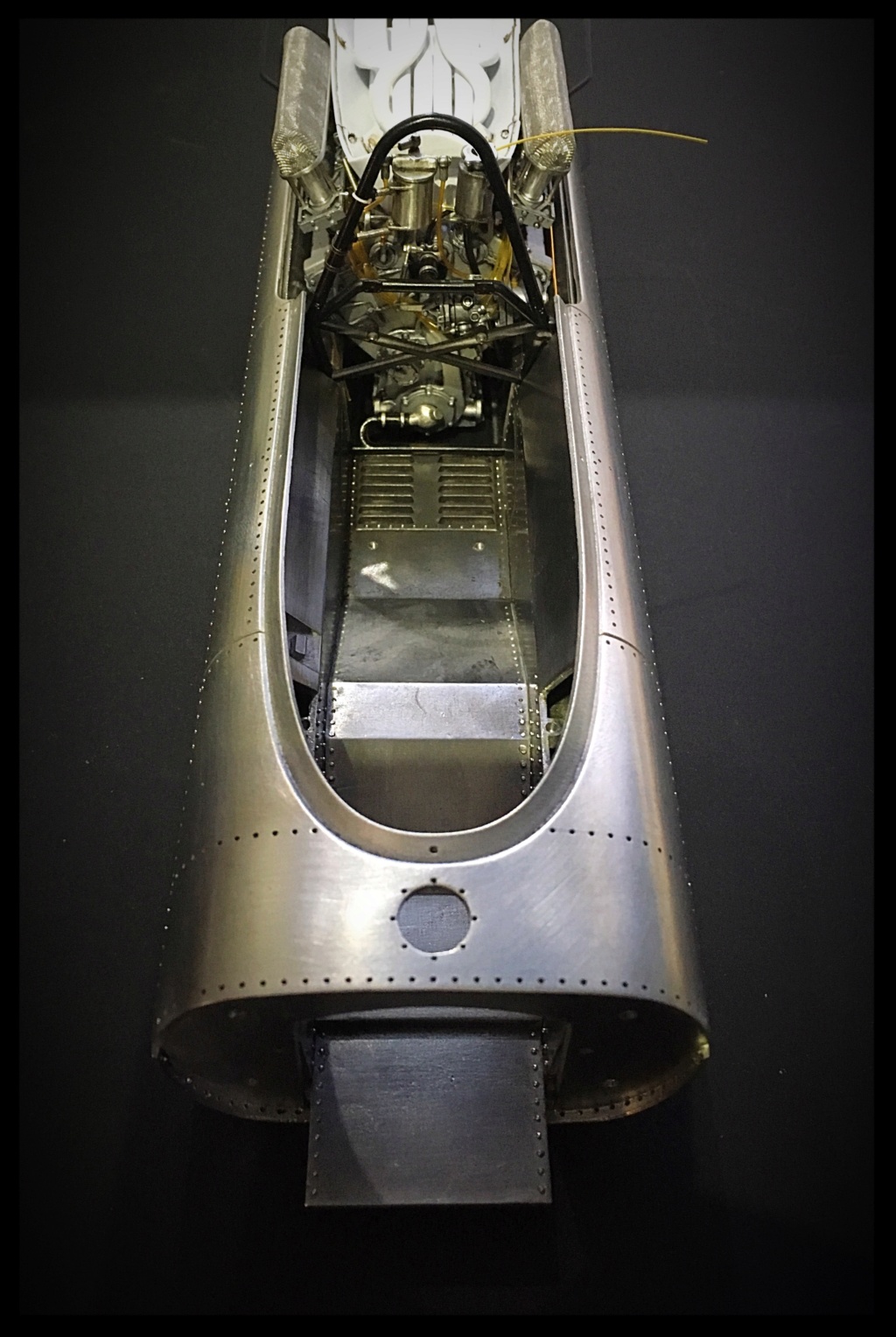

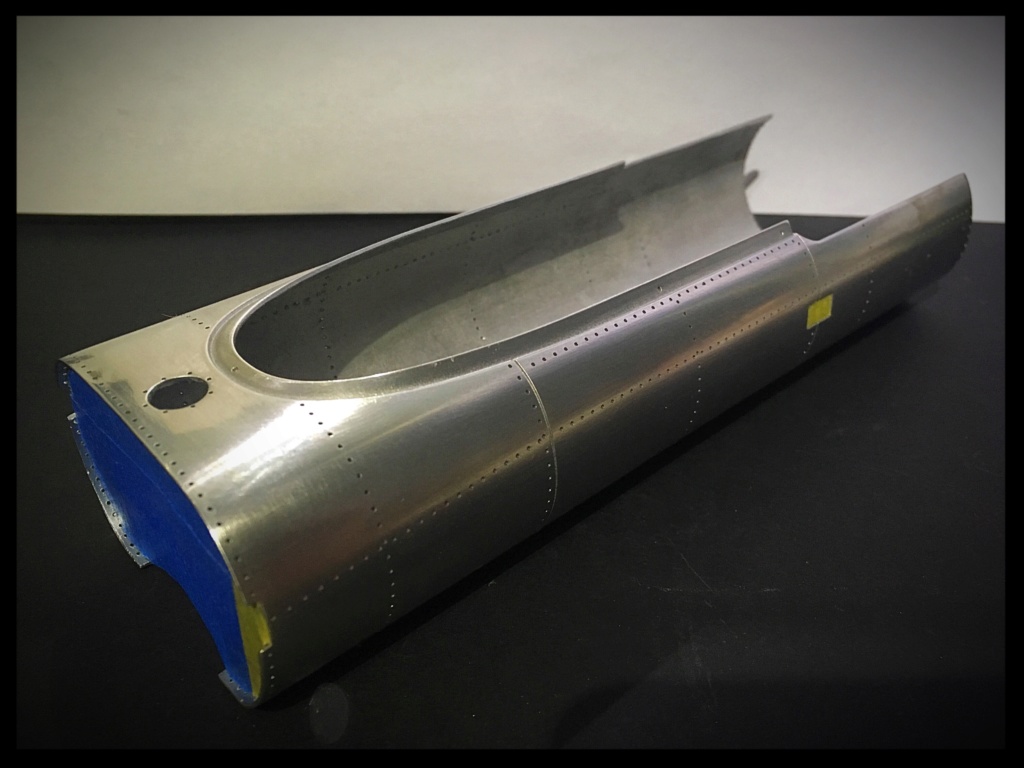

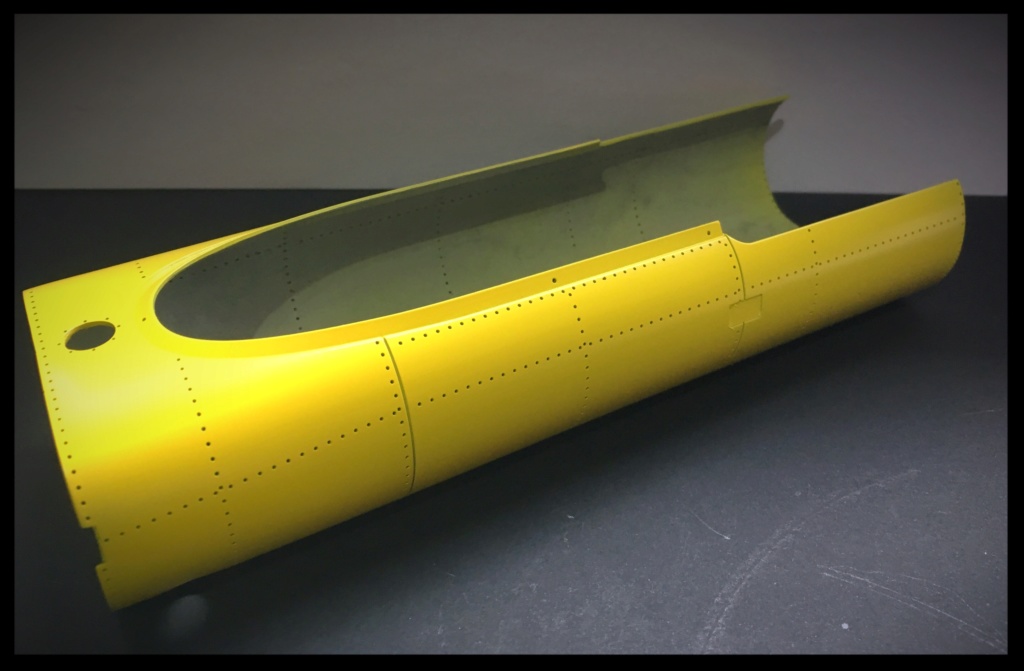

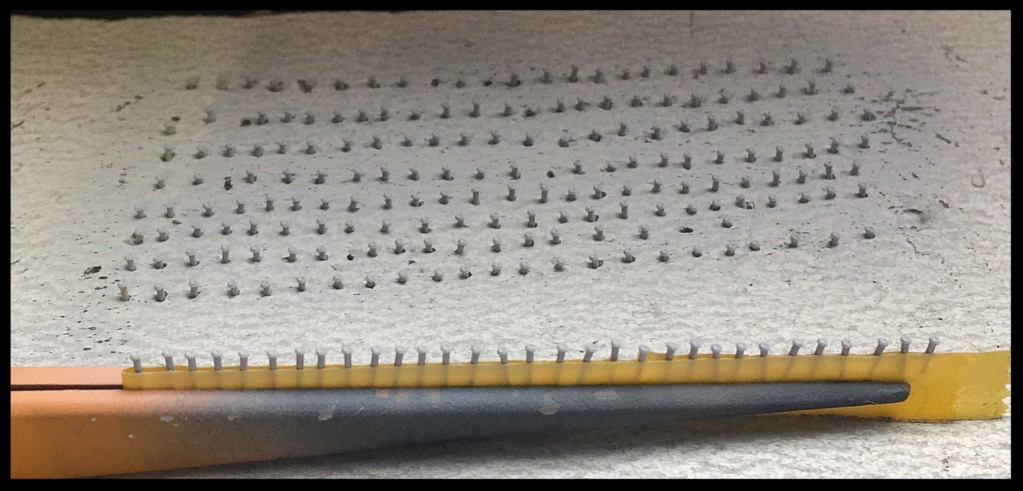

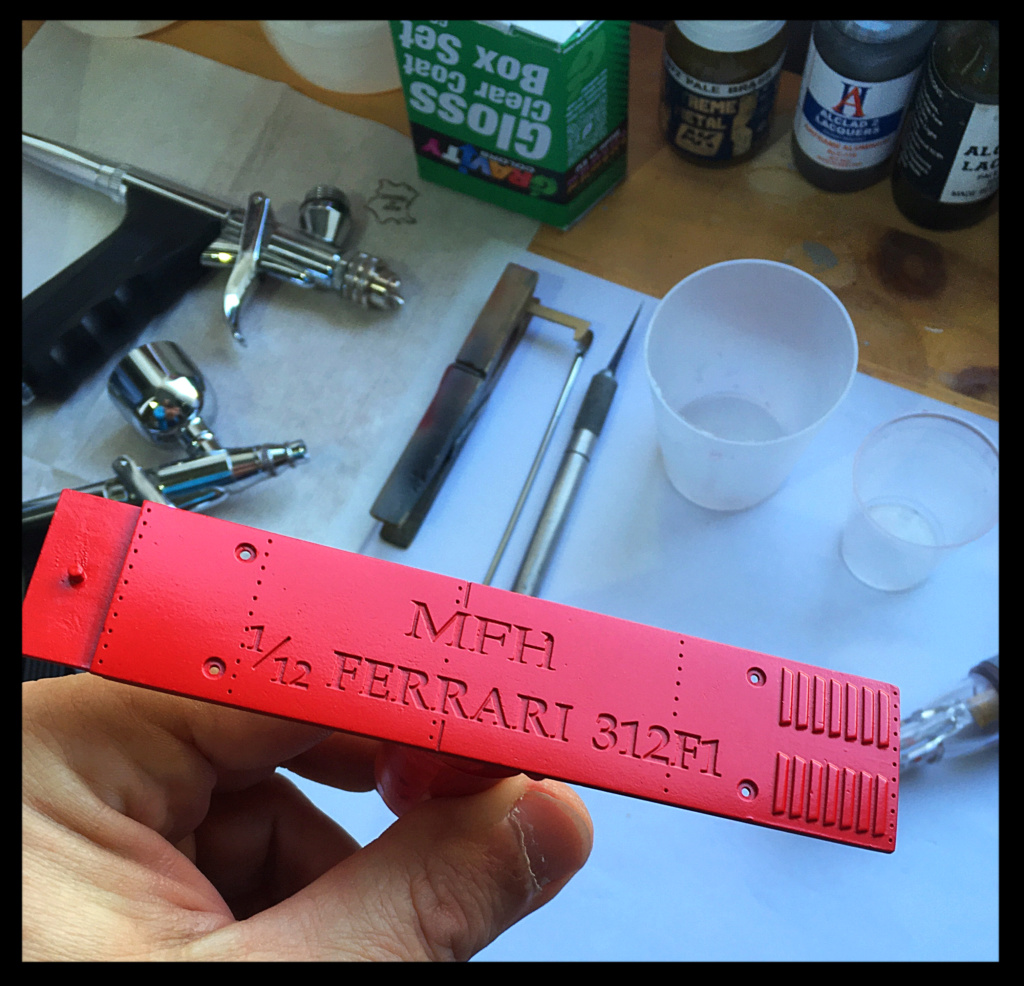

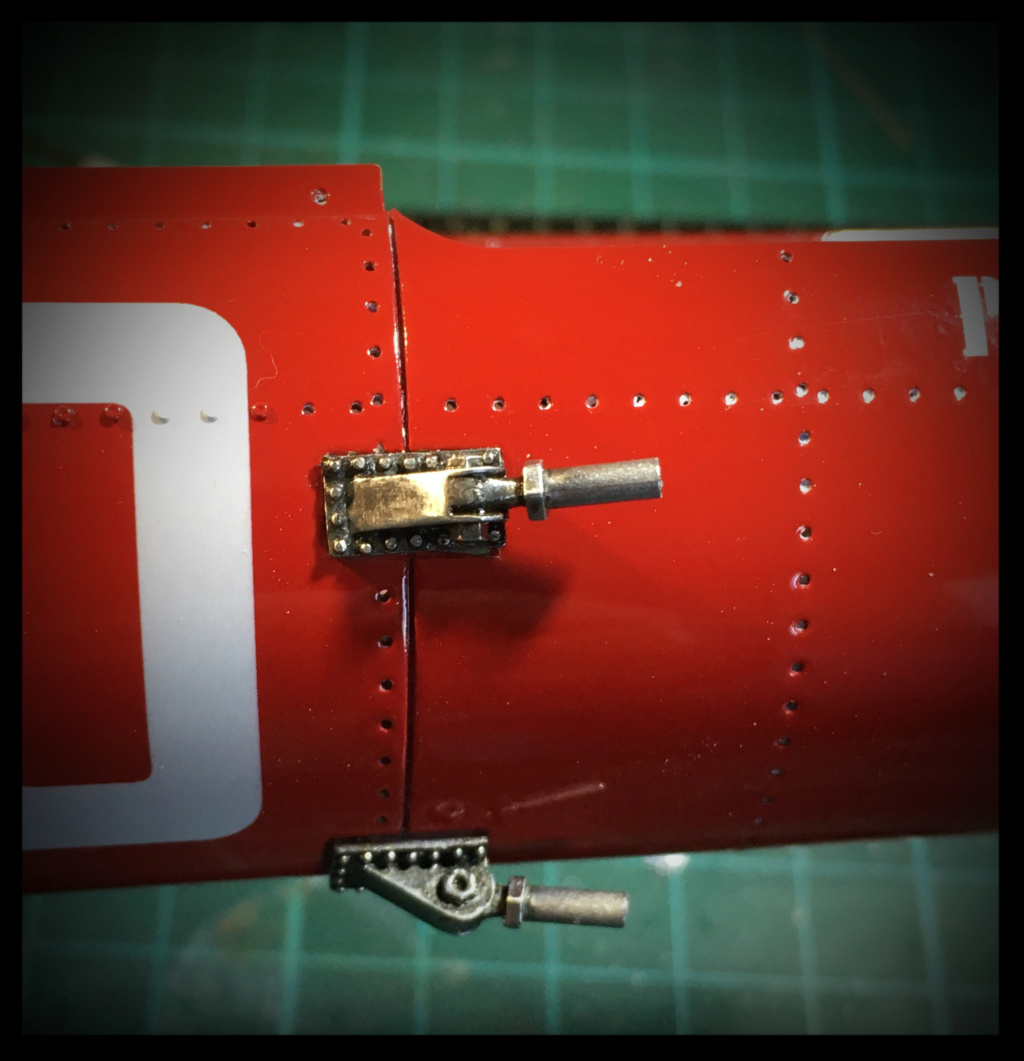

The body is drilled in order to be riveted with MFH aluminium rivet:

The engine is... big. Almost the size of the 1/20 kit:

Rosso Corsa GC and Semi Gloss Black ZP on the rear shocks and the steering wheel.

Dull Aluminium (Alclad) on the rear hubs

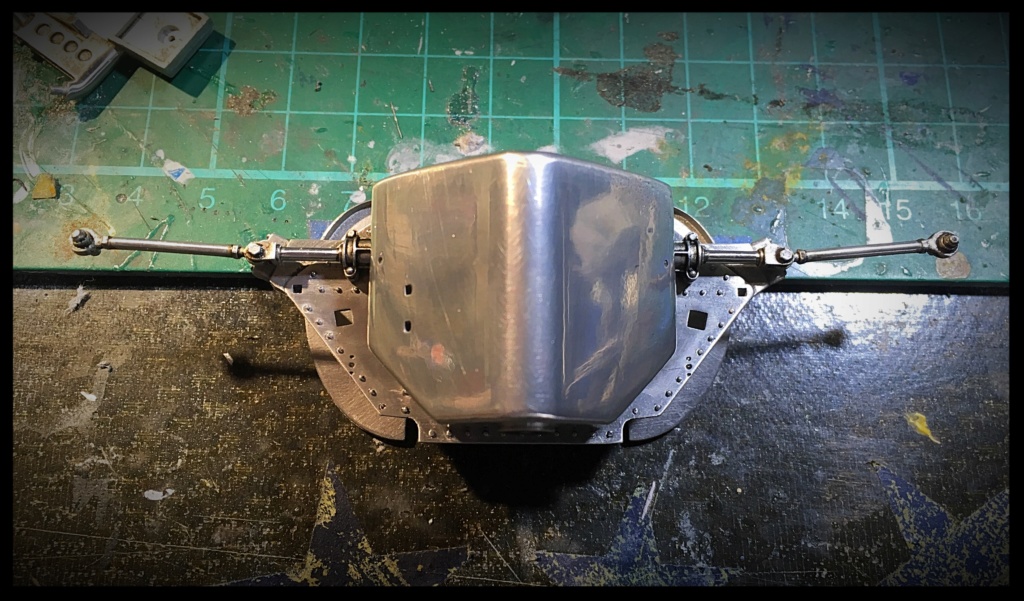

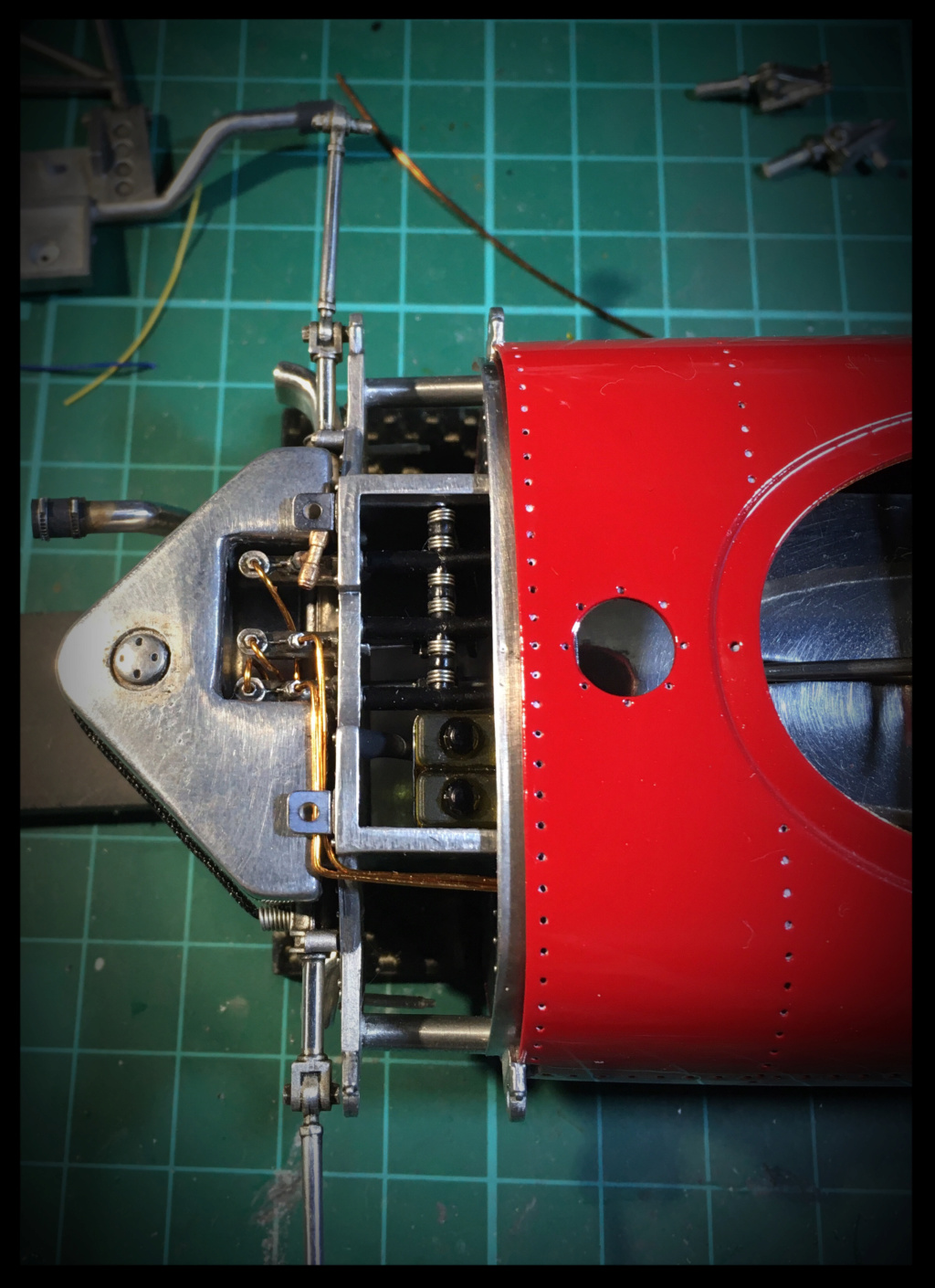

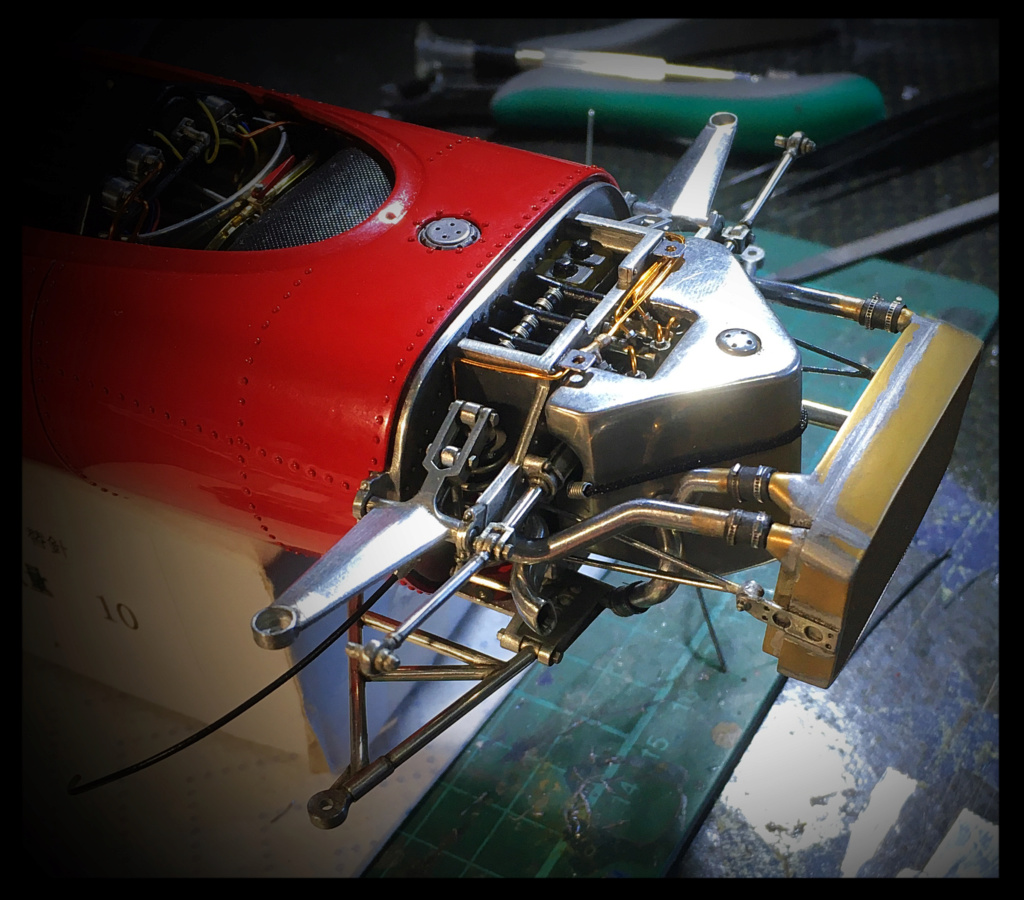

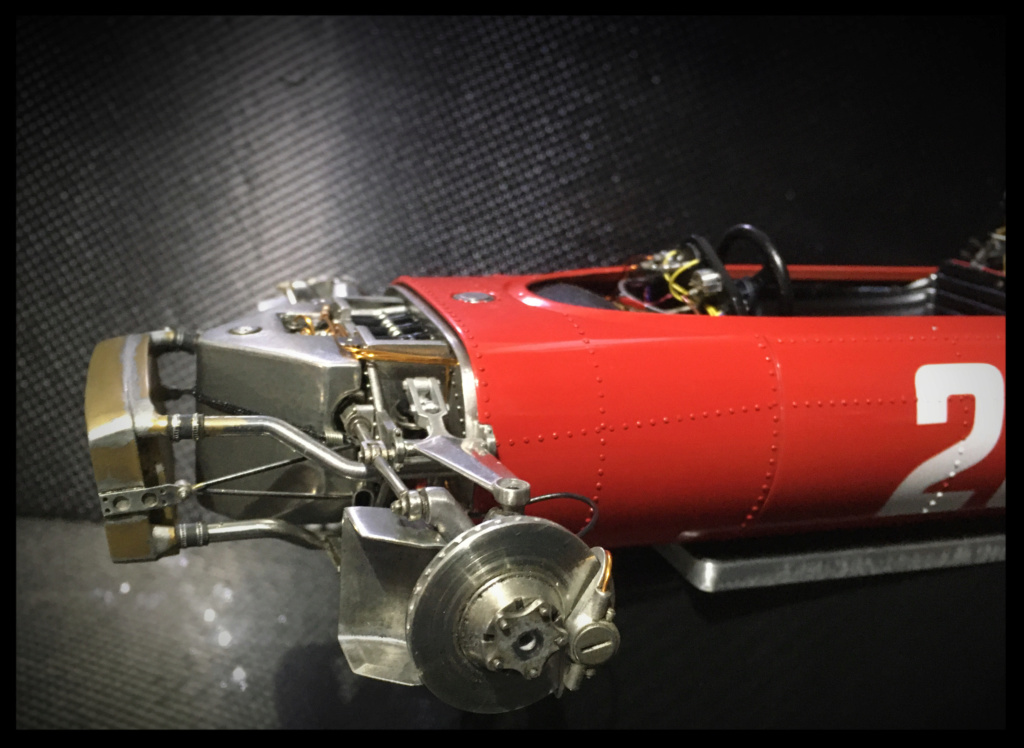

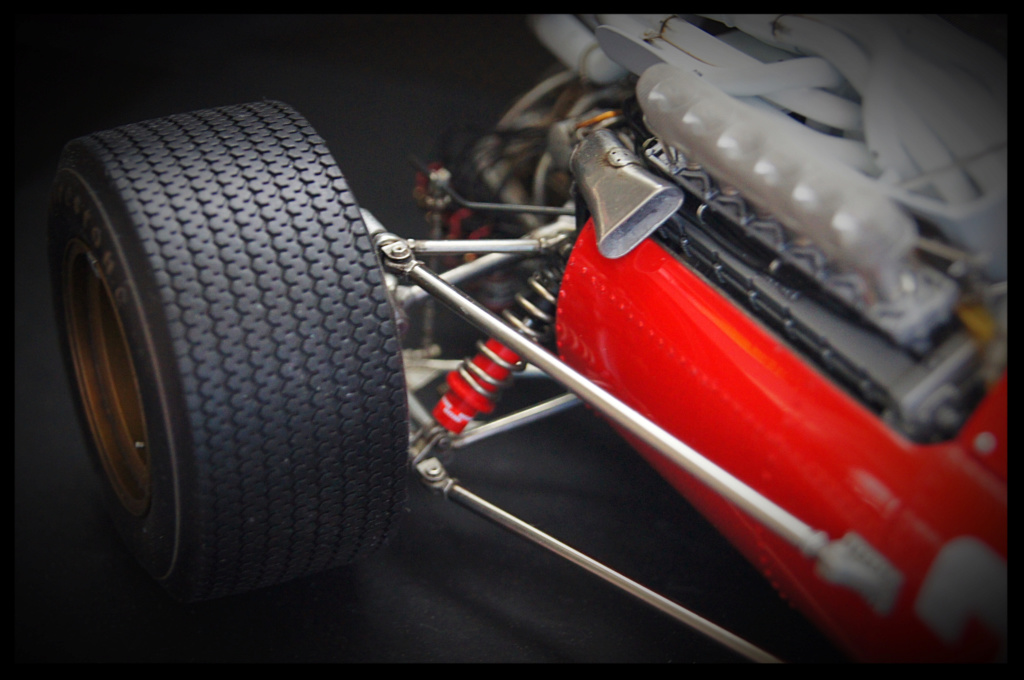

Test fit of the front end:

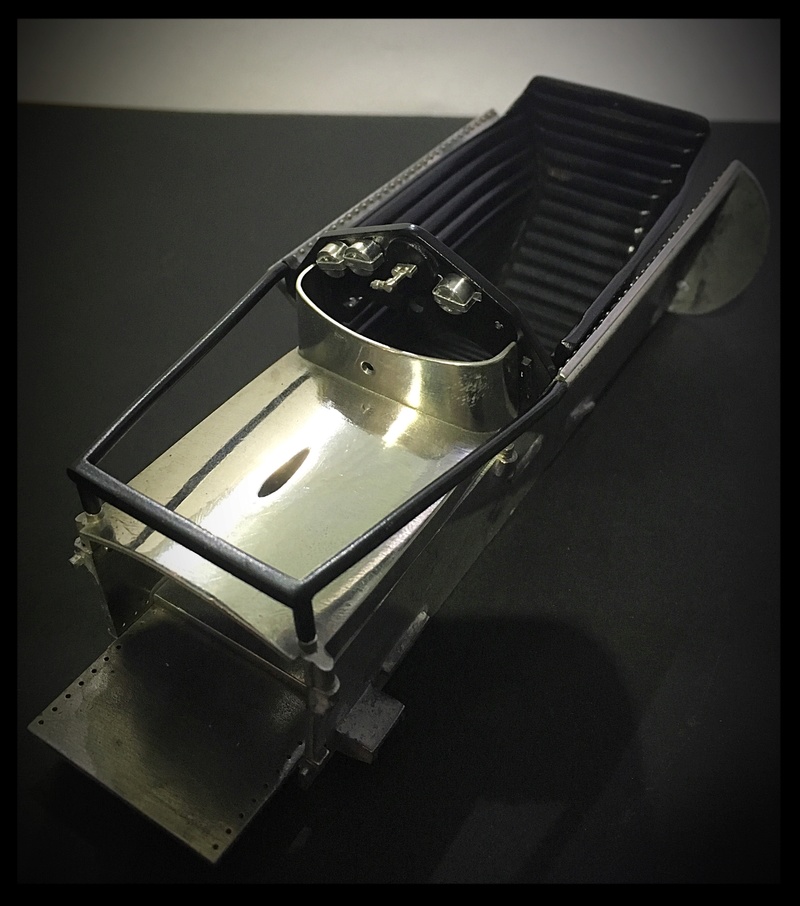

Heat shield adjusted and drilled for the roll cage:

Titanium White GC:

Not very happy with the Dull Alu, so black Alclad is sprayed:

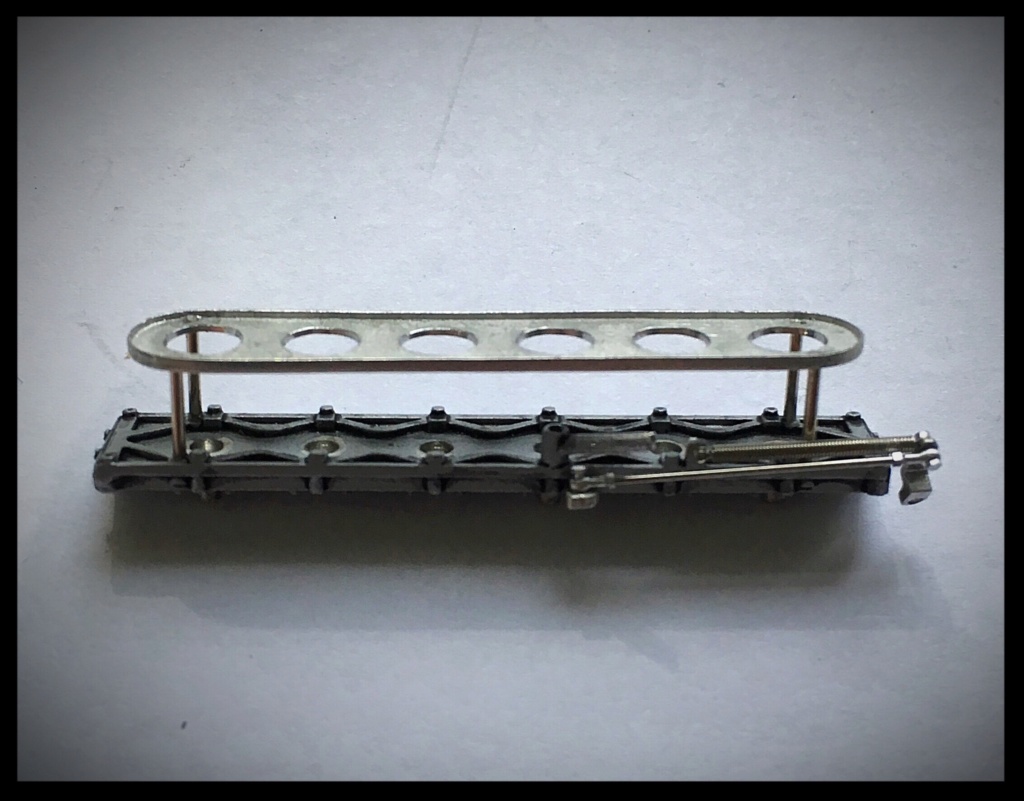

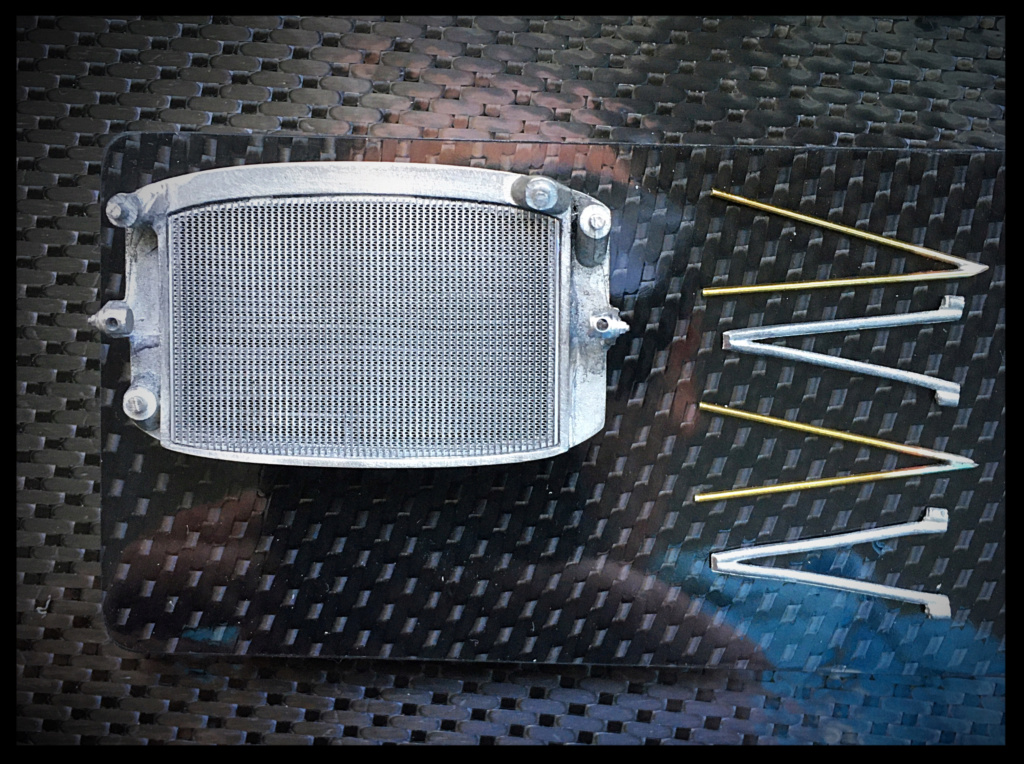

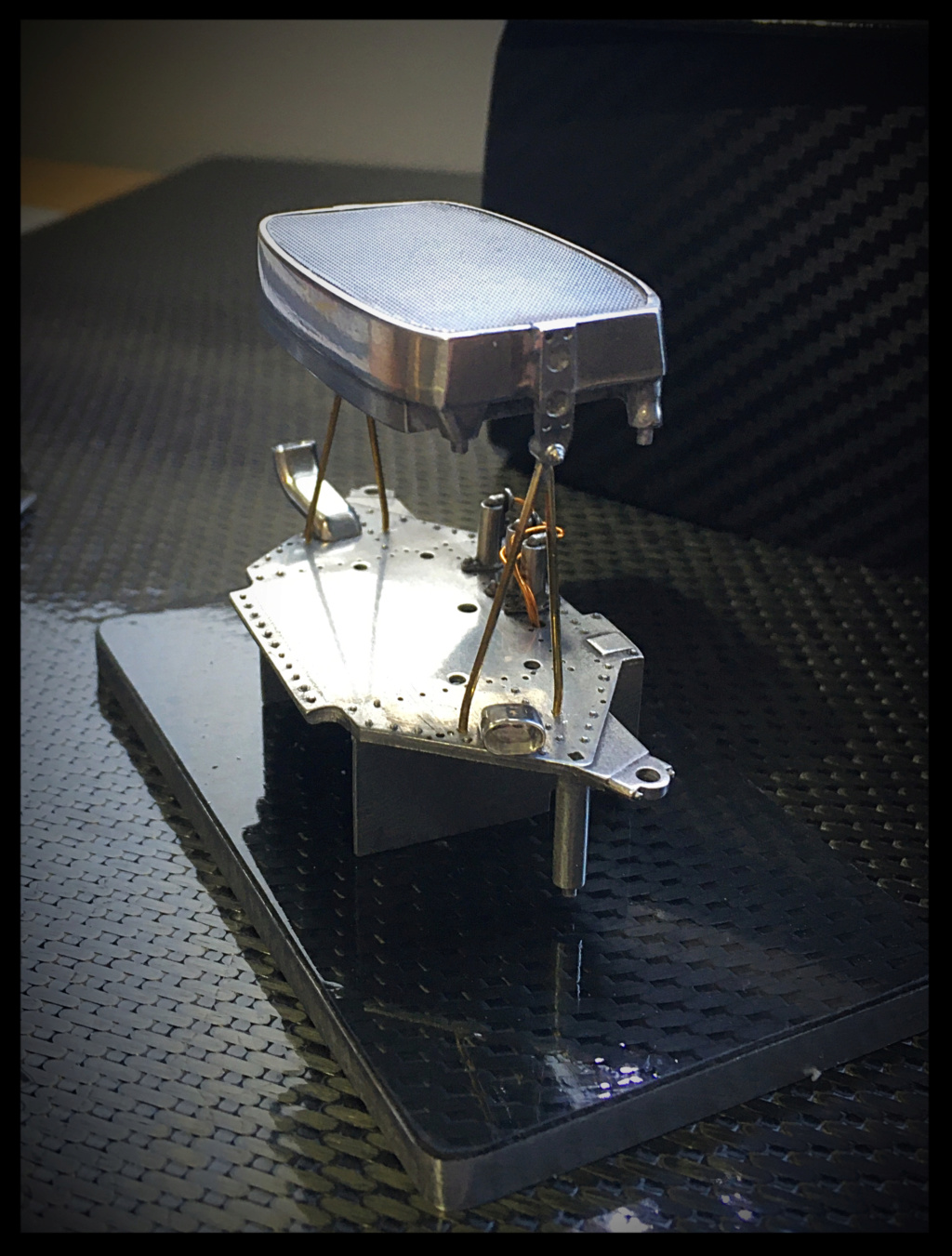

Tubes installed in the radiator and started to work on the rear

suspension components:

Front brakes scoops are painted white:

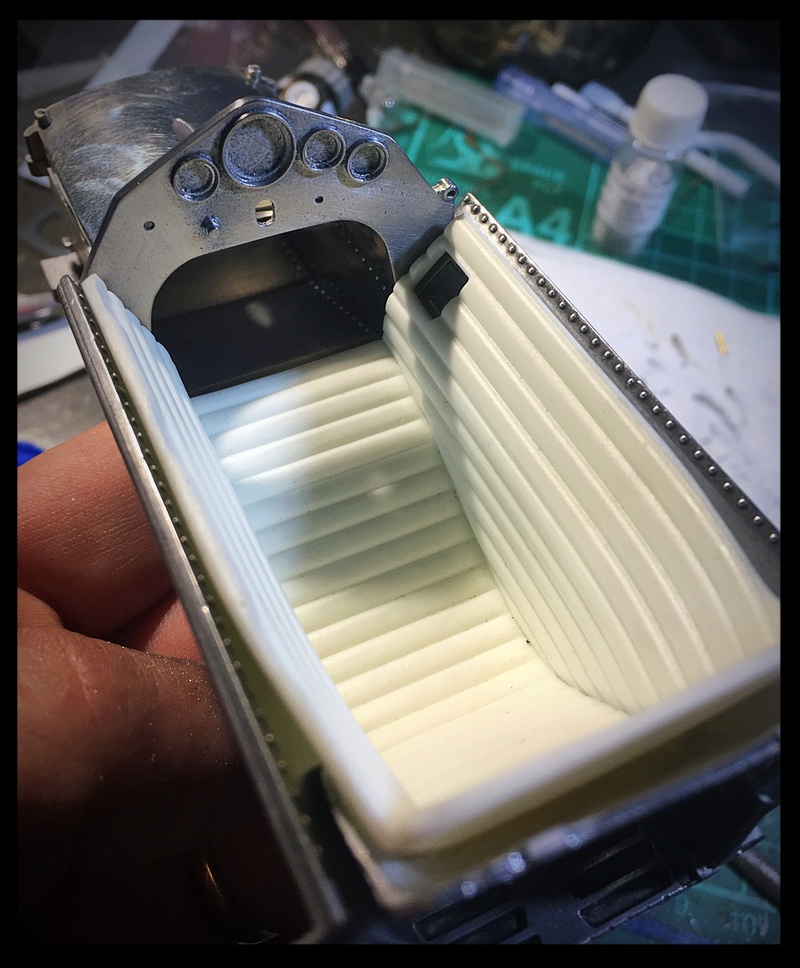

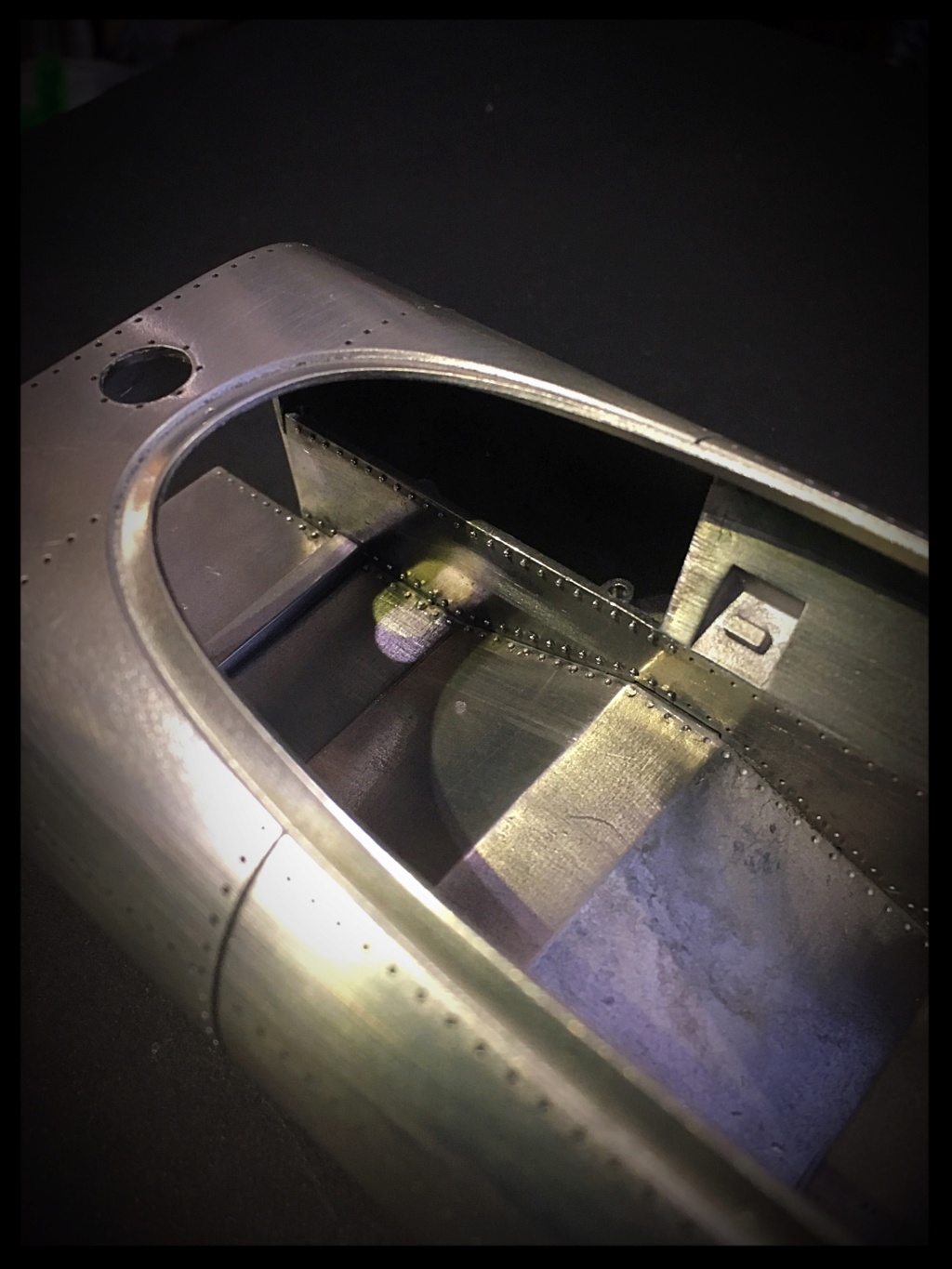

test fitting of the bathtub:

Weld seams on the 3in1 exhaust parts:

I really apologize for the poor quality of the pictures...

Alclad White Alu and Klear Kote.

Paint family picture:

Wheels prep & paint session:

Primer:

Alclad Black:

Pale Gold Alclad:

Masking off:

Time for oils:

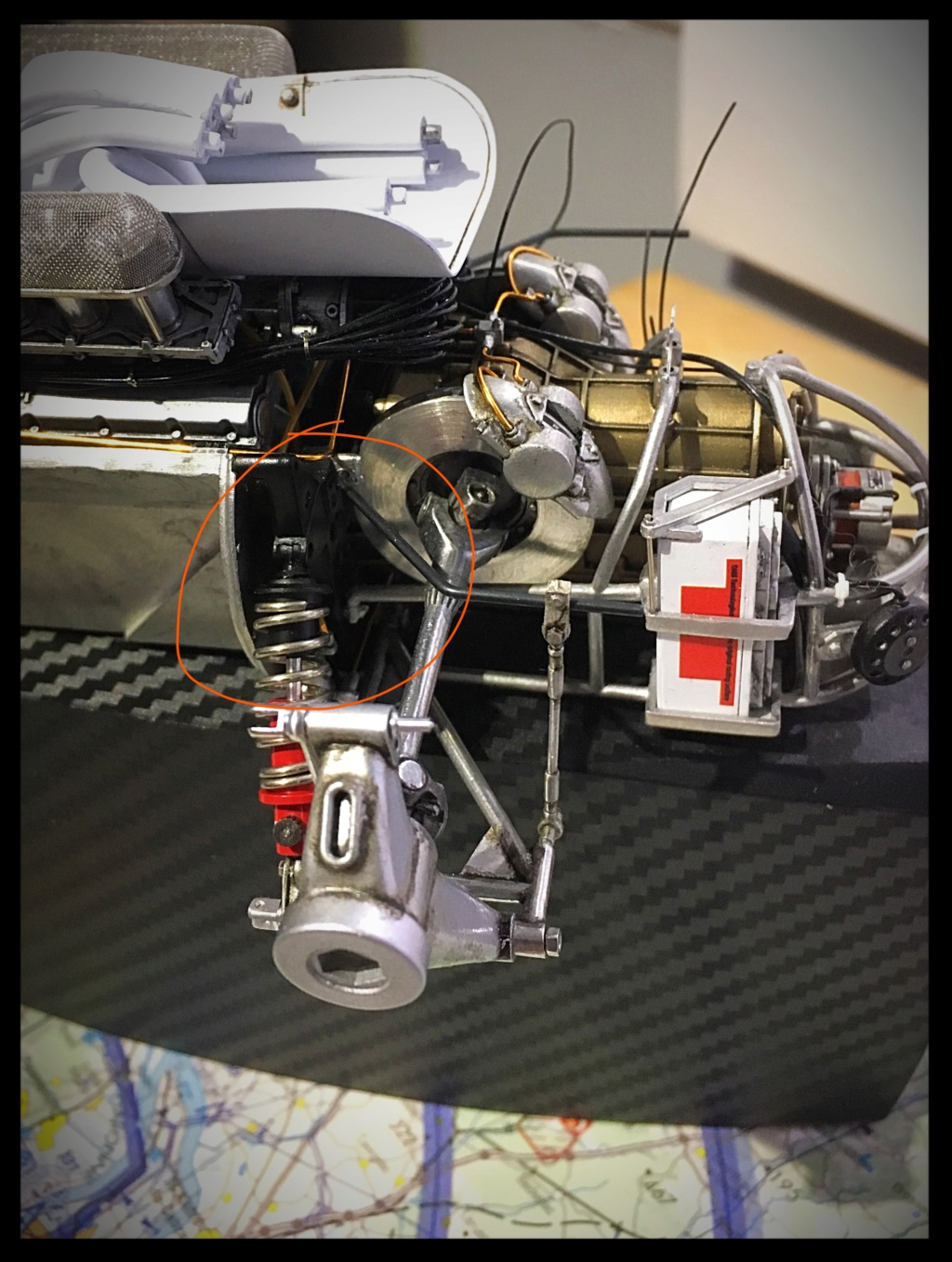

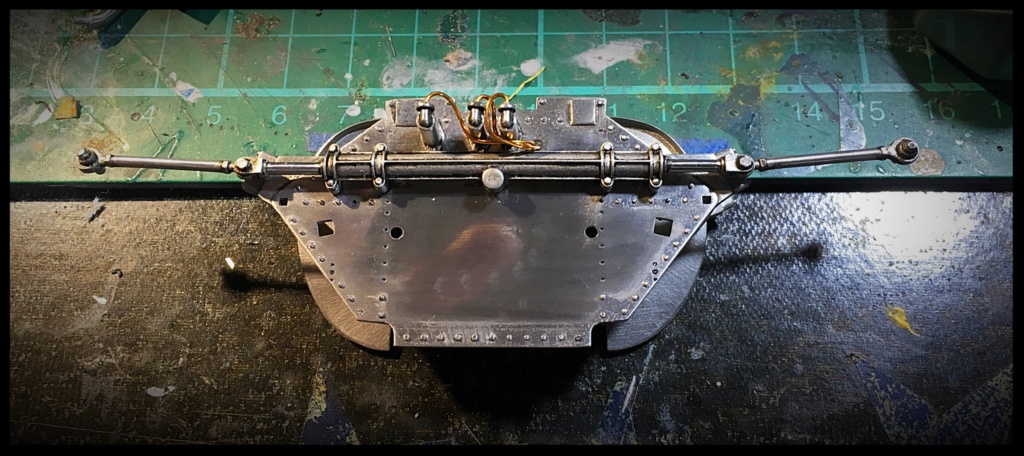

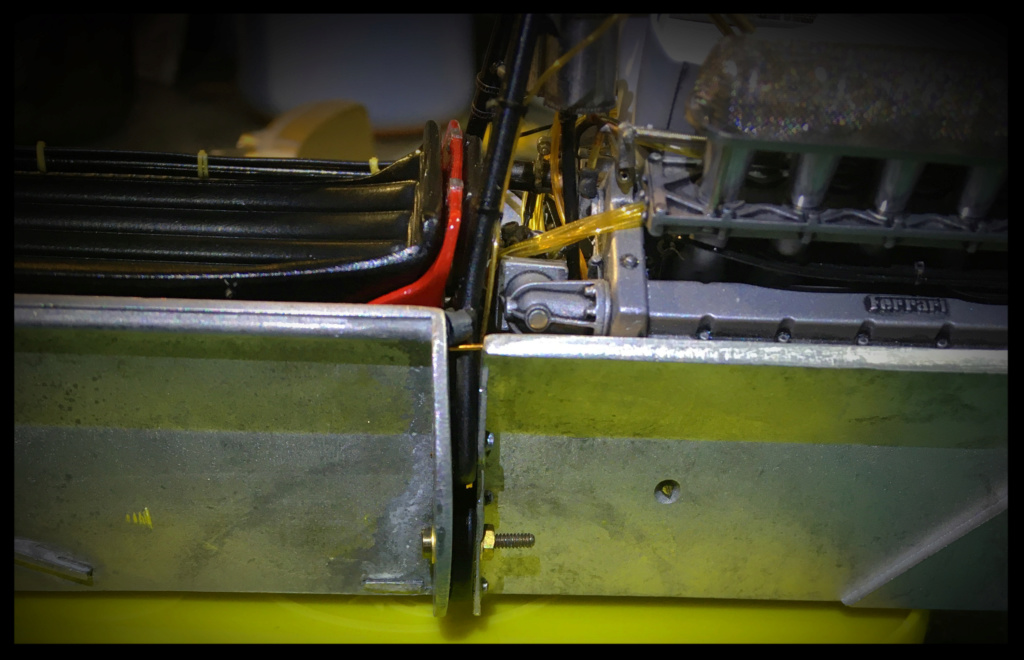

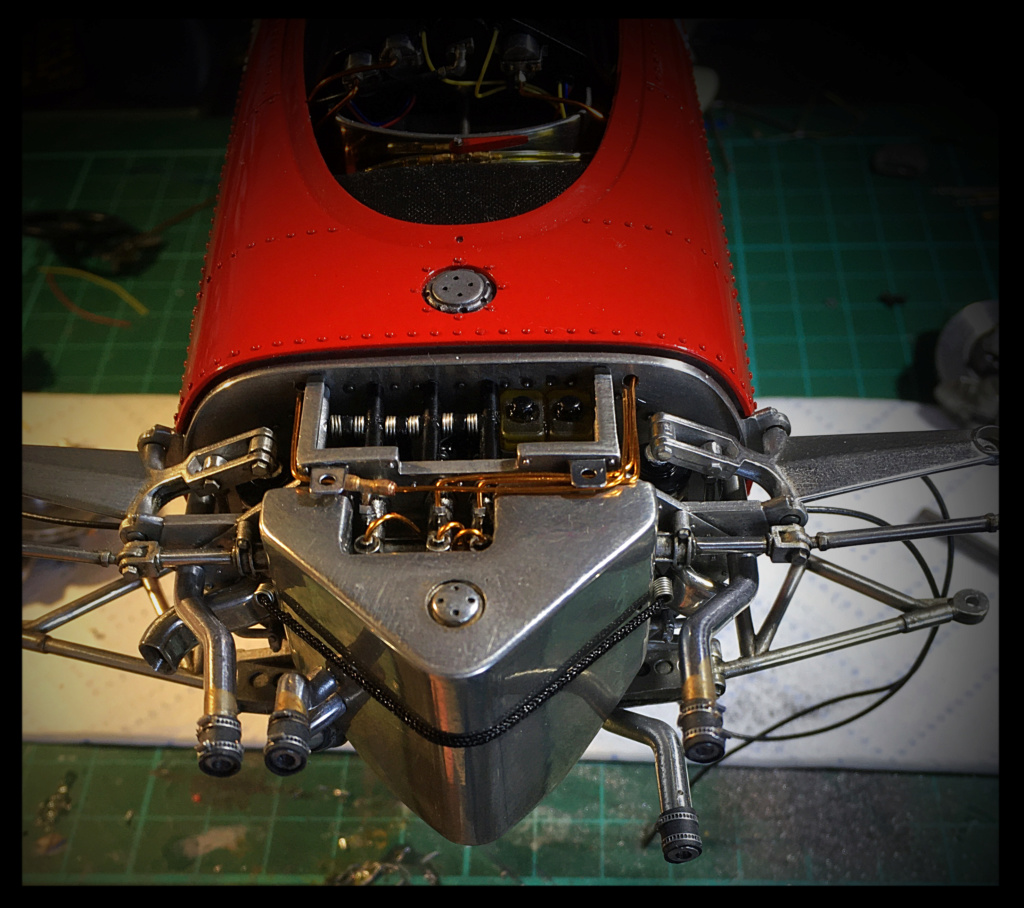

Test fit of anti roll bar, gearbox and half side transmission.

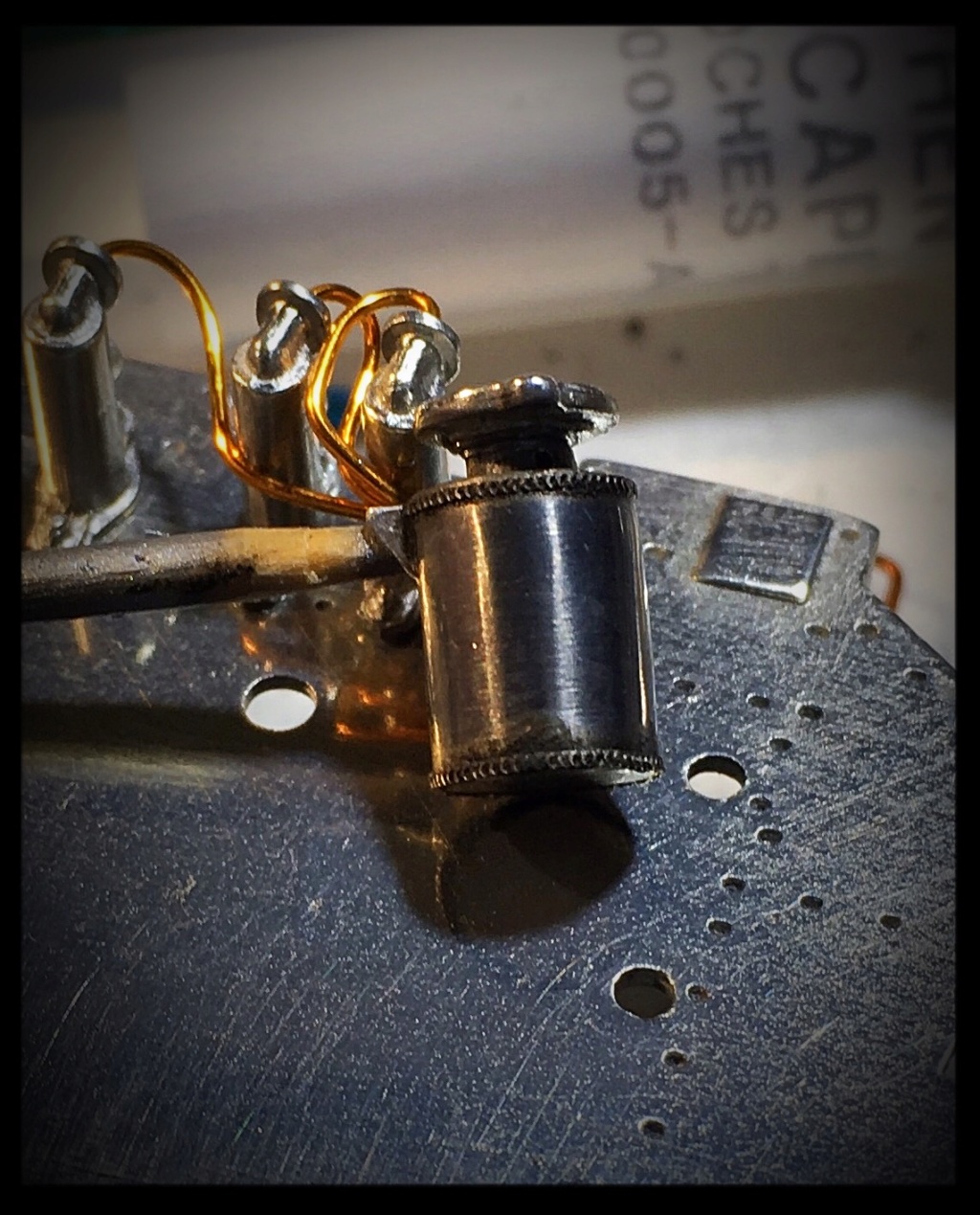

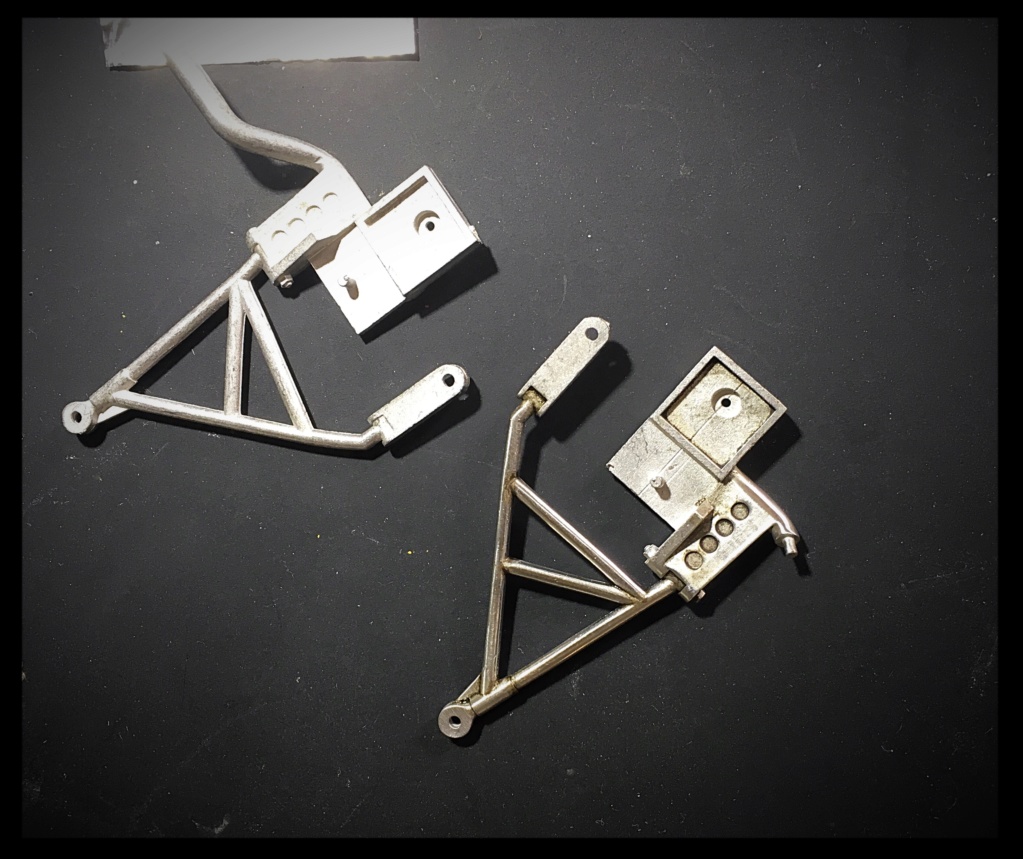

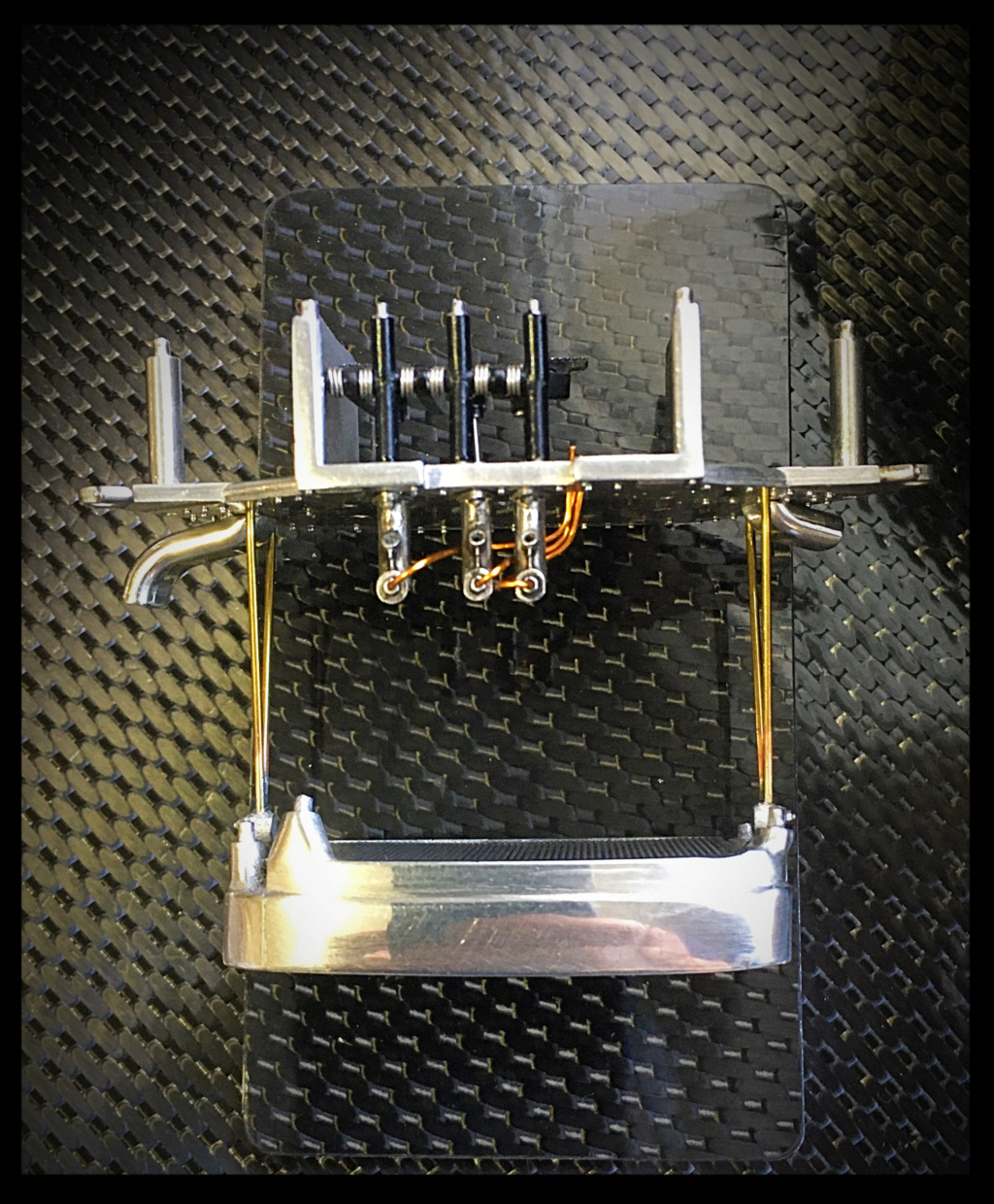

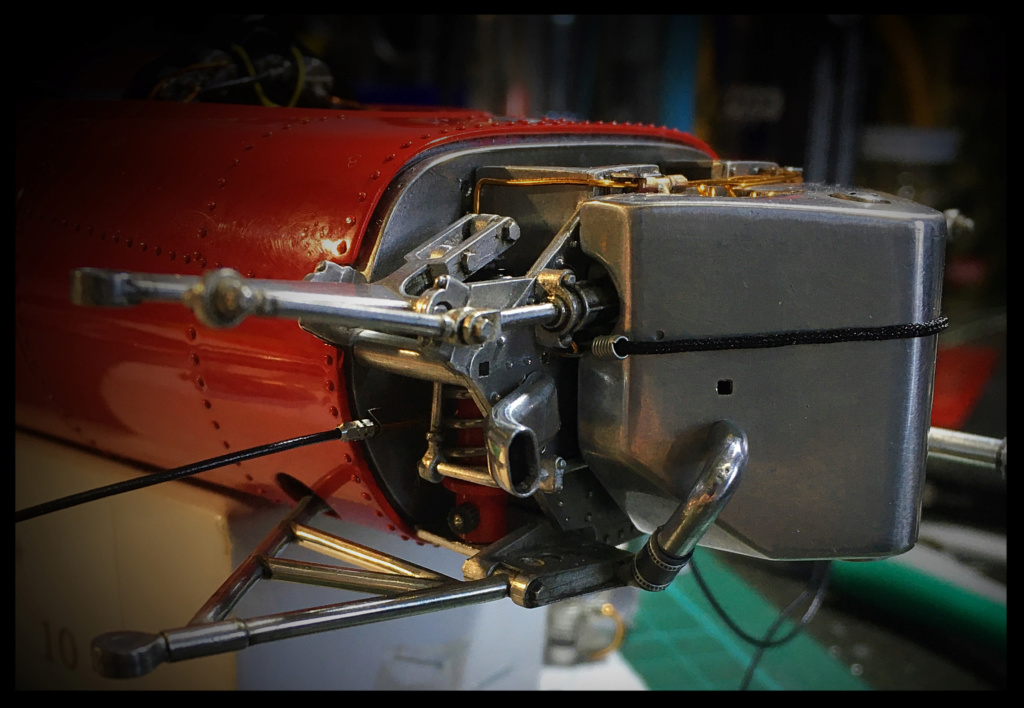

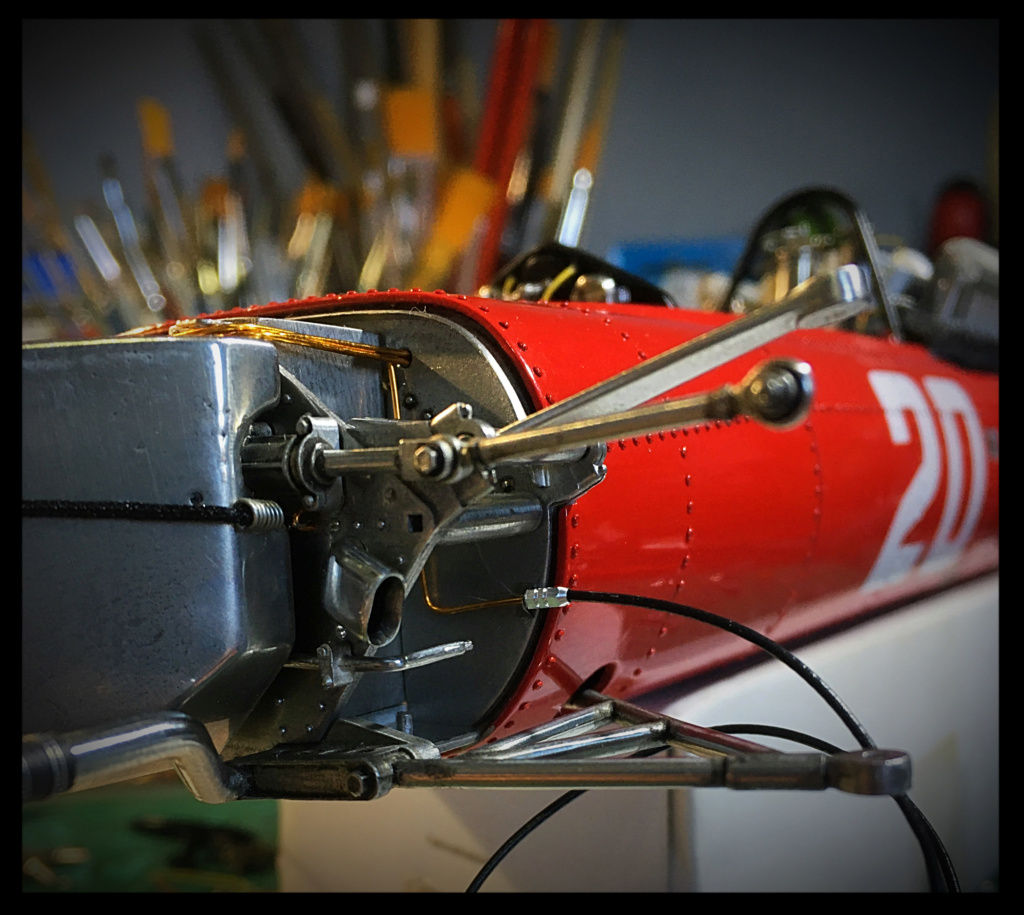

I’ve modified the throttle linkage.

The White Metal original ones were not that good, so I replaced them with machined parts.

https://i.servimg.com/u/f12/12/38/43/52/99c8dc10.jpg]

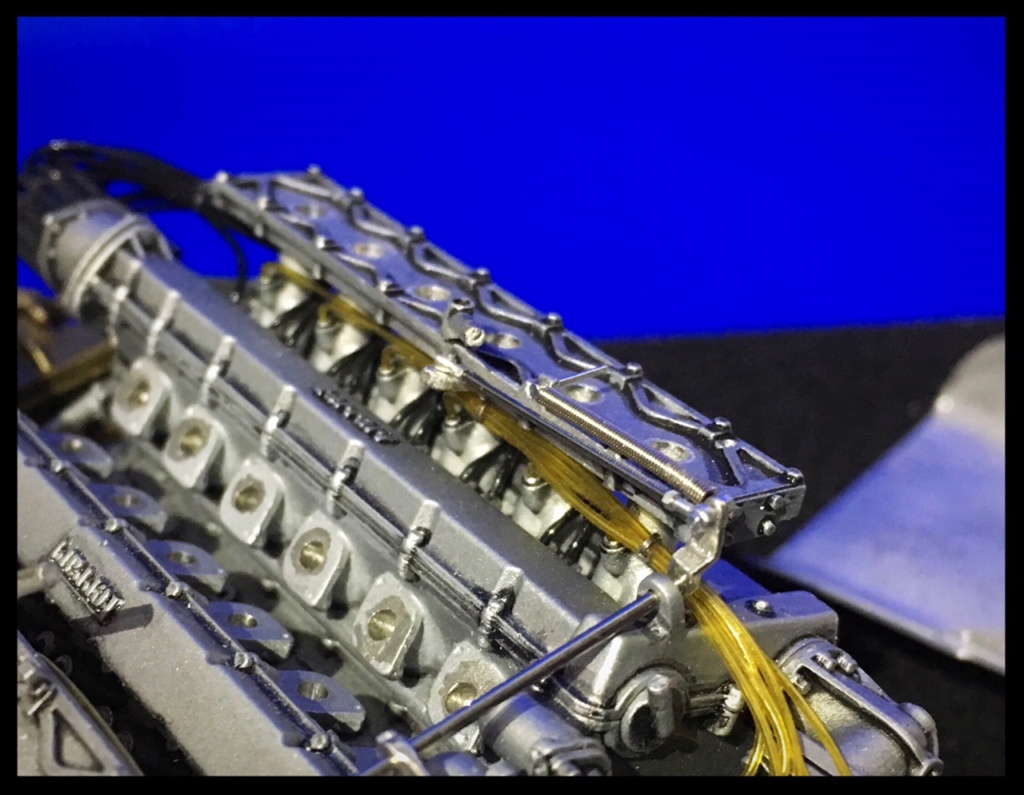

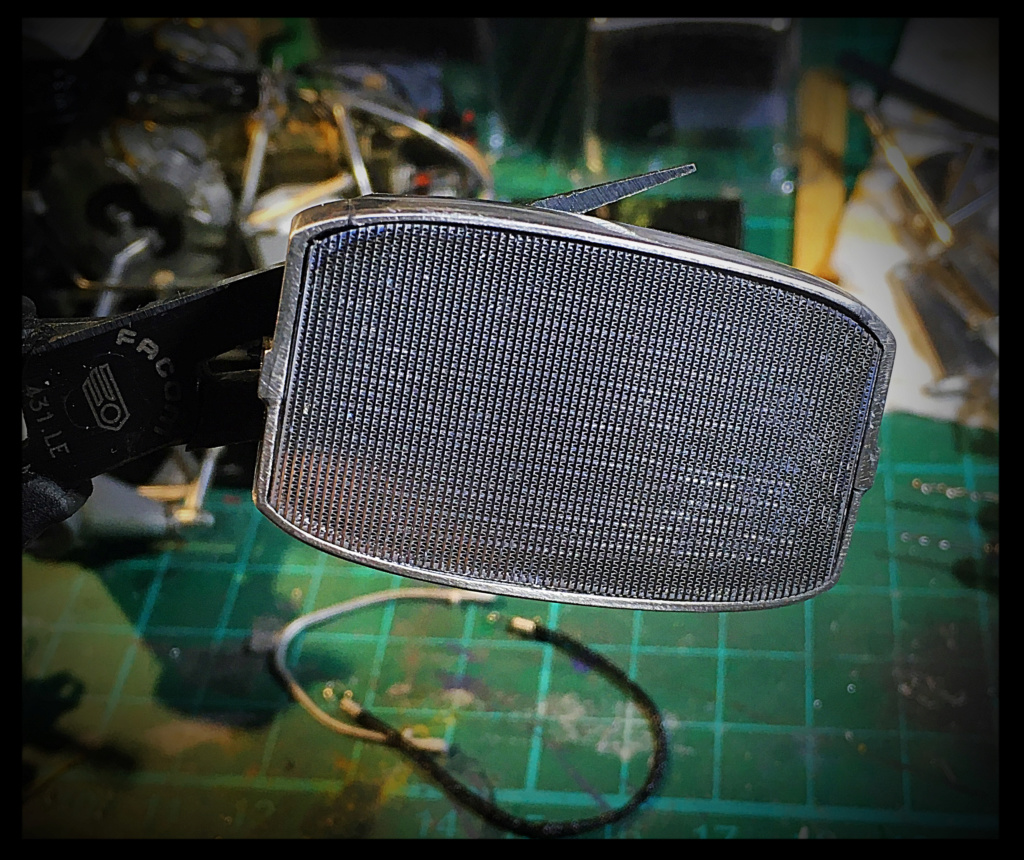

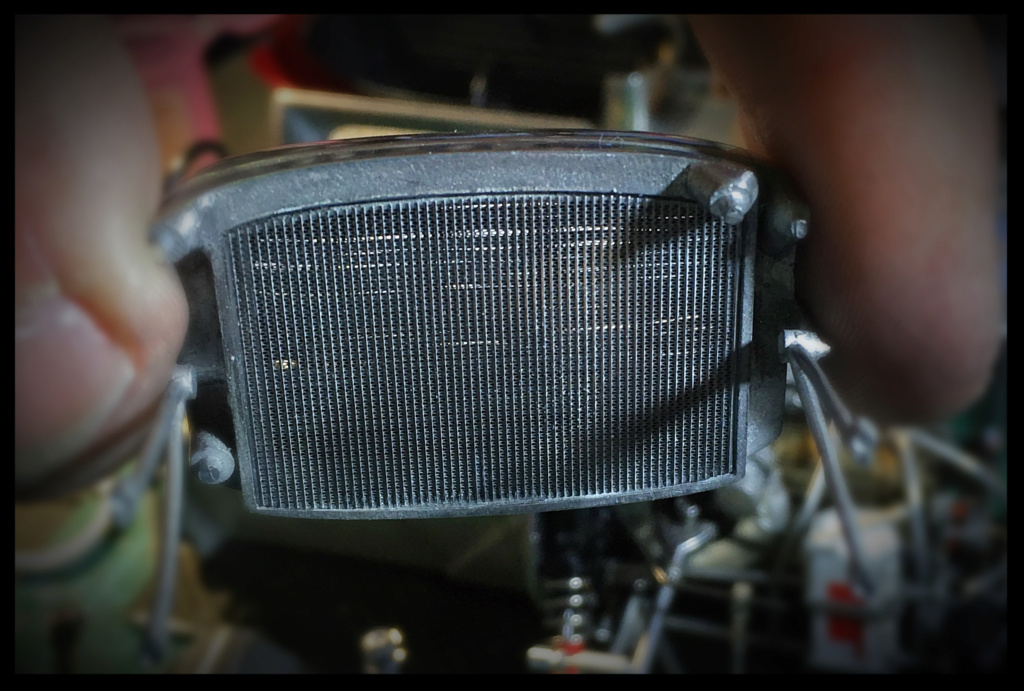

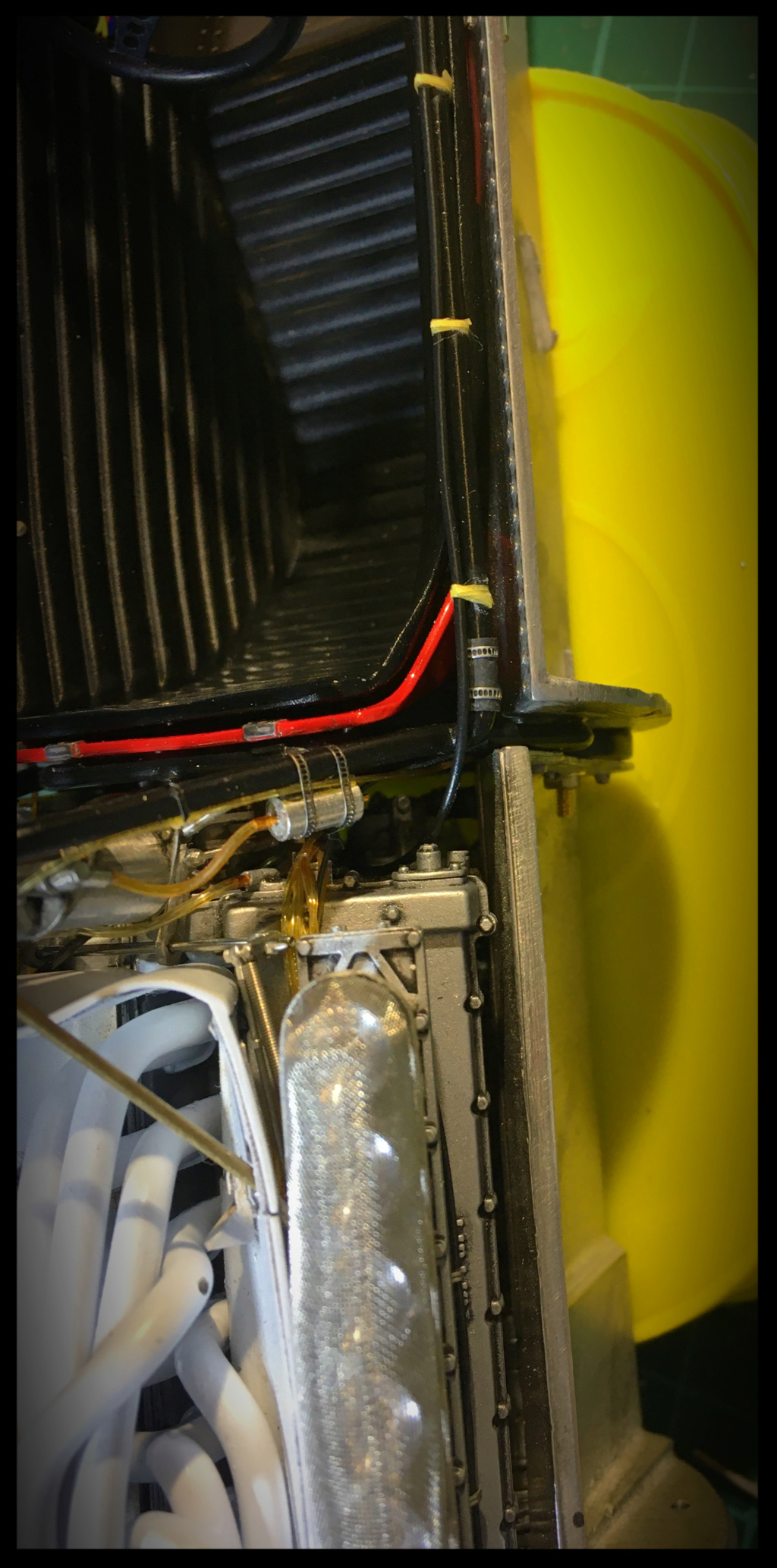

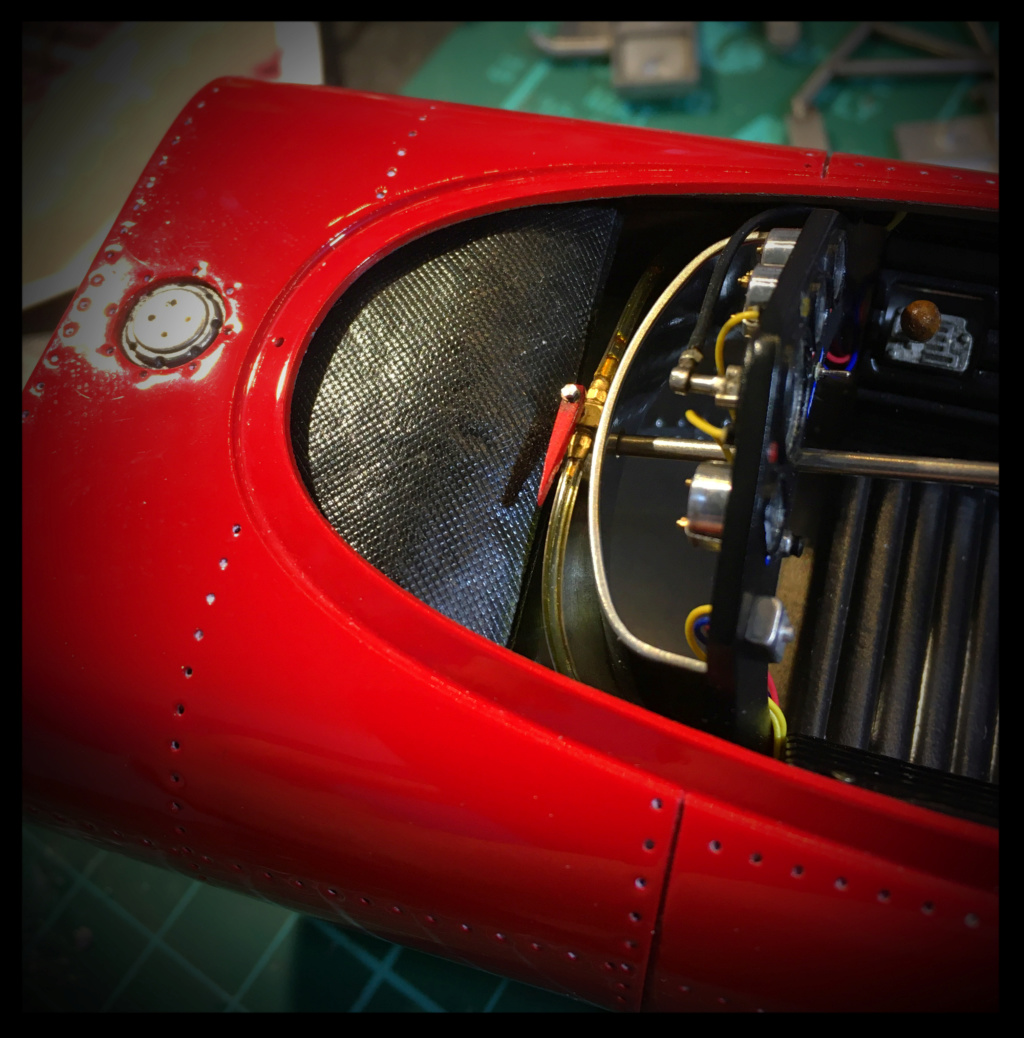

The mesh over the stacks is now done, and I must admit it was pretty fun to form and install: I’m mot unhappy with the result.

Oils have also been applied on the heat shield as well as a portion of aluminium tape on both external sides.

I really like the view of the trumpets through the mesh.

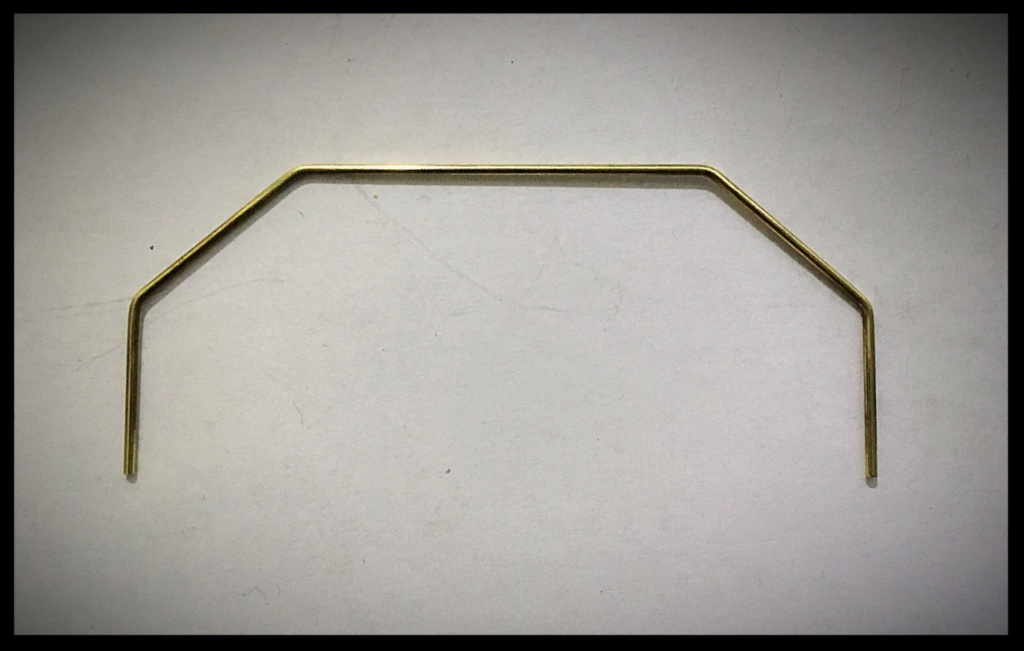

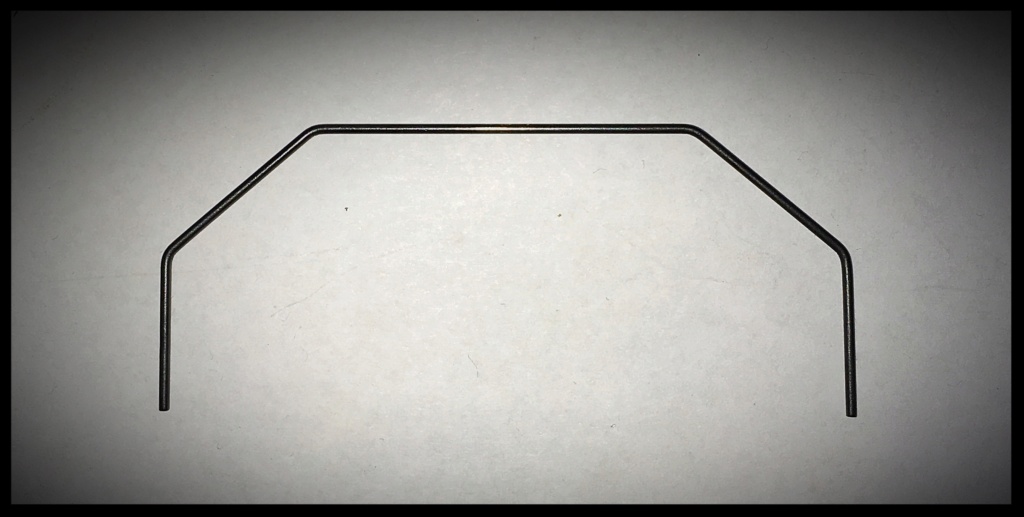

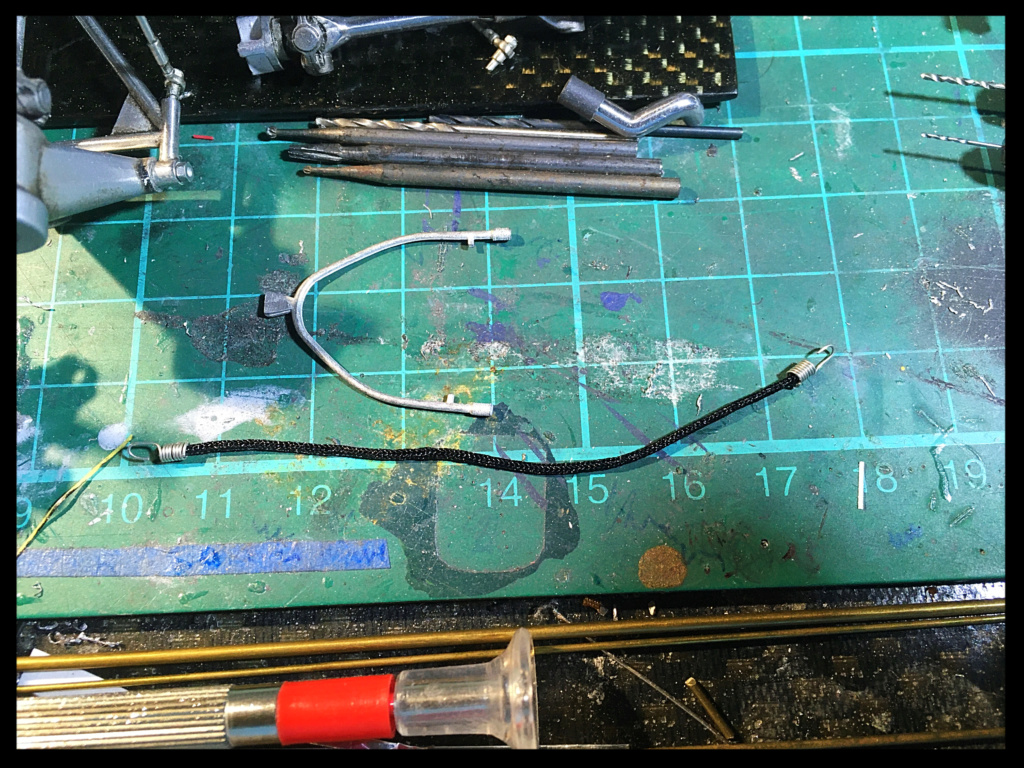

The rear stab bar has been remade with 1mm ø brass, which was later chemically burnished.

Now working on the connection rods.

One started comp#65279;ared to raw white metal origi#65279;na#65279;l part.

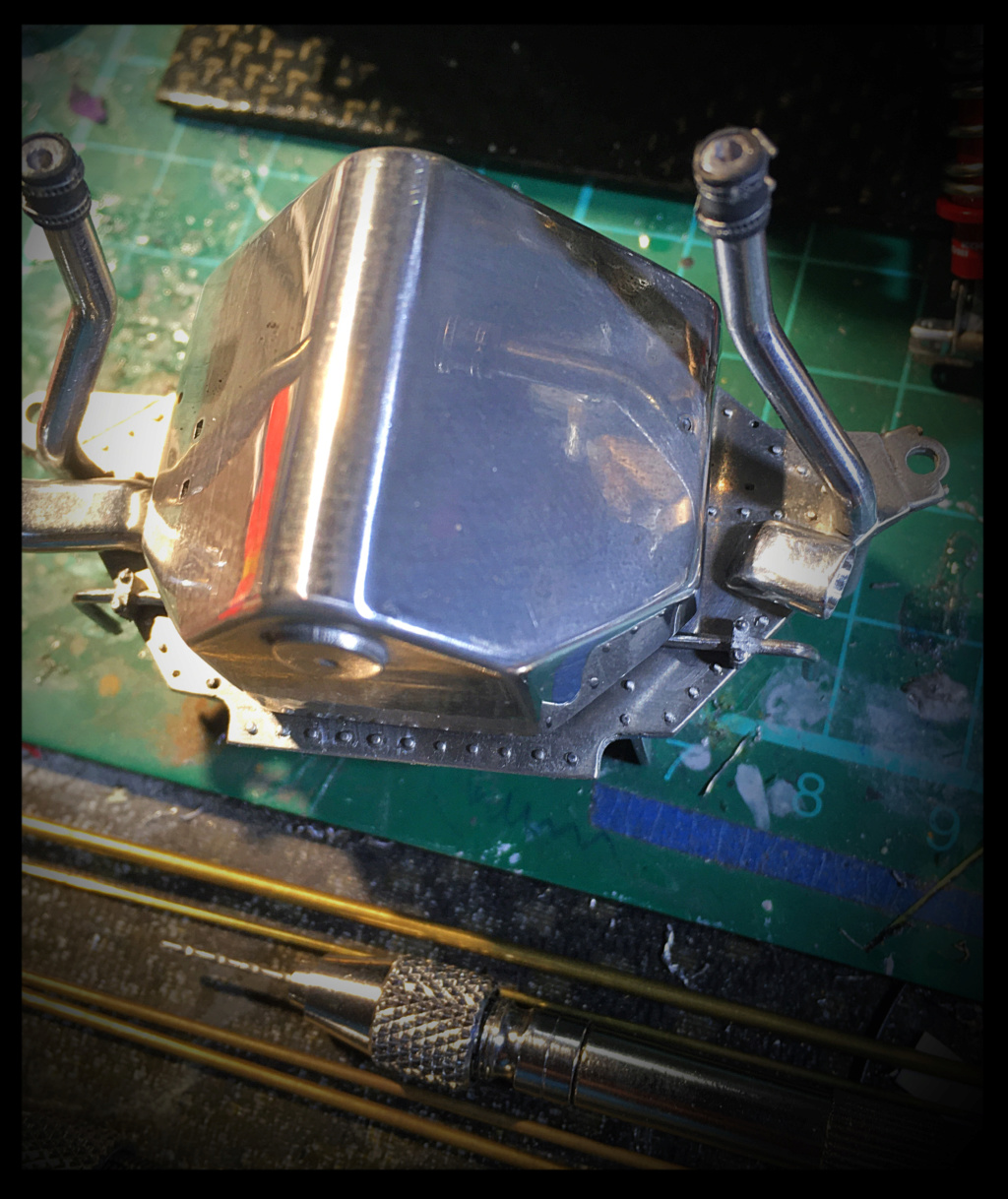

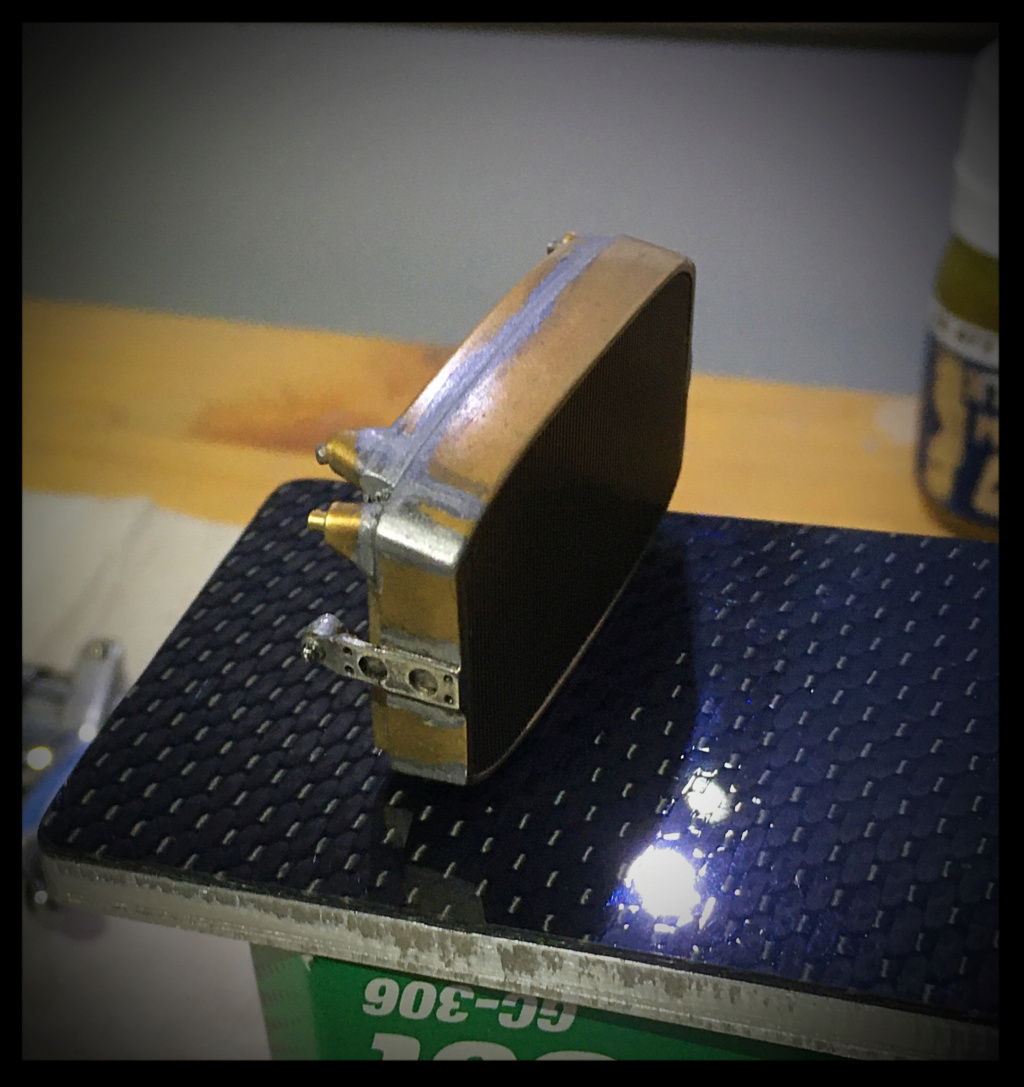

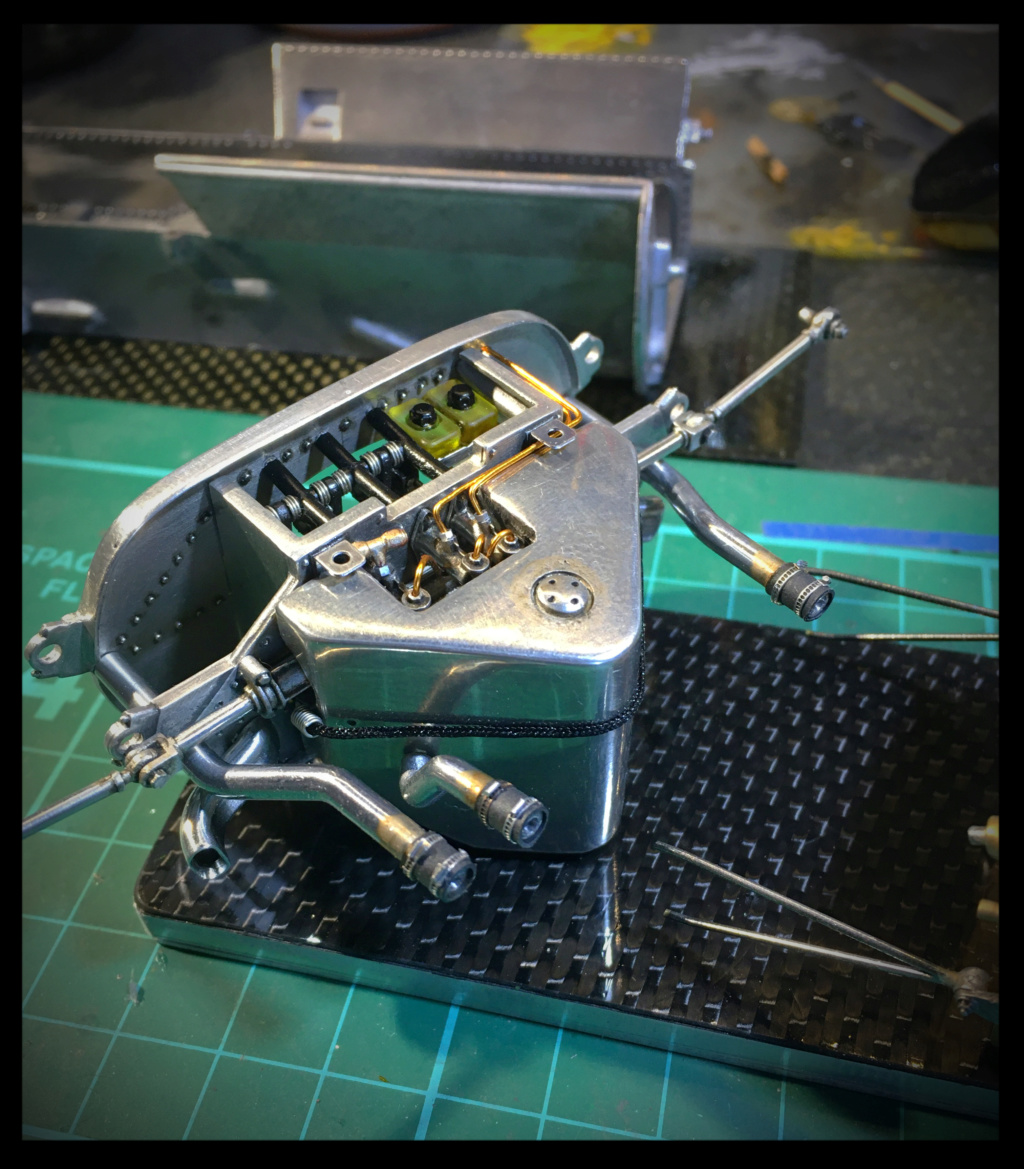

I worked a bit on the small metal tanks and others parts that need to be cleaned and polished.

Fuel filter/distributor and water expansion tank.

I also made a quick test of the pedals on the front bulkhead.

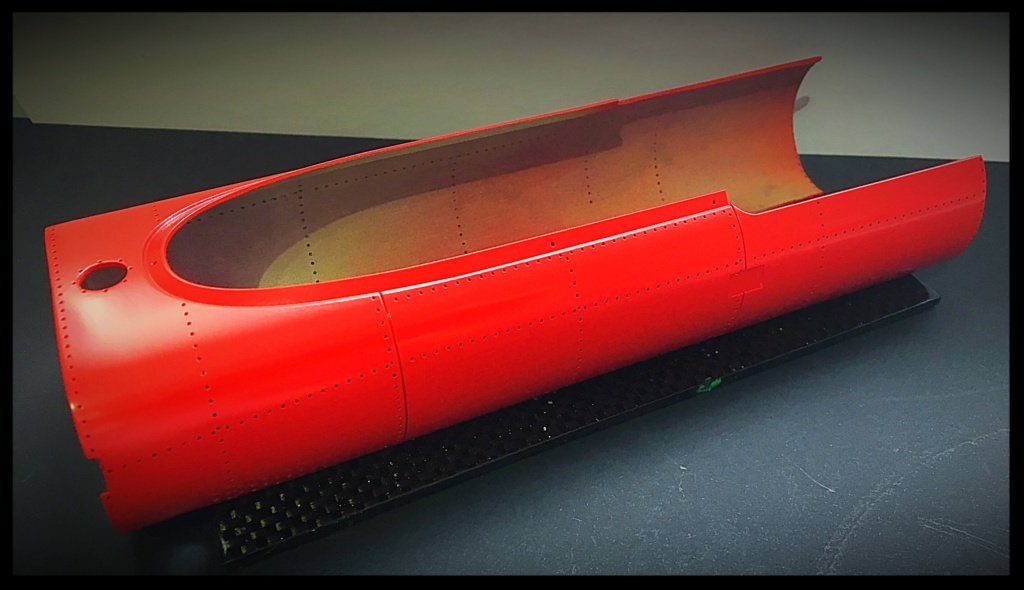

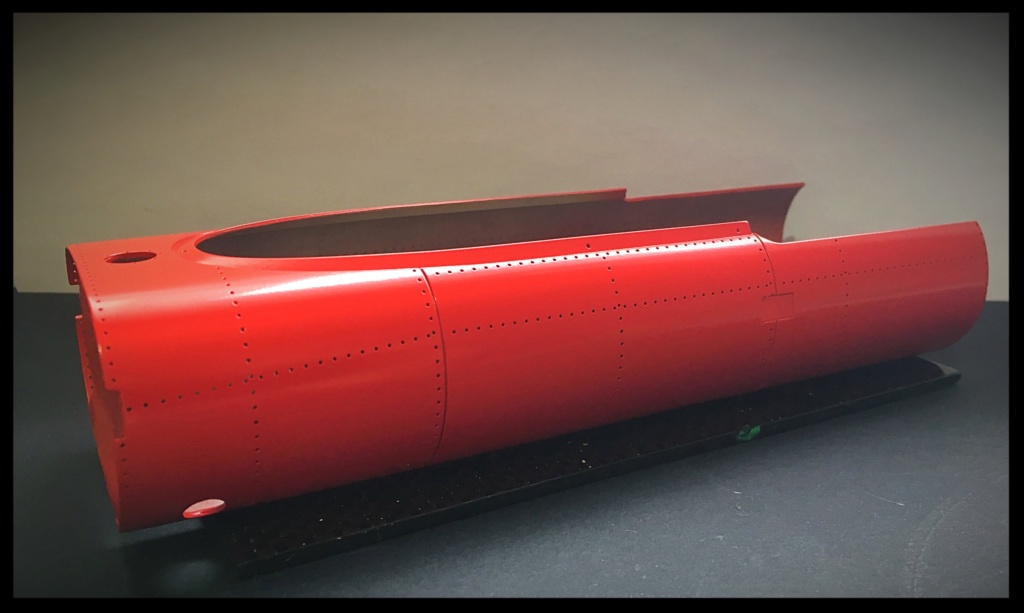

Test fit of the rear structure and tank of the Red Roaring Beauty.

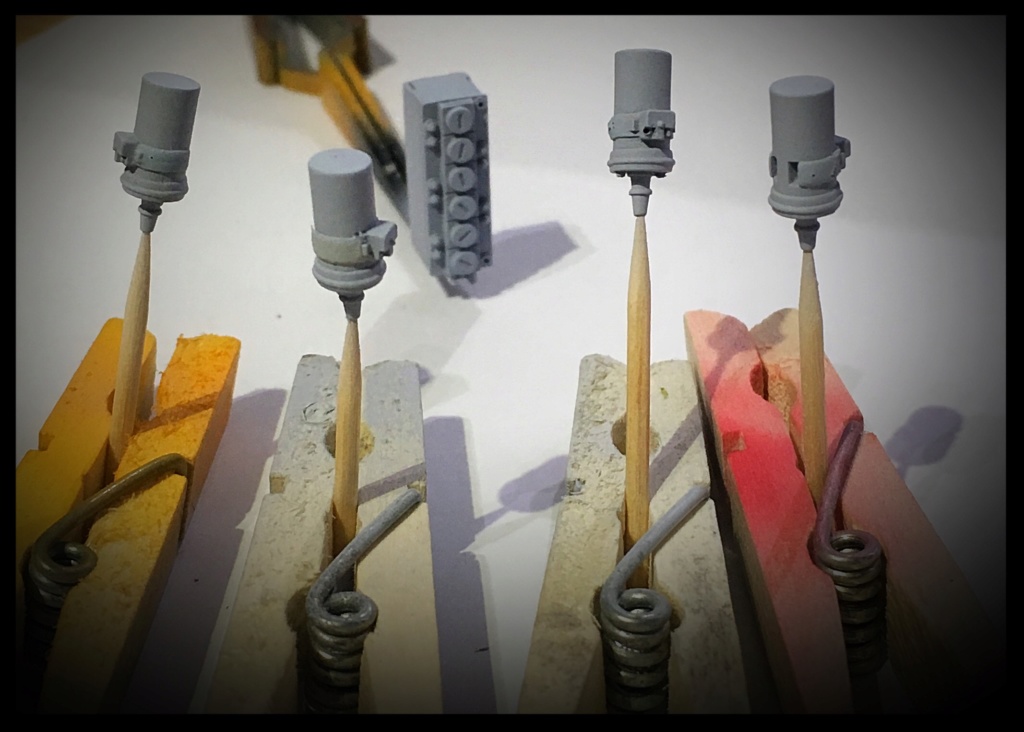

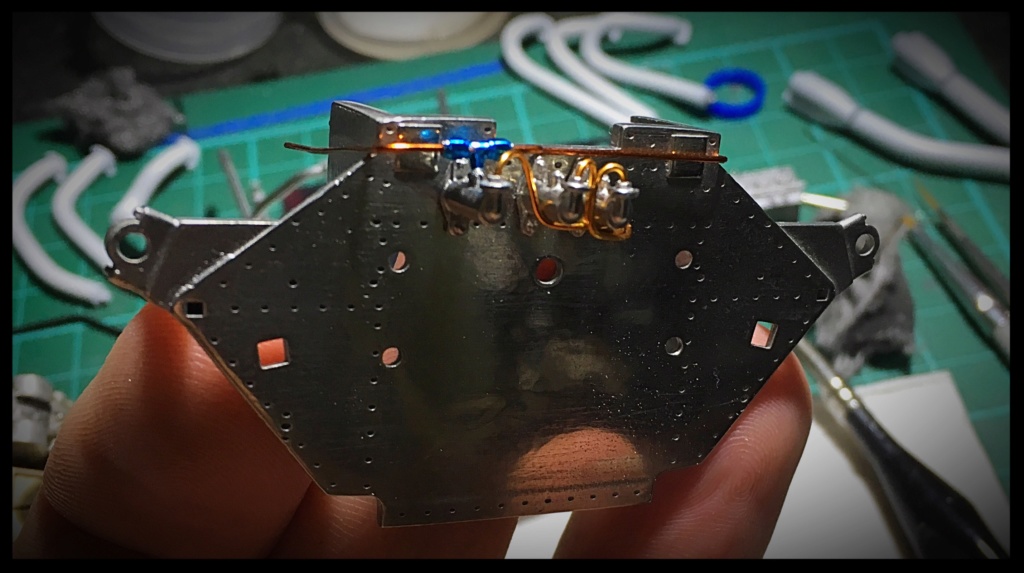

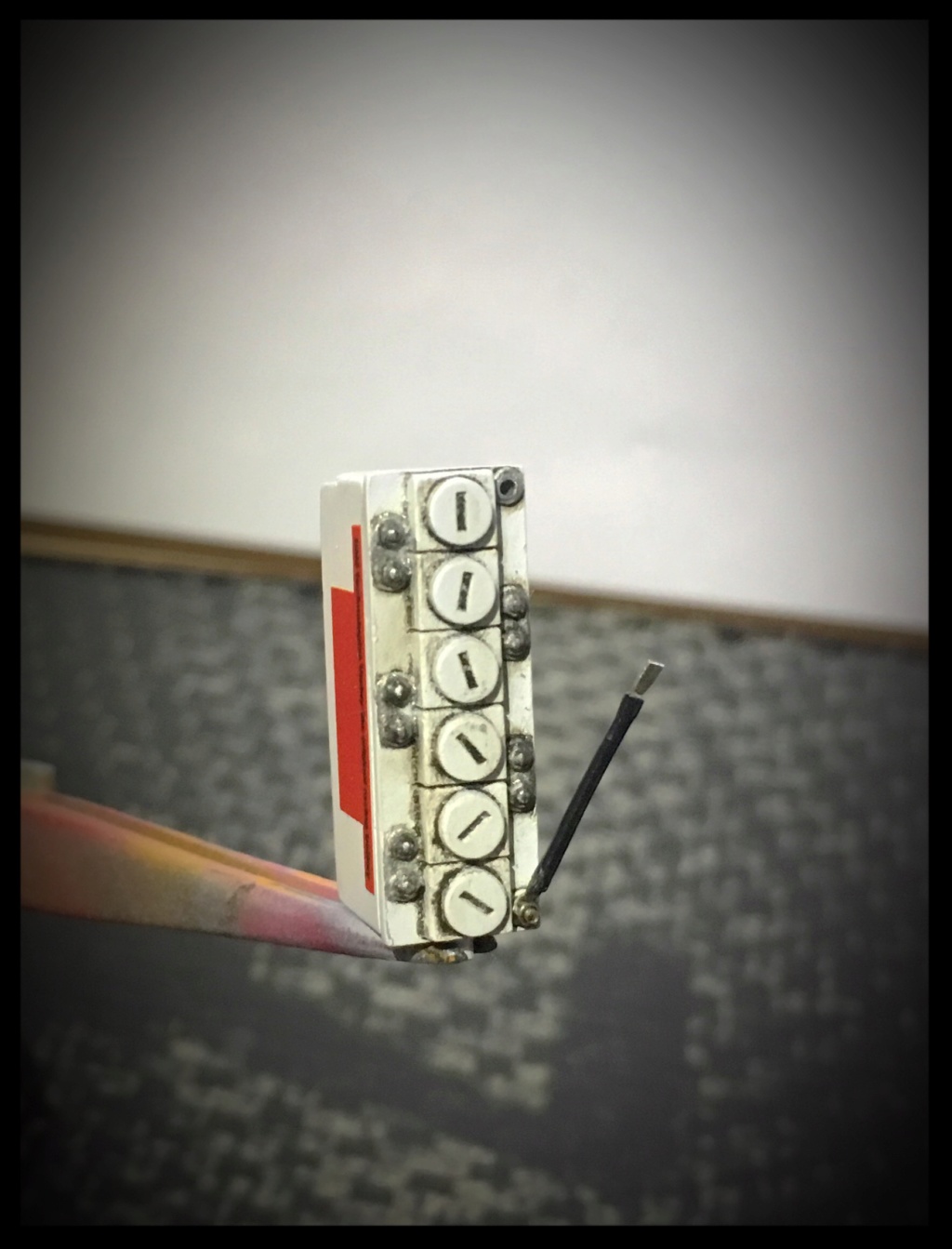

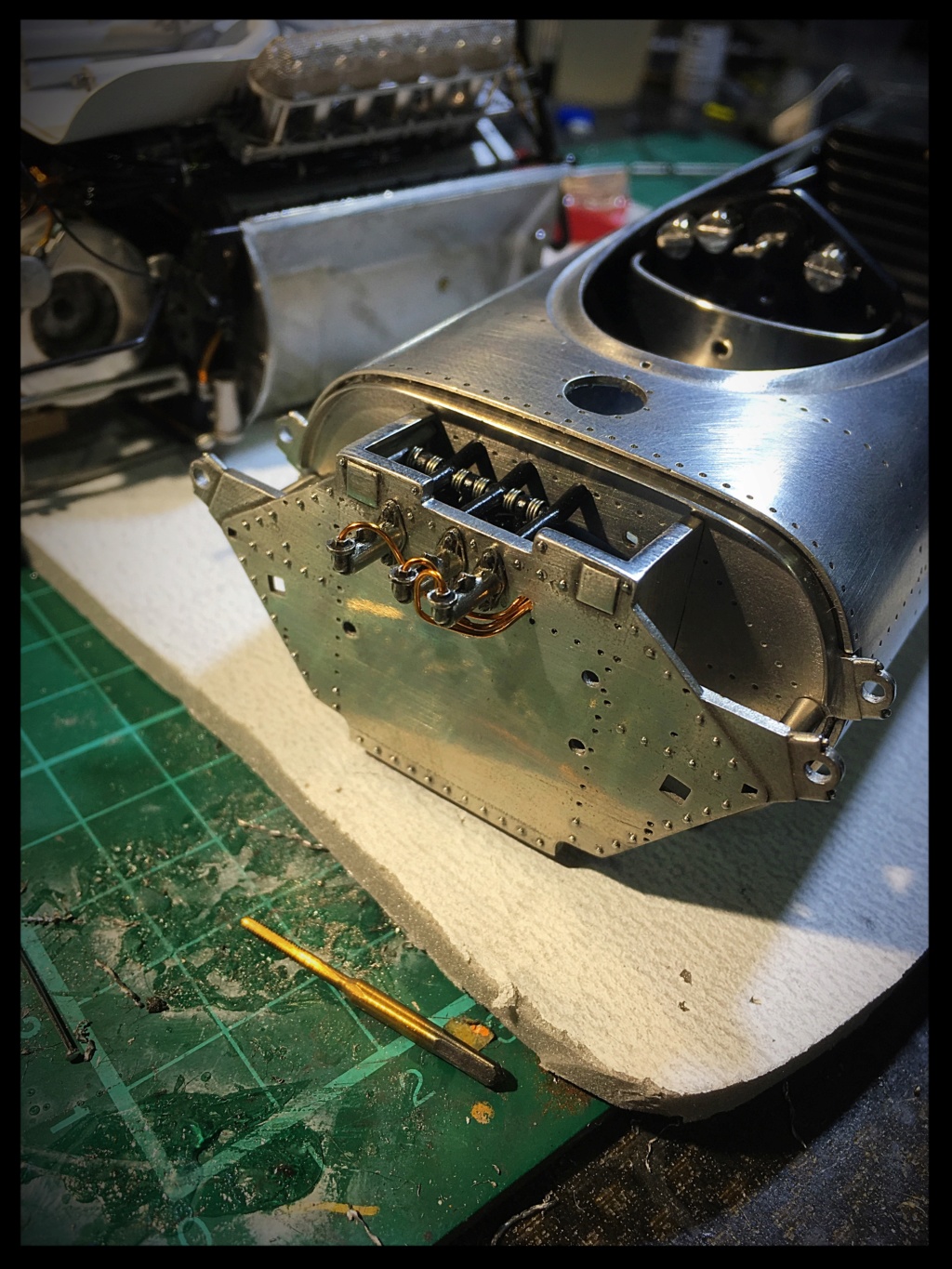

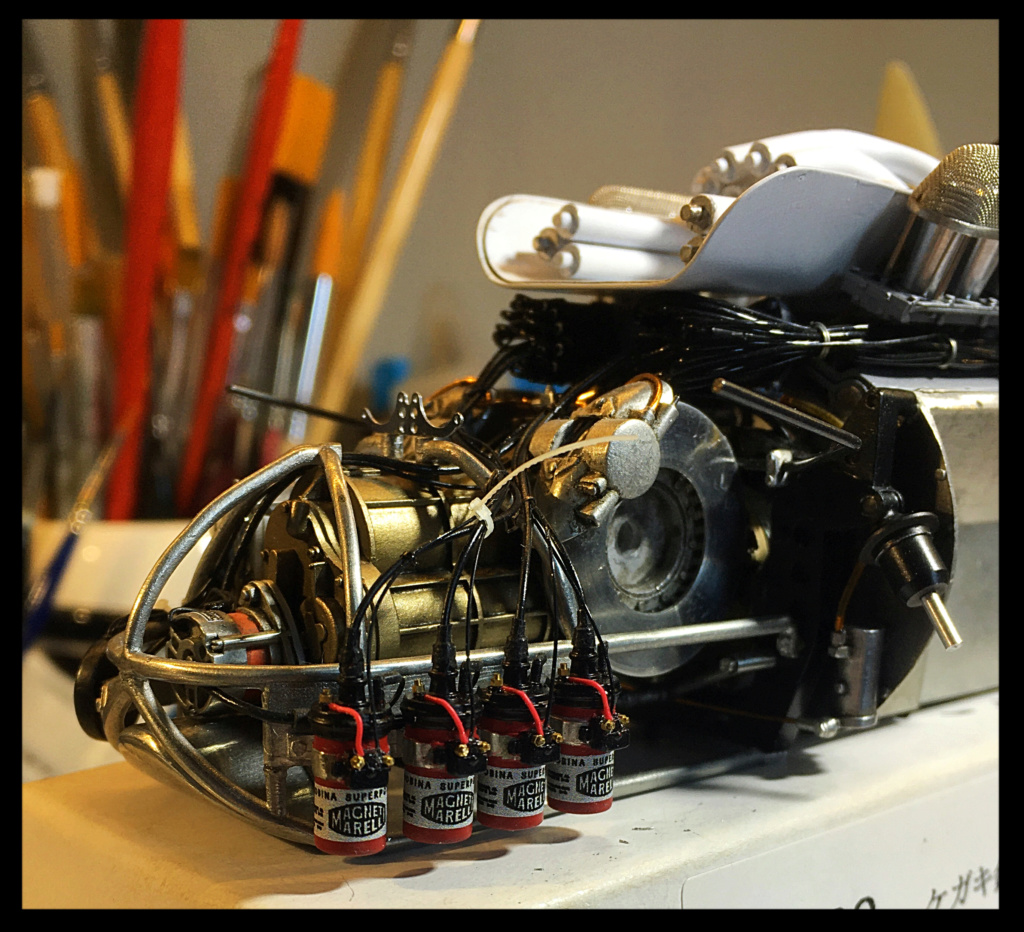

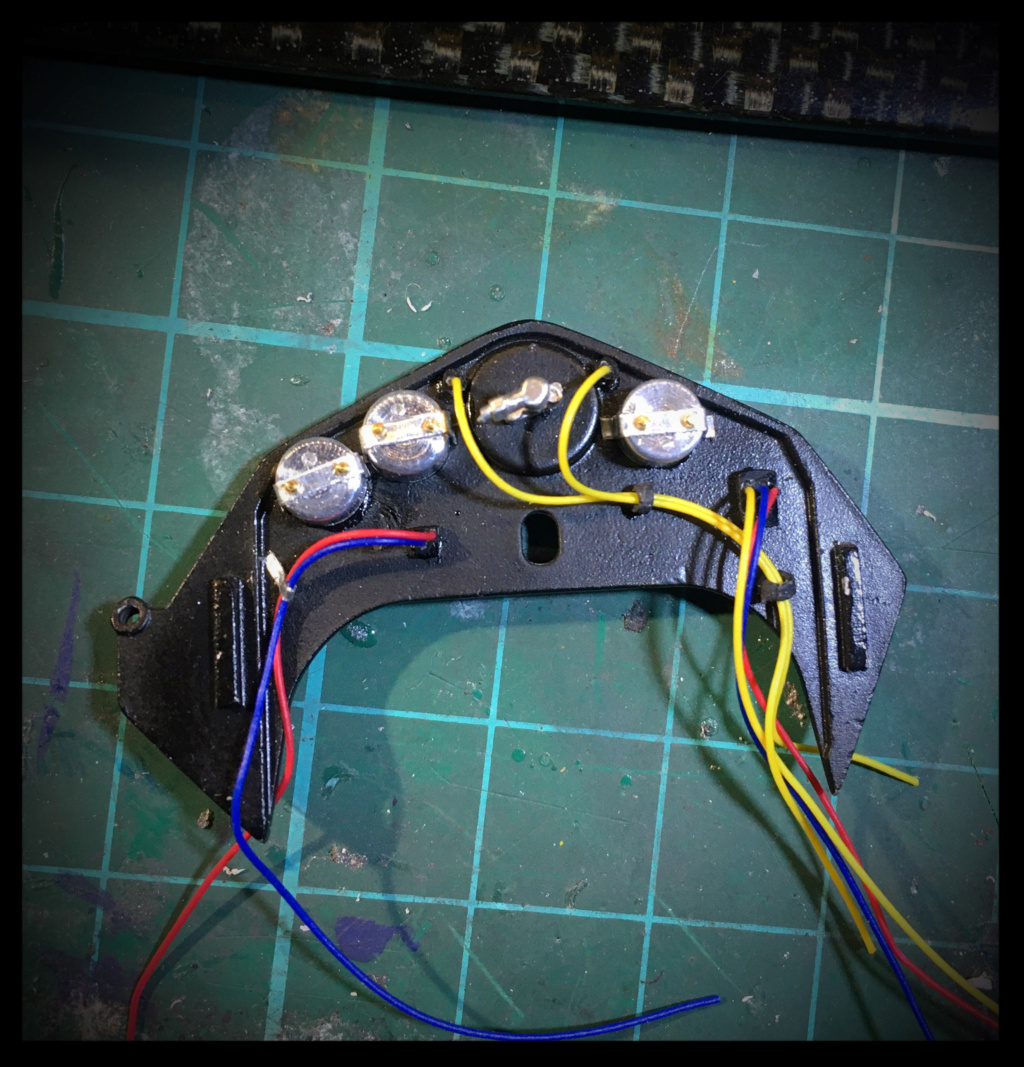

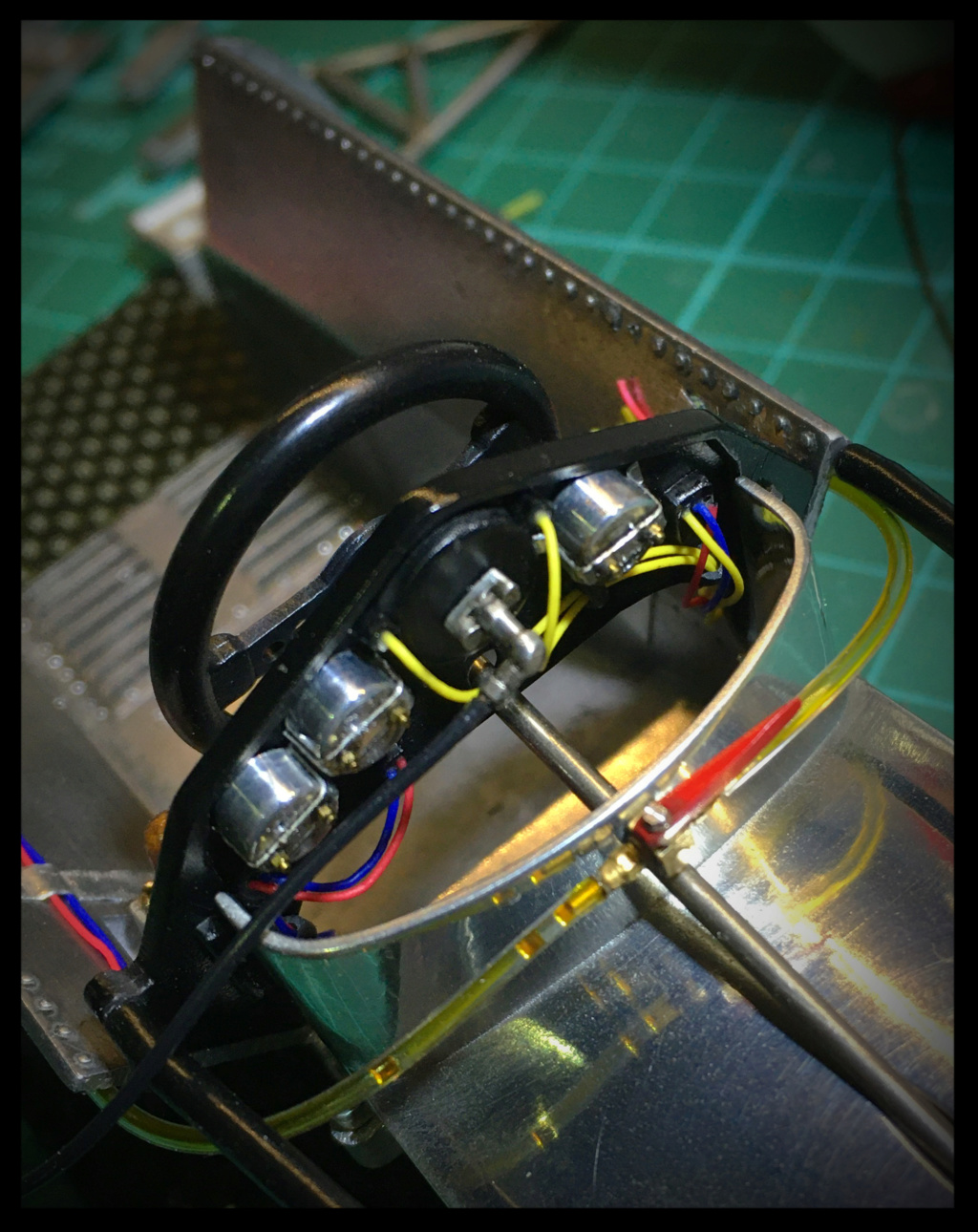

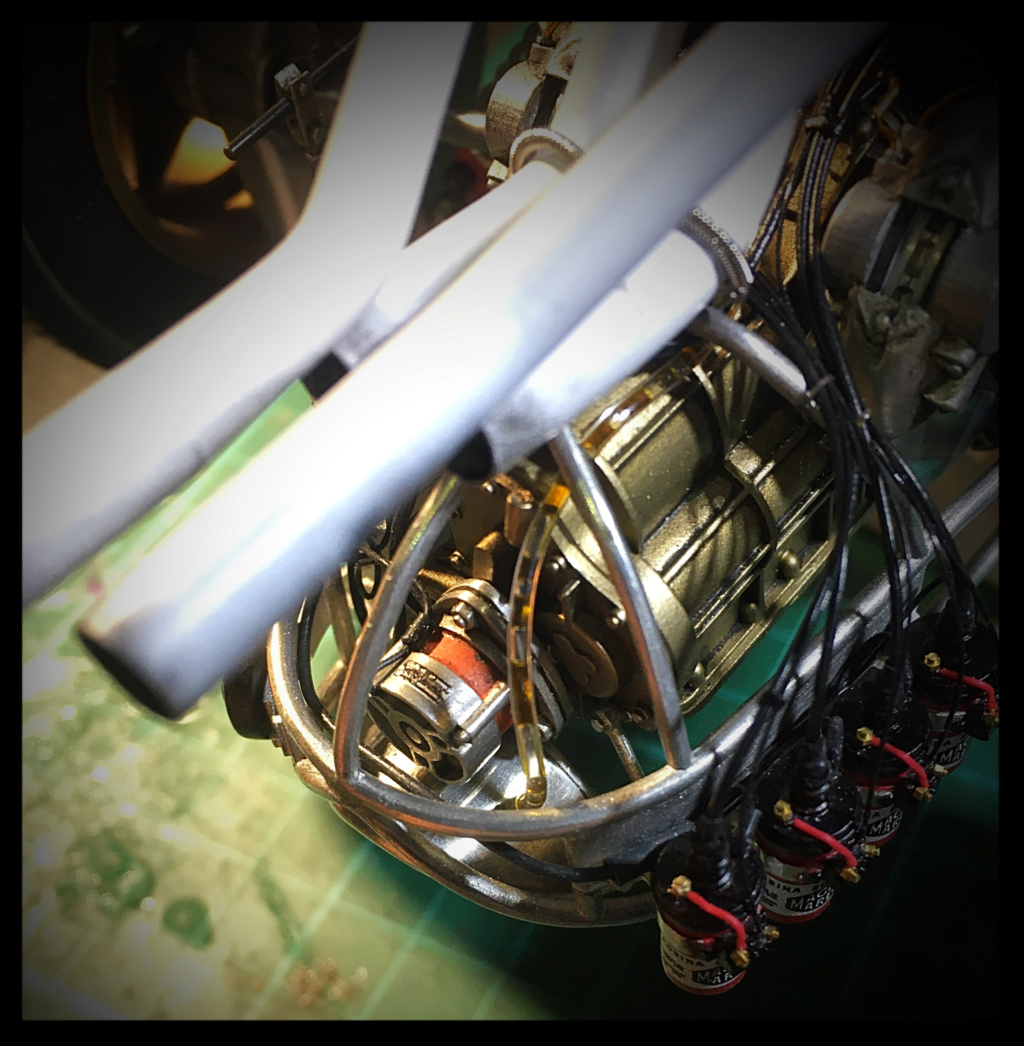

Battery and coils prepaired, masked and primed.

Starting to connecting brakes and fuel pipes.

Engine pan scratched.

Alfa Rosso ZP on the coils:

... And white (Titanium White GC) for the battery

Machined bolting and washers have been installed on the wheels.

An old « T » connector is modified and used to complete the front wheels brakes master cylinder.

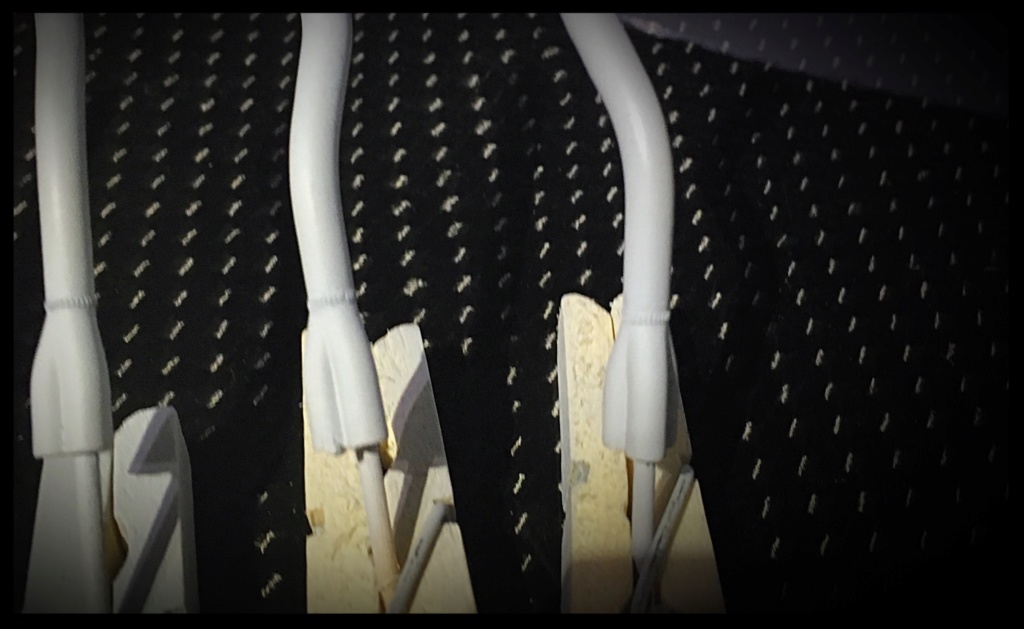

Tanks and tubes installed on the roll bar with serflex & Ty-Raps:

Wires ready and waiting for the battery:

Started to work on the coils:

Sanding, welding, riveting...

https://i.servimg.com/u/f62/12/38/43/52/2b3e6810.jpg[/img

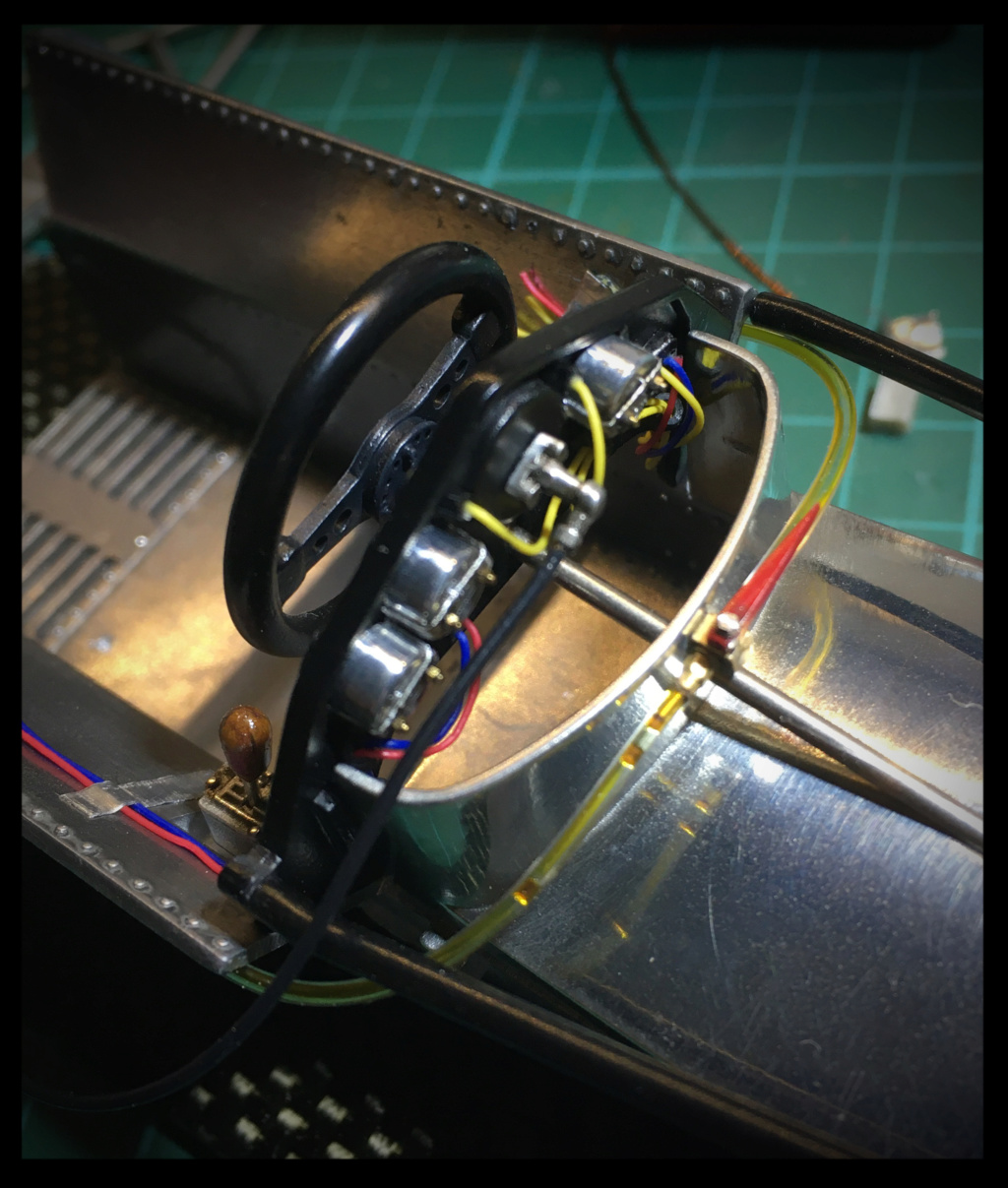

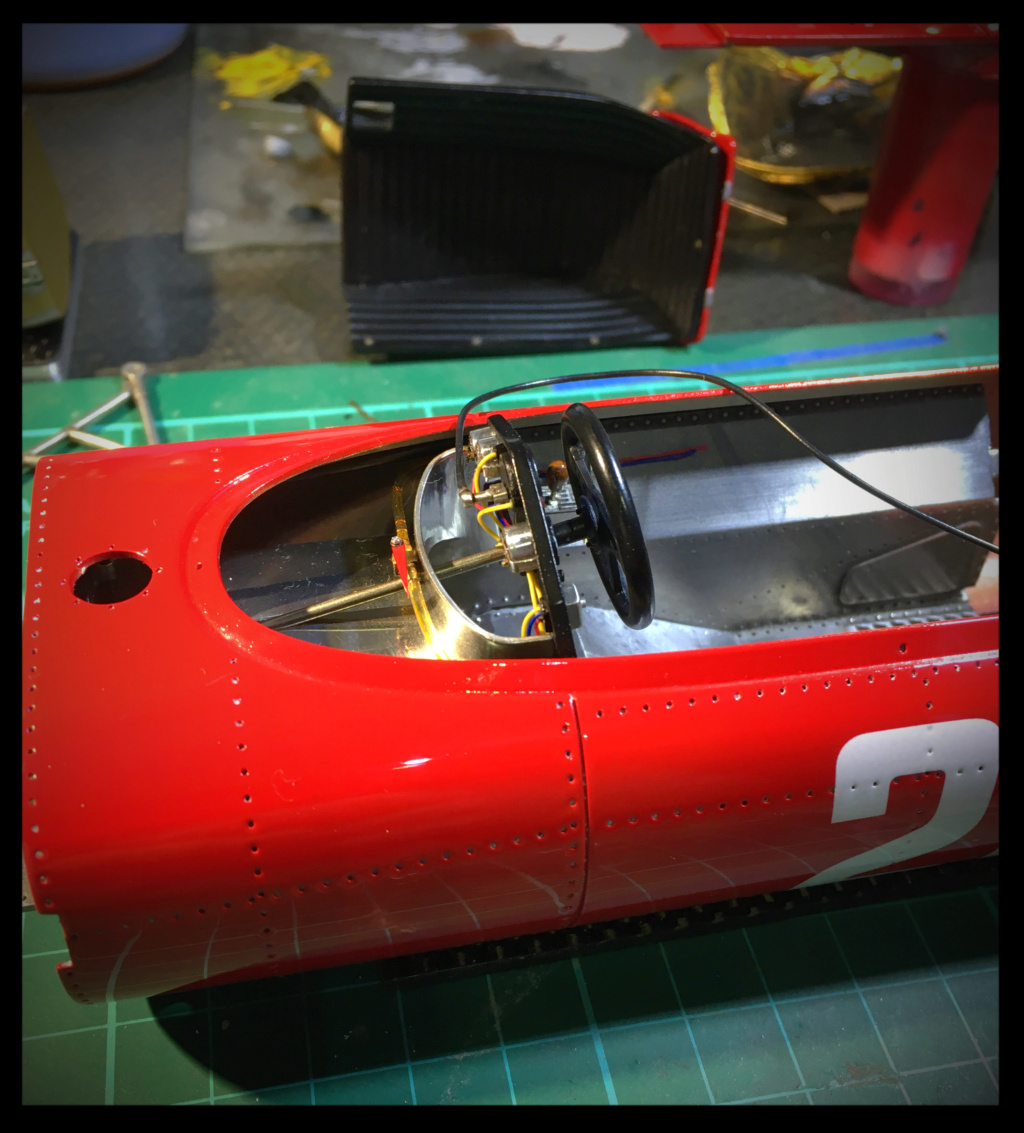

And, at least, progress in the “office” area:

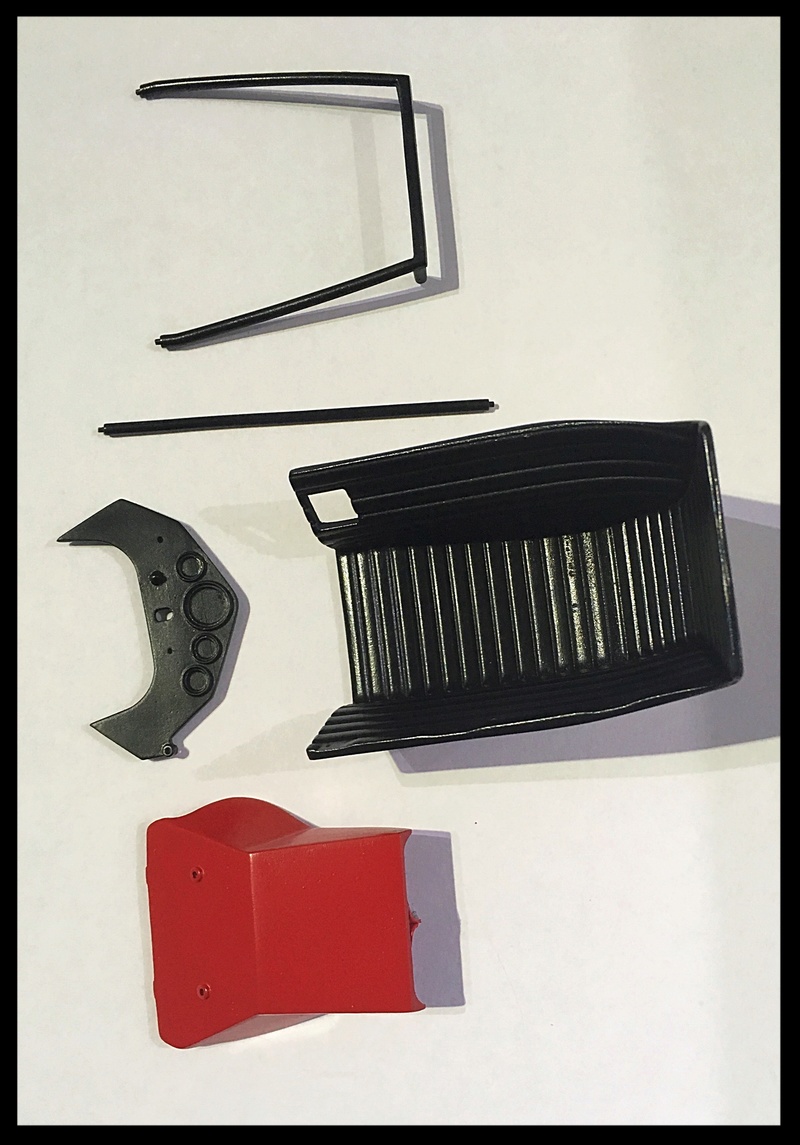

Paint session, dashboard session and gear lever/selector.

I was not that happy with the instruments, so I turned new ones and made brackets from aluminium foil.

Then test fitting.

Oils and screws added on the steering wheel and, of course, the Cavallino Rampante!

Riveting the bathtub and the bulkhead is now done.

The wooden shifter knob is clear coated and test fitting is mandatory for the engine/cockpit/body subassembly.

The fitting holes and the front Ferrari logo area are masked.

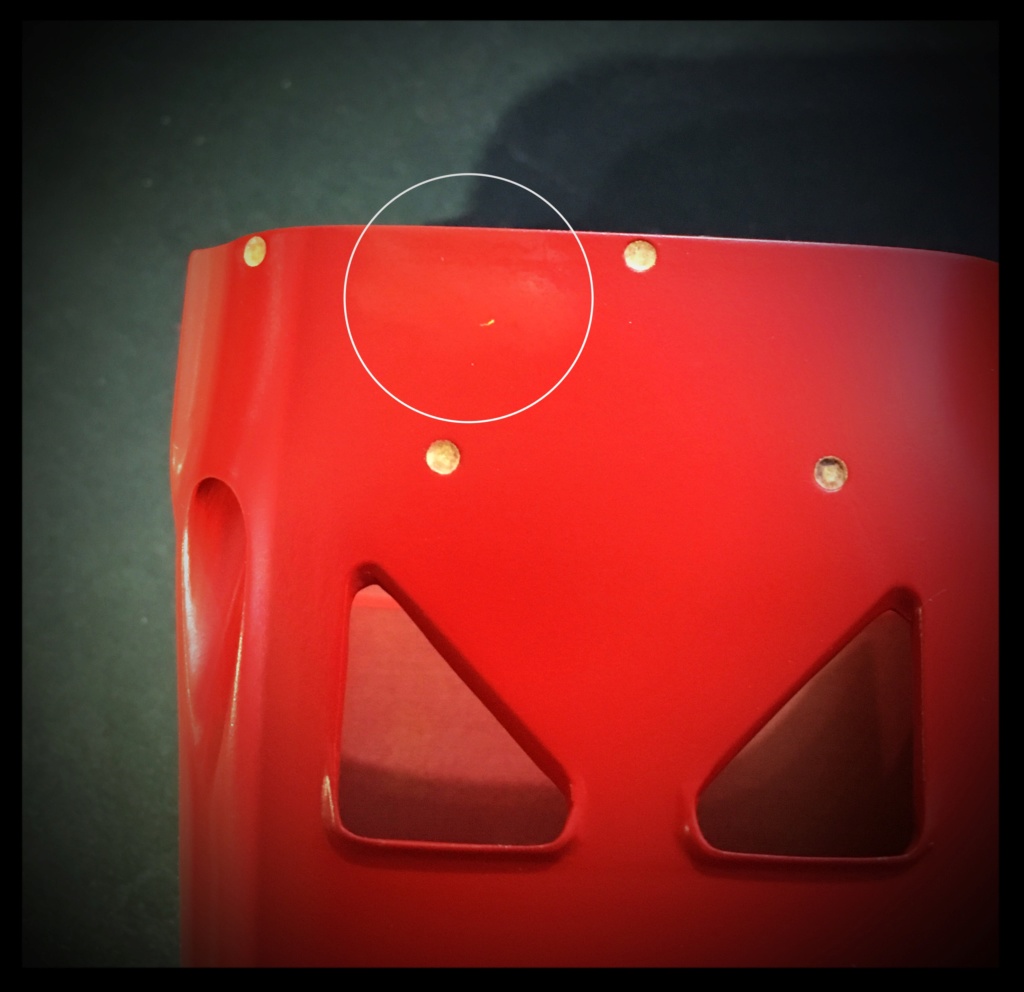

I had a little « spot » on the Red, so I sanded it and made a touch up.

The dampers looked to simple for my taste.

I used modified F1 Specialties brass electronic connectors and chemically burnished them, then put a center adjustment screw and finally install the knob on the damper.

A Koni decal add a nice looking detail.

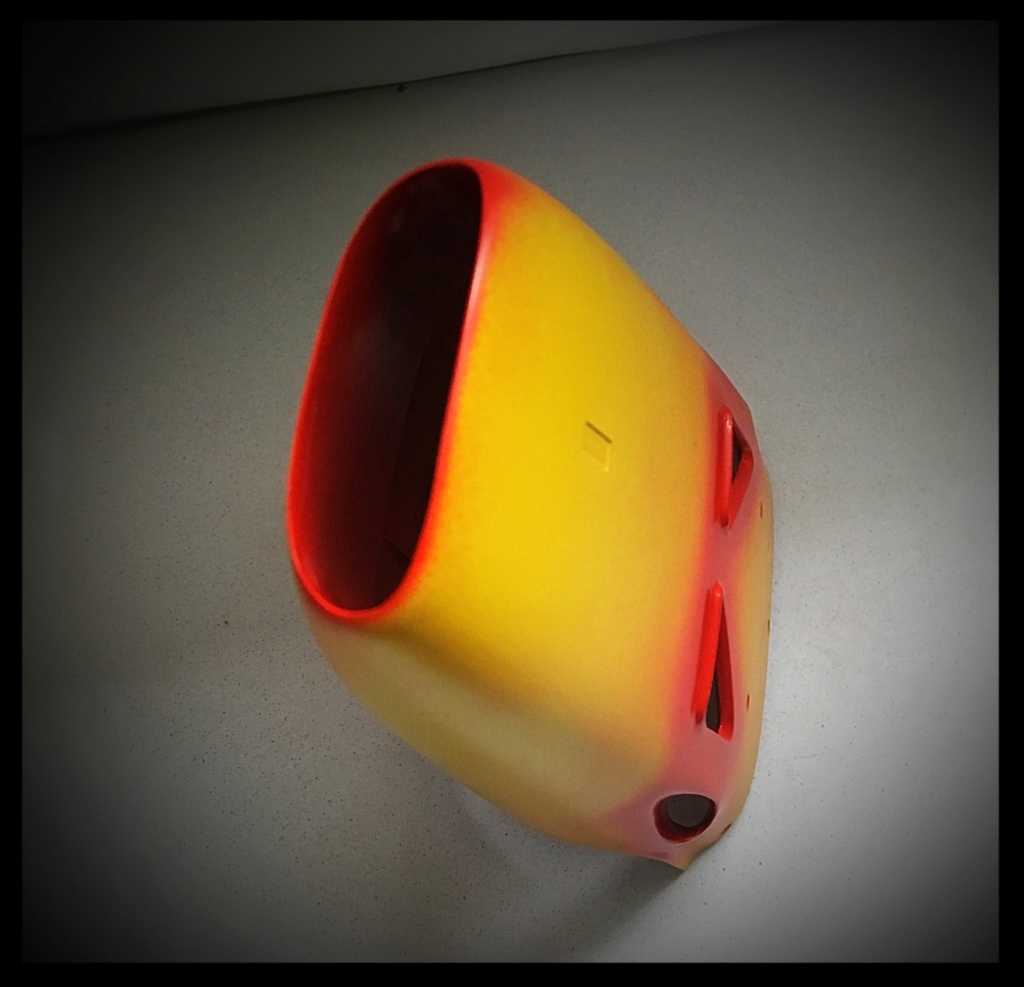

Aaaaannd, there is a new kid in town!

0.3 flat pattern: tested today and happy with the result.

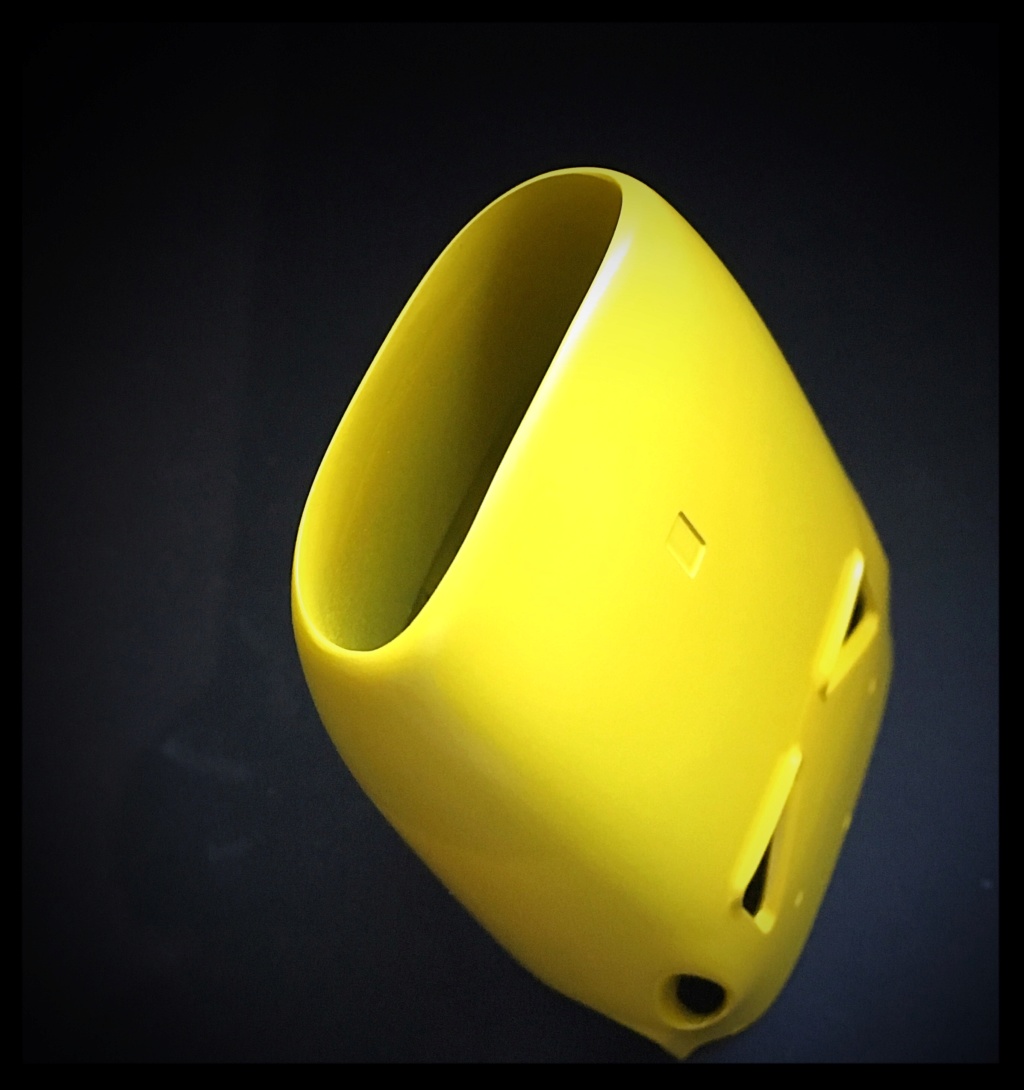

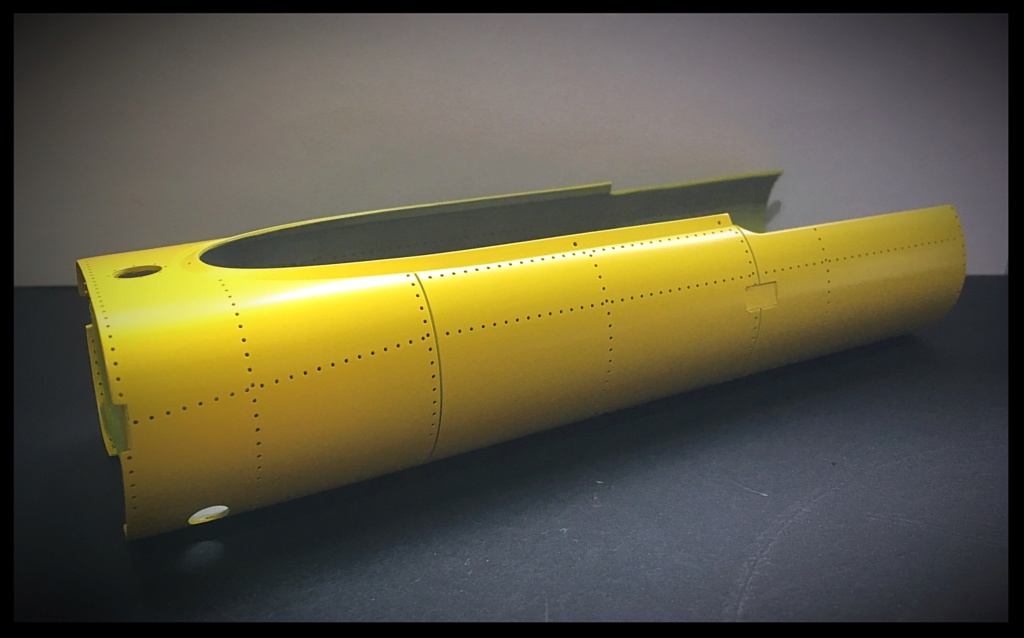

A last sanding session on the metal body, then:

- Primer,

- Giallo Modena,

- Rosso Corsa.

Also started to spray primer on the first 200 metal rivets.

400 left to do... before GM&RC.

Few of them will be White.

Decals session

Once dry they are cleaned as well as the surrounding area.

Then holes are done in the decals.

Preparation of the front parts.

Difference between parts done and TBD.

Tanks temporarily installed:

A bit closer

Coils and ignition system done:

Exhaust Test fit:

Preparation and installation of the hose and the "serflex" on the pipes of the cooling system.

The tightening of the collar is simulated using aluminum foil and a piece of welding wire.

Same preparation for the 2 cooling scoops.

Test and alignment of the 1/2 rear axles and rods of the anti-roll bar.

I wanted to rebuild the anti roll bar with brass, but the original is good and almost hidden behind the tank...

The grills are installed on the radiator and the simulated inside tubing is still visible.

A new Sandow will replace the white metal part.

Difference between before and after work on white metal parts.

The small bucket doesn’t belong to the 312F1...but to a Tipo 500.

I wanted to install thin aluminum sheet on the structure.

I finally managed to finish the ignition coils system, after a last modification.

Small brass bridges of 0.5 were installed on each side of the water / oil tank to hold the "bungee cord" in place after having stretched it.

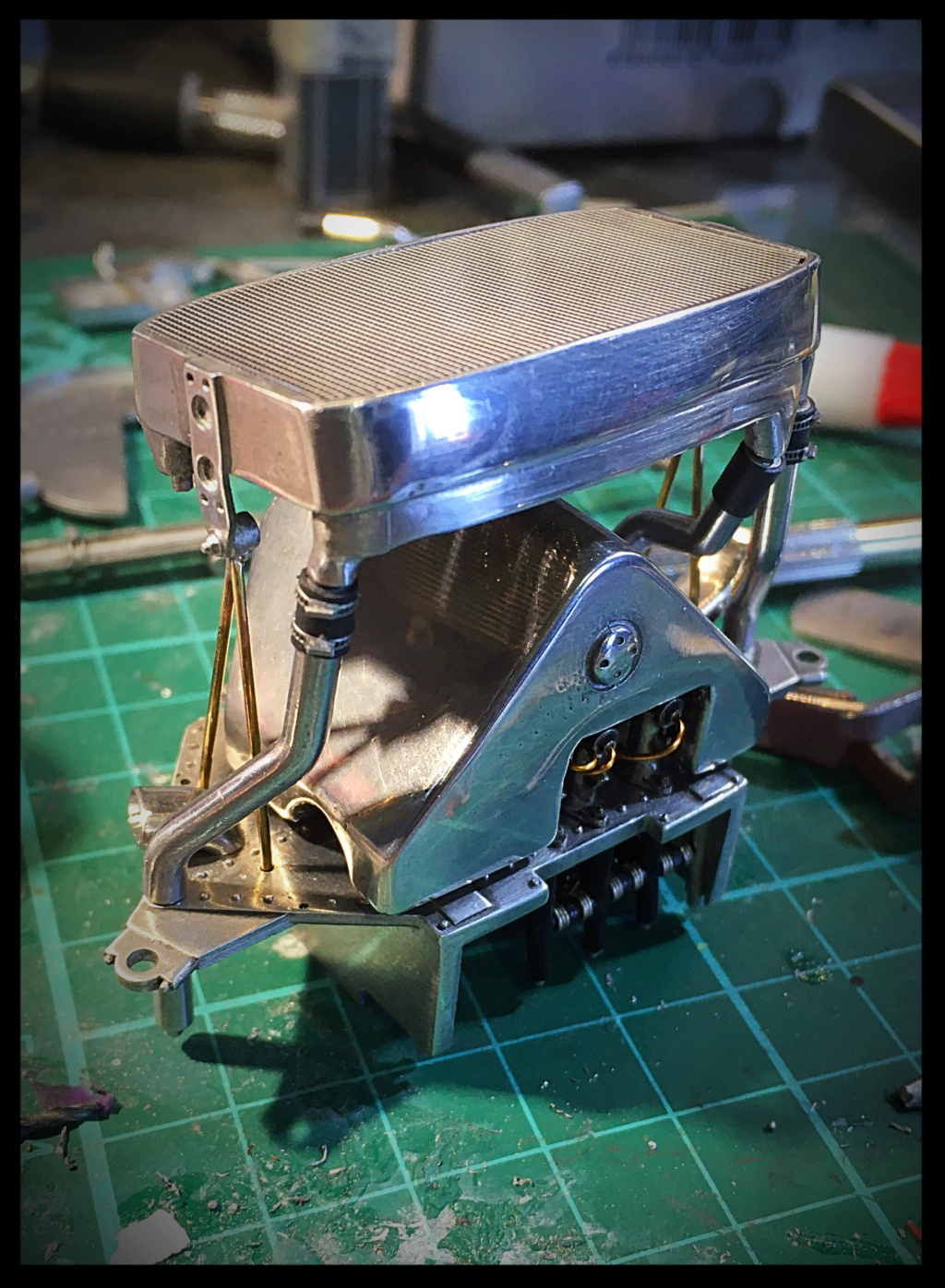

There was a problem with the length of the radiator supports, I redid them in brass of 0.8 which I brazed with silver solder.

It was also time to paint the radiator(s): No more beautiful polished metal appearance and place for brass.

... And decided to represent the welded appearance of brass radiators.

Metalcote Alu, oils ...

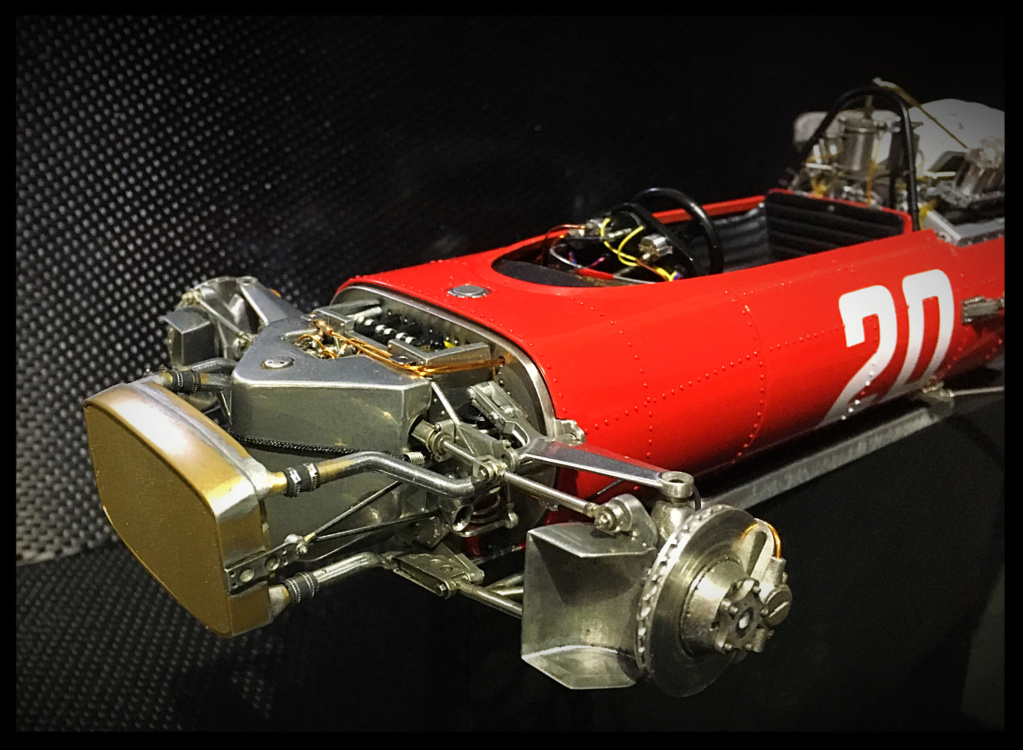

A blank assembly of the various components of the rear axle and the exhausts to confirm that we are going in the right direction

It only remains to connect the lines to the master cylinder of the front brakes, this is done for the clutch and the rear.

Just have to finalize the assembly of the elements

I touched up the varnish and painted the underside of the hull.

I decided to make the fuel cells connection faucet. It's made of white metal and a spare / modified distributor.

Working on the dashboard.

installed

the lower body part is now done and weathered

All the body parts are now fully dry. White dust is coming from the varnish dust while reopening the rivet holes.

The CAVALLINO is installed on the nose and the original decal is replaced by an "enamelled" badge from an old MFH reference.

Fit test of the front area.

Starting the riveting process...

Ainsi que sur les platines d'ancrage des tirants de suspension:

Decisive assembly if any, the engine is assembled with the chassis.

Assy is done with Loctite 401 and reinforced, as usual, with screws, washers and bolts.

The inside of the bathtub is done, the seat is finally installed as the side water pipe and the gear selector.

The fuel valve is installed.

I made and temporary installed the soft fuel cell. We call it Bladder for aircrafts...

It was not modeled by MFH and, even if the polished metal part is nice, the front end was too empty for my taste.

The fuel cell fills the both sides and the front body above the pilot legs.

I made it from self amalgamating tape which depicts pretty well the rubber bladder.

Then, rivets..

I finally installed about 300 and need around 300 more.

So I primed, painted and varnished those ...300 rivets.

Wheels done and Balancing weights installed, made of... Lead.

The front is finished, the back is finished, the middle ... also ...

Some touch-ups and Dzus to install, a clean up and PAF!: It smells of stable!

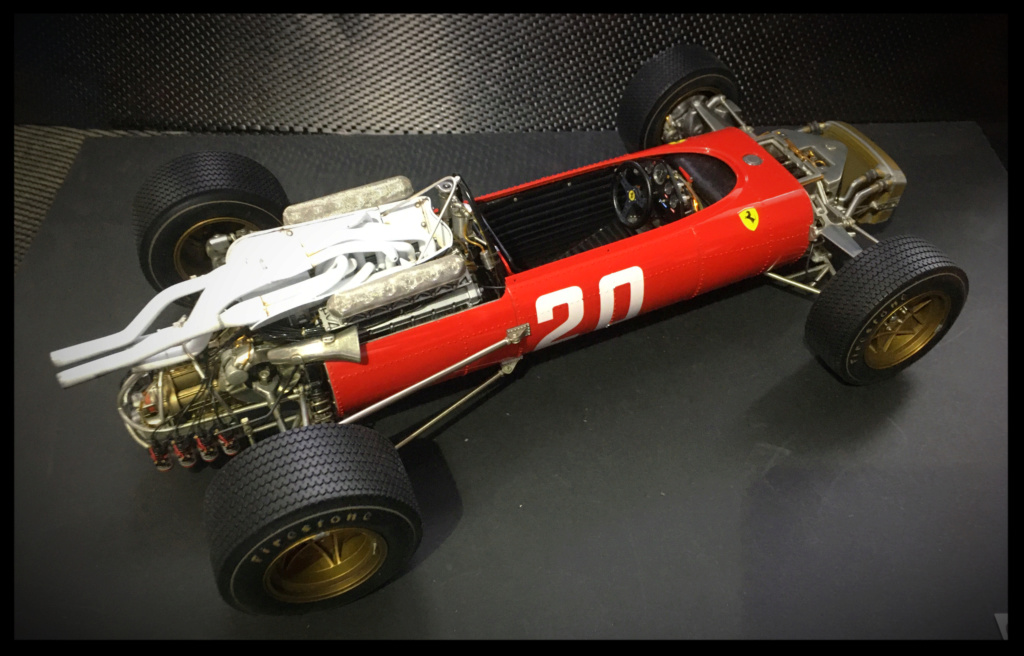

Here are some pictures for which I apologize in advance for the cleanliness of the model.

But it is heavy and the last assemblies require full hand handling.

Et une avec la petite soeur quand même.

That's it, the last touch-ups are done, the last parts installed and the last minute adjustments made.

So I redid the wedges that support the Roaring Beauty with a slightly increased "ground clearance".

They are turned in a 10mm aluminum log for more solidity and stability, the Baby is doing well: 1.4kg

... and decorated with Cavallino.

I connected the last tube and made a little oil to inject it inside.

Here are some images of the finished model.

I will certainly do more later.

I can now call this one done.

I hope you’ll enjoy this WIP build.

Sorry for posting so much pics at the same time.

Pascal

If only closed minds came with closed mouth... |

| 2 L A T E S T R E P L I E S (Newest First) |

| pg265 |

Posted - 10/30/2020 : 09:44:01

Hi,

Thank you. ;)

Well, regarding the rivets, priming, painting & clear coating them was far more hard for my health than inserting them!! :)

If only closed minds came with closed mouth... |

| the.x.man |

Posted - 10/25/2020 : 16:21:53

That is impressive!

How did you manage to retain your sanity while inserting all those rivets?! :o)

__________________________________________________

“The only substitute for cubic inches is more cubic inches!”

~ Max Balchowsky

the.x.man 1:43

|

|

|

|